Product Description

Product Description

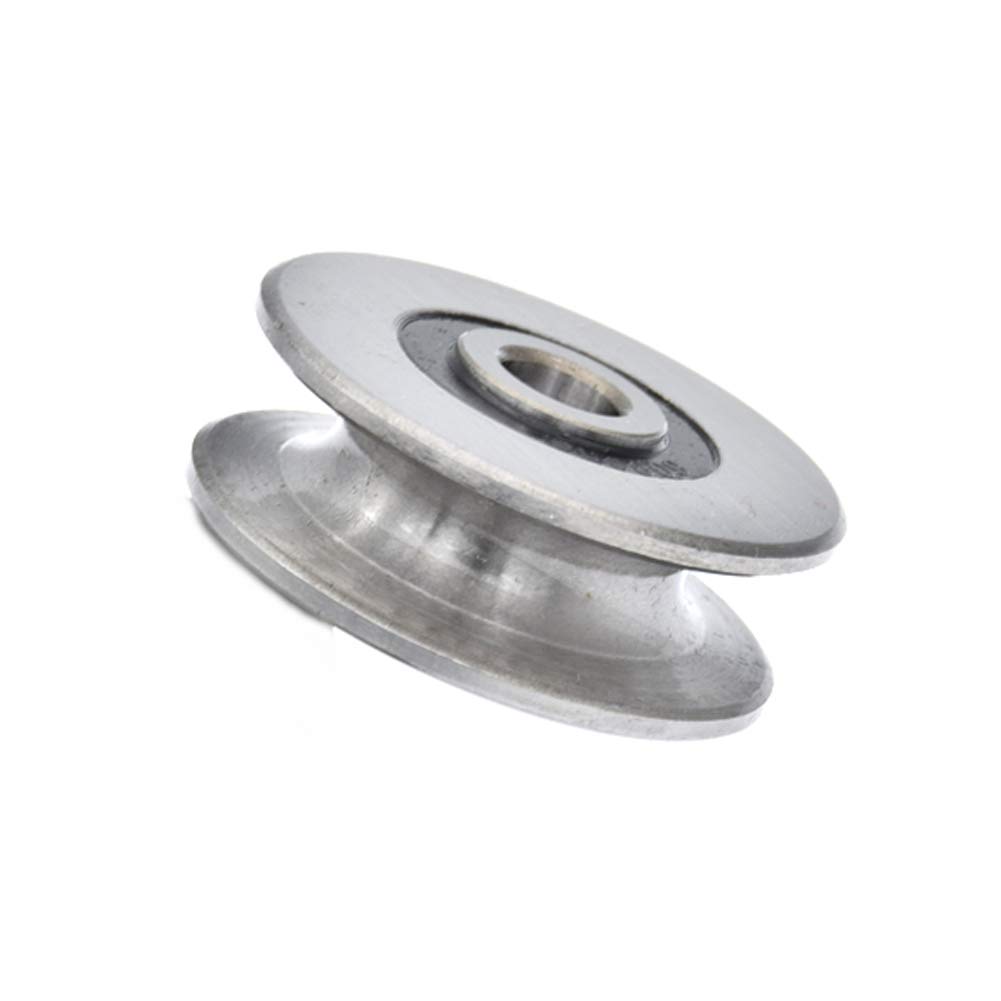

| Production name | door roller, cabinet roller | Material | Stainless Steel |

| Glass thickness | 6-8mm | Glass open-hole size | φ12mm |

| Color | Black | Pulley | φ24-26mm |

| Package | carton, Customized | Mode | Swing |

We support OEM & ODM, Welcome to contact us!

Contact person: Terra

Detailed Photos

Packaging & Shipping

If you want other shipping ways, please contact us for more information.

Company Profile

Professional:

HangZhou SOWO SCIENCE&TECHNOLOGY CO.,LTD is a central enterprises which specialized in developing, design and manufacture of middle high-end shower room hardware accessory and plastic accessory.

Strength:

We are 1 of professional manufacturer of shower accessories in HangZhou city. Our company own production area of 13,000 square meters, professional and technical staff of 30 people, and products showroom of 500 square meters. Our production equipment it has automated high-standard CNC machining centers, intelligent mechanical operation and mold processing center. Minimum monthly capacity completed more than 100,000 sets shower metal parts and plastic parts.

