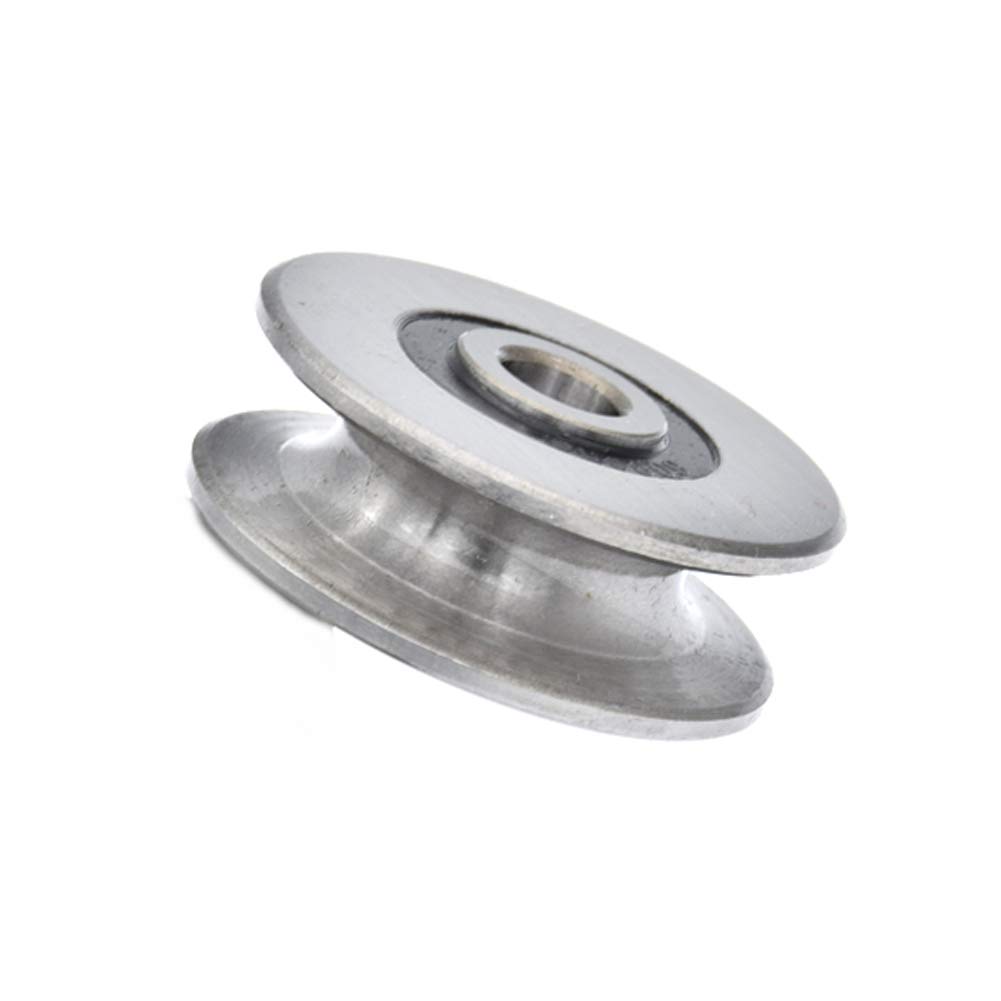

Product Description

Basic Info.

Material :AISI 304 AND AISI 316

| Model No. |

Stainless steel Block Pulley |

| Brand |

HUARUI |

| Design |

Casting |

| Function |

Assemble with Wire rope or Rigging |

| Certification |

SGS |

| For wire rope | No |

| Manufacture |

Casting |

| Color | Silver Color(with polished) |

| Transport Package |

Clean Poly Bags Plus Cartons Plus Pallets |

| Trademark |

HUARUI |

| Production Capacity |

100,000 pcs/Month |

Q: What is material you can supply?

A: Stainless steel 316 or stainless steel 304

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 30-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance CHINAMFG copy of B/L.

If you have another question, pls feel free to contact us at

Contact :Ms. Rita Sun

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | AISI 304, AISI 316 |

|---|---|

| MOQ: | 100 |

| Useful: | Rigging |

| Size: | 4mm |

| Transport Package: | Clean Polybags and Cartons and Pallet |

| Specification: | customized |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do steel pulleys enhance the precision and control of various mechanical operations?

Steel pulleys play a crucial role in enhancing the precision and control of various mechanical operations. Here’s a detailed explanation:

1. Power Transmission:

Steel pulleys are used in conjunction with belts, ropes, or cables to transmit power from one component to another. By utilizing the mechanical advantage of pulleys, it becomes possible to control and regulate the speed, torque, and direction of the transmitted power. This enables precise control over the mechanical operation and facilitates the achievement of desired outcomes.

2. Mechanical Advantage:

Steel pulleys leverage the concept of mechanical advantage to enhance precision and control. The ratio of the diameters or number of grooves in the pulley system determines the mechanical advantage achieved. By selecting the appropriate pulley size and configuration, mechanical operations can be fine-tuned to optimize performance and control variables such as speed, force, and motion.

3. Speed Control:

Steel pulleys, especially those with variable speed capabilities, enable precise speed control in mechanical operations. By adjusting the effective diameter of the pulley, the rotational speed of the driven component can be modified. This is particularly useful in applications where speed regulation is critical, such as in machinery used for manufacturing, processing, or automation.

4. Torque Transfer:

Pulleys facilitate the transfer of torque from the driving component to the driven component. The size and configuration of the pulleys, along with the tension in the connecting belt or cable, determine the torque transmitted. By carefully selecting the pulley system, the torque can be controlled and distributed as required, ensuring precise and reliable torque transfer for mechanical operations.

5. Synchronization:

In certain applications, precise synchronization of mechanical operations is essential. Steel pulleys, when used in conjunction with timing belts or chains, enable accurate synchronization between multiple components. This is commonly seen in applications such as conveyor systems, robotic arms, or printing presses, where coordinated motion is critical for proper functioning and precision.

6. Control over Mechanical Loads:

Steel pulleys provide control over mechanical loads by managing tension and distributing forces. By properly tensioning the belts, ropes, or cables, the pulleys ensure that the load is evenly distributed across the system, minimizing the risk of slippage, excessive wear, or component failures. This control over mechanical loads enhances the precision and reliability of mechanical operations.

7. Reducing Vibration and Noise:

Steel pulleys, when properly designed and balanced, help reduce vibration and noise generated during mechanical operations. Vibration and noise can negatively impact precision and control, leading to suboptimal performance or discomfort. By incorporating features such as dynamic balancing and precision machining, steel pulleys minimize vibrations and contribute to smoother, quieter mechanical operations.

In summary, steel pulleys enhance the precision and control of various mechanical operations by facilitating power transmission, leveraging mechanical advantage, enabling speed control, ensuring torque transfer, enabling synchronization, managing mechanical loads, and reducing vibration and noise. Their versatility and ability to fine-tune mechanical systems make them invaluable components in a wide range of industries and applications.

How do steel pulleys compare to other materials, such as plastic or aluminum, in various scenarios?

Steel pulleys, plastic pulleys, and aluminum pulleys each have their own advantages and considerations in different scenarios. Here’s a detailed comparison:

1. Strength and Durability:

Steel pulleys generally offer higher strength and durability compared to plastic or aluminum pulleys. Steel has excellent load-bearing capacity and can withstand heavy loads and high forces without deformation. Plastic pulleys are lightweight but may have lower strength and may not be suitable for heavy-duty applications. Aluminum pulleys offer a good balance between strength and weight, but they may not be as durable as steel pulleys in certain demanding scenarios.

2. Corrosion Resistance:

Steel pulleys often exhibit better corrosion resistance compared to aluminum pulleys, especially when made from stainless steel or galvanized steel. Plastic pulleys are inherently corrosion-resistant, which makes them suitable for applications where exposure to moisture or chemicals is a concern. Aluminum pulleys may require additional protective coatings or treatments to enhance their corrosion resistance.

3. Weight:

Plastic and aluminum pulleys are generally lighter than steel pulleys. In applications where weight reduction is critical, such as in industries like aerospace or automotive, plastic or aluminum pulleys may be preferred. However, it is important to consider the load requirements and select a material that can handle the anticipated forces without compromising safety or performance.

4. Friction and Wear:

Steel pulleys typically have smoother surfaces and better wear resistance compared to plastic pulleys. The smooth surfaces of steel pulleys reduce friction and wear on the belt or rope, contributing to improved efficiency and longevity. Plastic pulleys may have higher friction coefficients and may require additional lubrication or specialized coatings to reduce wear. Aluminum pulleys can have good wear resistance but may not be as durable as steel pulleys in high-load or abrasive environments.