Project:

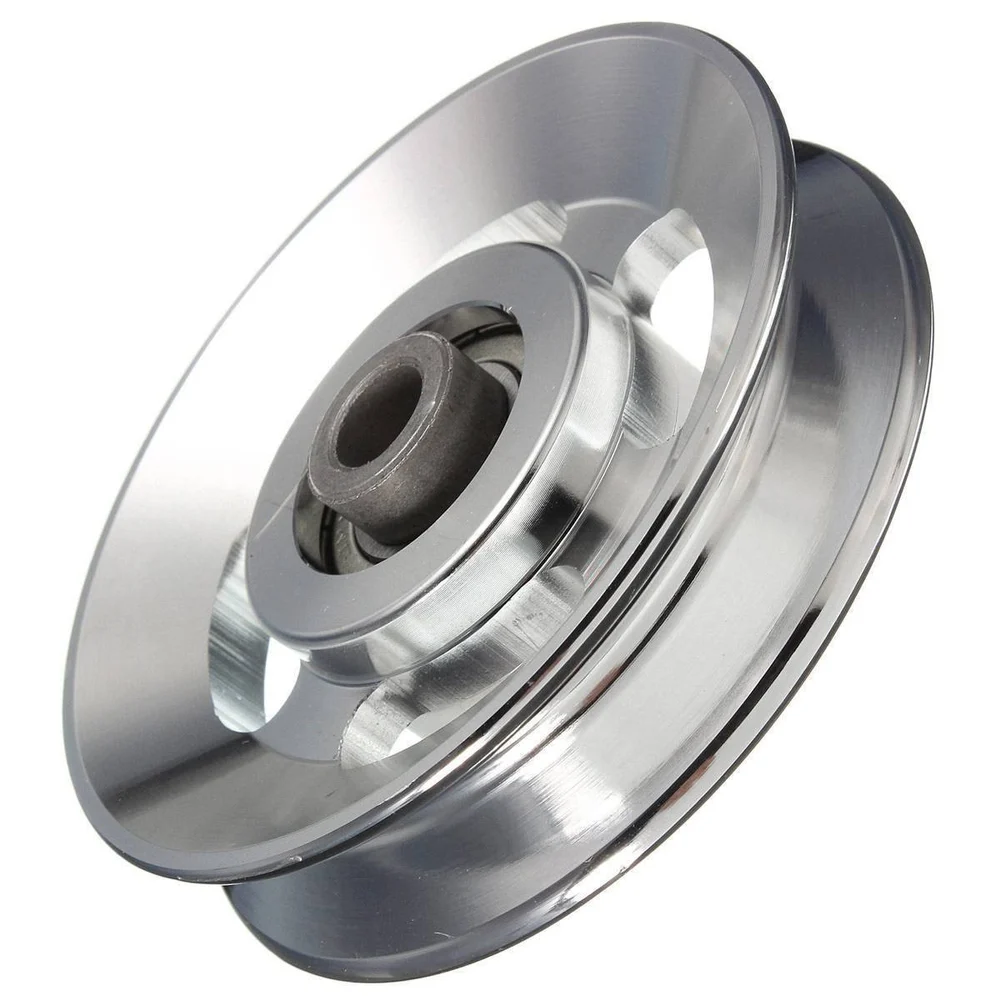

1.Shower room roller pulley product, among of them, 70% of all stainless steel roller pulley based. Zinc, copper and stainless steel hinge, handle and so on thousands of product.

2.Shower room kinds of plastic parts, like corner, slider, anti collision adhesive, position block and so on.

3.Shower room waterproof strip, seal strip and magnetic strip and so on.

Company target:

With a high standard, high-quality concept, we will keep the leader of bathroom accessory fittings industry in the future, and continue to create a modern high-end hardware product in our industry. The former want to do first…

Production

Exhibition

We will attend the China International Kitchen and Bathroom Facilities Exhibition every year at ZheJiang .

FAQ

Q1: Where is your factory located? How can I visit there?

A: Our company is located in HangZhou City, China.

We are really glad to invite you to come to our factory to have a face to face meeting before the bulk order.

Please contact with us when you visit, we will pick you up if near our factory.

Q2: What advantage of your company?

A: We have more than 15 years of experience in R&D, manufacturing, sales and export of sanitary fittings.

Q3: How long is warranty for items?

A: We will provide free spare parts for the bulk order.

Q4: Could you print LOGO/ OEM for items?

A: Sure, we can help you print LOGO/ OEM as your requested.

Q5: How to order?

A: You can order on our MIC directly. If you want to pay by other ways,

Please contact with us online or send a inquiry to us, and we will contact with you ASAP.

Q6: How long is your delivery time?

A: The lead time of our samples is within 3 days.