5. Temperature Resistance:

Steel pulleys generally have better temperature resistance compared to plastic pulleys. Steel can withstand higher temperatures without deformation or loss of strength. Plastic pulleys may have limitations in high-temperature applications due to their lower melting points. Aluminum pulleys have good heat dissipation properties but may experience thermal expansion.

6. Cost:

Steel pulleys are often more cost-effective compared to aluminum pulleys, especially for larger or heavy-duty applications. Plastic pulleys can be cost-effective for certain low-load or non-critical applications. Aluminum pulleys are generally more expensive than steel pulleys but offer advantages in terms of weight savings and specific applications where their properties are advantageous.

7. Noise and Vibration:

Steel pulleys tend to produce less noise and vibration compared to plastic pulleys. Steel’s higher density and rigidity help dampen vibrations and reduce noise levels. Plastic pulleys may generate more noise and vibration, particularly at high speeds or under heavy loads. Aluminum pulleys can offer good vibration damping properties but may not be as effective as steel in certain scenarios.

In summary, the choice between steel, plastic, or aluminum pulleys depends on the specific requirements of the application. Steel pulleys offer superior strength, durability, corrosion resistance, and wear resistance, making them suitable for heavy-duty and demanding scenarios. Plastic pulleys are lightweight, corrosion-resistant, and cost-effective for certain low-load applications. Aluminum pulleys provide a balance between strength and weight, making them advantageous in weight-sensitive applications. Consideration should be given to factors such as load requirements, environmental conditions, temperature, cost, and performance characteristics to determine the most suitable pulley material for a given scenario.

How does the steel construction of pulleys contribute to their durability and strength?

The steel construction of pulleys plays a significant role in their durability and strength. Here’s a detailed explanation:

1. Material Strength:

Steel is renowned for its exceptional strength. It has a high tensile strength, which means it can withstand substantial loads and forces without deforming or breaking. The use of steel in pulley construction ensures that the pulleys can handle heavy loads and high tensions encountered in lifting and tensioning tasks.

2. Resistance to Deformation:

Steel has excellent resistance to deformation under stress. Pulleys experience significant forces and pressures during operation, especially when handling heavy loads. The inherent strength of steel helps prevent deformation, ensuring that the pulleys maintain their shape and functionality over time.

3. Fatigue Resistance:

Steel exhibits high fatigue resistance, meaning it can withstand repeated loading and unloading cycles without failure. In lifting and tensioning tasks, pulleys are subjected to cyclic stress as loads are lifted, lowered, or tensioned. The fatigue resistance of steel ensures that the pulleys can endure these cyclic loads without developing cracks or fractures.

4. Wear Resistance:

Steel pulleys offer excellent wear resistance due to their hardness and surface properties. As ropes, cables, or belts pass over the pulley surfaces, friction occurs, leading to wear. The use of steel, especially alloy steel or case-hardened steel, helps minimize wear and prolong the pulleys’ lifespan, ensuring continued performance and reliability.

5. Corrosion Resistance:

Steel pulleys can be manufactured using corrosion-resistant steel alloys or by applying protective coatings such as galvanization or stainless steel cladding. These measures enhance the pulleys’ resistance to corrosion, making them suitable for applications in harsh environments or industries where exposure to moisture, chemicals, or corrosive substances is common.

6. Structural Integrity:

The structural integrity of steel contributes to the overall durability and strength of pulleys. Steel is a rigid and stable material, capable of maintaining its shape and dimensional stability even under heavy loads or extreme conditions. This structural integrity ensures that the pulleys remain stable and reliable during operation.

7. Design Flexibility:

Steel’s versatility allows for various design options in pulley construction. Manufacturers can design pulleys with different sizes, shapes, and configurations to suit specific application requirements. This flexibility in design ensures that the pulleys can be optimized for strength, load distribution, and efficient operation.

In summary, the steel construction of pulleys contributes to their durability and strength through material strength, resistance to deformation, fatigue resistance, wear resistance, corrosion resistance, structural integrity, and design flexibility. These properties make steel pulleys capable of withstanding heavy loads, resisting wear and corrosion, and maintaining their performance and reliability over an extended period.

editor by CX

2024-04-12