And for the official order, please let us know the quantities you want, then we will reply you in 1 day.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Spare Parts |

|---|---|

| Warranty: | 2 Years |

| Certification: | CE, ISO |

| Splittable: | Splittable |

| Surface Treatment: | Polished |

| Material: | Steel |

| Samples: |

US$ 5/Pair

1 Pair(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different sizes and configurations of steel pulleys available for specific applications?

Yes, there are different sizes and configurations of steel pulleys available to cater to specific applications. Here’s a detailed explanation:

1. Size Variations:

Steel pulleys are manufactured in various sizes to accommodate different load requirements and belt or cable dimensions. Pulley size is typically defined by its diameter, which can range from small pulleys used in miniature applications to large pulleys used in heavy-duty industrial systems. By offering a range of sizes, manufacturers ensure that there is a suitable pulley size for specific application needs.

2. Configuration Options:

Steel pulleys come in different configurations based on the specific application requirements. Some common configurations include:

- Flat Pulleys: These pulleys have a flat surface and are commonly used with flat belts.

- V-Belt Pulleys: These pulleys have a V-shaped groove and are designed to work with V-belts, providing better grip and power transmission.

- Timing Belt Pulleys: These pulleys have teeth or grooves that match with timing belts, ensuring precise power transmission, especially in applications that require synchronization.

- Idler Pulleys: These pulleys are used to maintain tension in belts, ropes, or cables and change the direction of the belt without transmitting power.

- Variable Speed Pulleys: These pulleys have adjustable groove widths, allowing for variable speed control by changing the effective diameter of the pulley.

- Multiple Groove Pulleys: These pulleys have multiple grooves to accommodate multiple belts or cables, enabling the transmission of power to multiple components.

3. Specialty Pulleys:

In addition to standard configurations, there are specialty pulleys designed for specific applications. For example:

- Wire Rope Pulleys: These pulleys are specifically designed for wire rope applications, providing proper groove dimensions and load distribution for wire ropes.

- High-Speed Pulleys: These pulleys are engineered for high-speed applications, incorporating features such as dynamic balancing and precision machining to ensure reliable operation at high rotational speeds.

- Corrosion-Resistant Pulleys: These pulleys are made from stainless steel or other corrosion-resistant materials, suitable for applications in corrosive environments or industries.

- Customized Pulleys: Manufacturers can also provide custom-designed pulleys tailored to specific application requirements, taking into account factors such as load capacity, speed, dimensions, and environmental conditions.

The availability of different sizes and configurations allows users to select the most appropriate steel pulleys for their specific application needs. This ensures optimal performance, efficient power transmission, and extended pulley life.

How do steel pulleys compare to other materials, such as plastic or aluminum, in various scenarios?

Steel pulleys, plastic pulleys, and aluminum pulleys each have their own advantages and considerations in different scenarios. Here’s a detailed comparison:

1. Strength and Durability:

Steel pulleys generally offer higher strength and durability compared to plastic or aluminum pulleys. Steel has excellent load-bearing capacity and can withstand heavy loads and high forces without deformation. Plastic pulleys are lightweight but may have lower strength and may not be suitable for heavy-duty applications. Aluminum pulleys offer a good balance between strength and weight, but they may not be as durable as steel pulleys in certain demanding scenarios.

2. Corrosion Resistance:

Steel pulleys often exhibit better corrosion resistance compared to aluminum pulleys, especially when made from stainless steel or galvanized steel. Plastic pulleys are inherently corrosion-resistant, which makes them suitable for applications where exposure to moisture or chemicals is a concern. Aluminum pulleys may require additional protective coatings or treatments to enhance their corrosion resistance.

3. Weight:

Plastic and aluminum pulleys are generally lighter than steel pulleys. In applications where weight reduction is critical, such as in industries like aerospace or automotive, plastic or aluminum pulleys may be preferred. However, it is important to consider the load requirements and select a material that can handle the anticipated forces without compromising safety or performance.

4. Friction and Wear:

Steel pulleys typically have smoother surfaces and better wear resistance compared to plastic pulleys. The smooth surfaces of steel pulleys reduce friction and wear on the belt or rope, contributing to improved efficiency and longevity. Plastic pulleys may have higher friction coefficients and may require additional lubrication or specialized coatings to reduce wear. Aluminum pulleys can have good wear resistance but may not be as durable as steel pulleys in high-load or abrasive environments.

5. Temperature Resistance:

Steel pulleys generally have better temperature resistance compared to plastic pulleys. Steel can withstand higher temperatures without deformation or loss of strength. Plastic pulleys may have limitations in high-temperature applications due to their lower melting points. Aluminum pulleys have good heat dissipation properties but may experience thermal expansion.

6. Cost:

Steel pulleys are often more cost-effective compared to aluminum pulleys, especially for larger or heavy-duty applications. Plastic pulleys can be cost-effective for certain low-load or non-critical applications. Aluminum pulleys are generally more expensive than steel pulleys but offer advantages in terms of weight savings and specific applications where their properties are advantageous.

7. Noise and Vibration:

Steel pulleys tend to produce less noise and vibration compared to plastic pulleys. Steel’s higher density and rigidity help dampen vibrations and reduce noise levels. Plastic pulleys may generate more noise and vibration, particularly at high speeds or under heavy loads. Aluminum pulleys can offer good vibration damping properties but may not be as effective as steel in certain scenarios.

In summary, the choice between steel, plastic, or aluminum pulleys depends on the specific requirements of the application. Steel pulleys offer superior strength, durability, corrosion resistance, and wear resistance, making them suitable for heavy-duty and demanding scenarios. Plastic pulleys are lightweight, corrosion-resistant, and cost-effective for certain low-load applications. Aluminum pulleys provide a balance between strength and weight, making them advantageous in weight-sensitive applications. Consideration should be given to factors such as load requirements, environmental conditions, temperature, cost, and performance characteristics to determine the most suitable pulley material for a given scenario.

How does the design of steel pulleys impact their load-bearing capacity and efficiency?

The design of steel pulleys plays a crucial role in determining their load-bearing capacity and efficiency. Here’s a detailed explanation:

1. Diameter and Width:

The diameter and width of a steel pulley directly impact its load-bearing capacity. Larger diameter pulleys distribute the load over a greater surface area, reducing stress and increasing the pulley’s capacity to handle heavier loads. Similarly, wider pulleys provide more contact area for the belt, rope, or cable, allowing for improved load distribution and increased load-bearing capacity.

2. Groove Profile:

The groove profile of a steel pulley affects its efficiency and load-bearing capacity. Different groove profiles, such as V-shaped, U-shaped, or flat, are designed to accommodate specific types of belts, ropes, or cables. The groove profile should match the corresponding belt or cable to ensure proper engagement, minimize slippage, and maximize the load-carrying capability of the pulley.

3. Flanges and Guards:

Pulleys can be designed with flanges or guards on the sides to prevent the belt, rope, or cable from slipping off during operation. Flanges provide guidance and keep the material being conveyed centered on the pulley, enhancing the load-bearing capacity and efficiency. Guards also protect the belt or cable from external elements, reducing the risk of damage and improving overall performance.

4. Bearing Type and Arrangement:

The type and arrangement of bearings in a steel pulley significantly impact its load-bearing capacity and efficiency. High-quality bearings, such as deep groove ball bearings or roller bearings, reduce friction and enable smooth rotation, enhancing the efficiency of power transmission. Proper bearing arrangement, such as using multiple bearings or incorporating bearing supports, ensures optimal load distribution and improves the pulley’s ability to handle higher loads.

5. Material Selection:

The choice of steel material for pulley construction affects both load-bearing capacity and efficiency. High-strength steel alloys or heat-treated steels provide greater load-carrying capacity and resistance to wear or deformation. The material should be selected based on the specific application requirements, considering factors such as load magnitude, operating conditions, and environmental factors.

6. Balanced Design:

A well-balanced design is essential for efficient and reliable operation. Imbalances in the pulley design can cause vibration, increased wear, and reduced load-bearing capacity. Proper balancing techniques, such as counterweights or precision machining, ensure smooth rotation, minimize stress on the pulley and associated components, and optimize load-bearing capacity.

7. Alignment and Installation:

The proper alignment and installation of steel pulleys are critical for their load-bearing capacity and efficiency. Pulleys should be aligned accurately with the drive system to prevent misalignment-induced stress and premature wear. Correct installation techniques, such as applying proper tension to belts or cables, ensure optimal power transmission and efficient load-bearing performance.

In summary, the design of steel pulleys directly impacts their load-bearing capacity and efficiency through factors such as diameter and width, groove profile, flanges and guards, bearing type and arrangement, material selection, balanced design, and proper alignment and installation. By considering these design aspects, manufacturers can optimize the performance and capabilities of steel pulleys, enabling them to handle higher loads, minimize energy losses, and operate with greater efficiency.

editor by CX

2024-04-22