Product Description

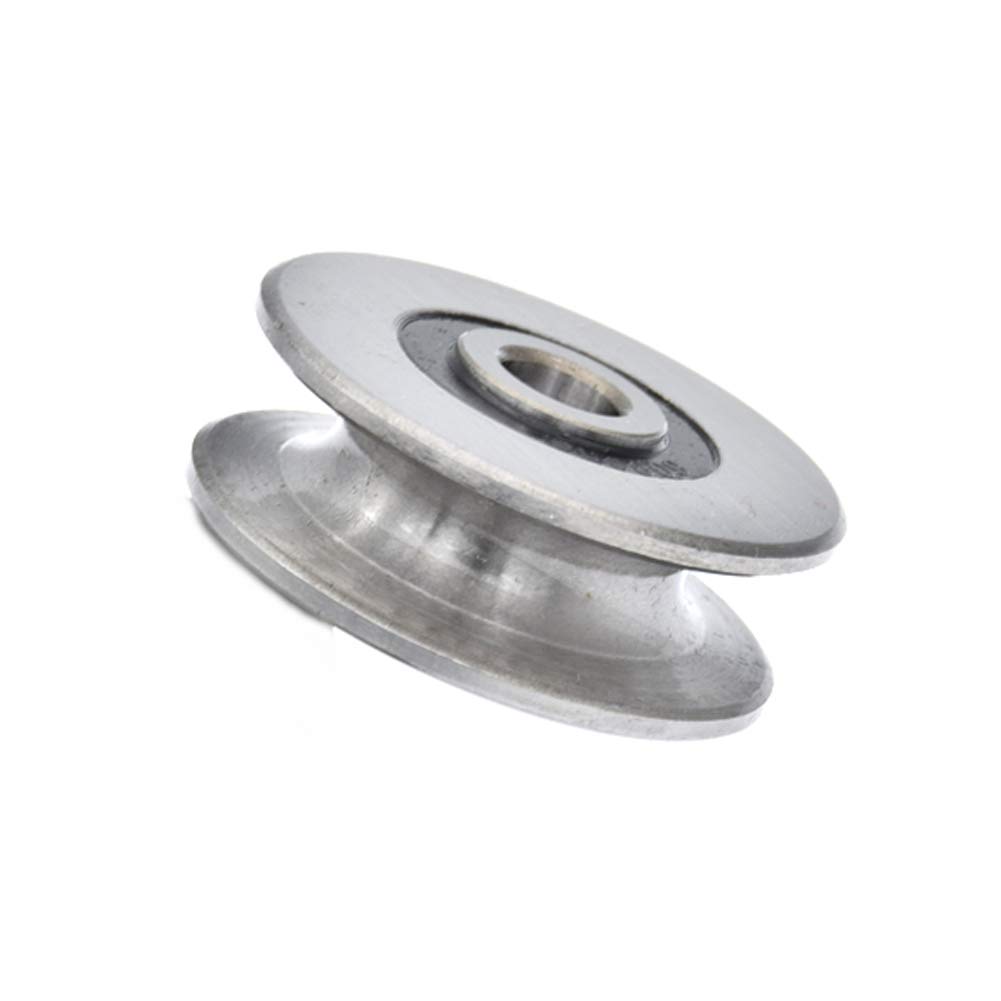

Synchronous Wheel Manufacturer Stainless Steel Timing Belt Pulleys For Packaging Industry

Advantages:

1. Good quality products

2. Competitive prices

3. Fast delivery

4. Best after-sale service

5. Brand: HeFa or OEM/ ODM

6.Normal torque drive timing pulley:MXL/XL/L/H

7.High torque drive gear type: S2M/ S3M/ S5M/ S8M/ HTD3M /HTD5M/ HTD8M/P2M/P3M/P5M/P8M

8.High precision position drive gear type:2GT/3GT/5GT/8YU

9.Light load drive gear type:T5/T10

10.Heavy load drive gear type:AT5/AT10

Product Parameters

| Product | Timing Belt Pulley & idler pulley |

| Teeth type | Normal Torque Drive Type:MXL,XL,L,H,XH,XXH High Torque Drive Type:S2M,S3M,S5M,S8M,HTD2M,HTD3M,HTD5M,HTD8M,P2M,P3M,P5M,P8M High Precision Position Drive Type:2GT,3GT,5GT,8YU Light Load Drive Type:T5,T10,T20 Heavy Load Drive Type:AT5,AT10,AT20 |

| Basic shape | Type A,Type B,Type D,Type E,Type F,Type K |

| surface treatment | Natural color anodizing,Black anodizing,Hard anodizing,Ni-plating,Blackening |

| Material | 6061(aluminum),S45C(45# steel),SUS304(Stainless steel) |

| Bore | Pilot bore, Taper bore and Customized bore. |

| testing equipment | projecting apparatus,salt spray test,durometer,and coating thickness tester,2D projector |

| producing equipment | CNC machine,automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Application industry | Robot industry,Medical industry,Making machine industry,Automation industry,3C industry equipment,Packaging industry,UAV industry,New energy industry. |

Company Profile

Packaging & Shipping

| lead time | 10-15 working days as usual,30days in busy season,it will based on the detailed order quantity |

| Delivery of samples | by DHL,Fedex,UPS,TNT,EMS |

FAQ

| Main markets | North America, South America,Eastern Europe,Weat Europe,North Europe.South Europe,Asia |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you!! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Stainless Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, New Energy Industry |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can steel pulleys be customized or modified to meet specific load requirements?

Yes, steel pulleys can be customized or modified to meet specific load requirements. Here’s a detailed explanation:

1. Size and Dimensions:

Steel pulleys can be customized in terms of size and dimensions to accommodate specific load requirements. The diameter, width, and overall geometry of the pulley can be adjusted to ensure optimal load-bearing capacity and compatibility with the application. Customization allows for precise matching of the pulley dimensions to the load demands, promoting efficient and reliable operation.

2. Material Selection:

The choice of steel material for the pulley can be tailored based on specific load requirements. Different steel alloys and compositions have varying strength, hardness, and wear resistance properties. By selecting the appropriate steel material, the pulley can be optimized to handle higher loads, resist wear, and withstand harsh operating conditions.

3. Bearing Type:

Steel pulleys can be customized with different bearing types to handle specific load requirements. The bearing type plays a crucial role in supporting the load and facilitating smooth rotation of the pulley. Options such as deep groove ball bearings, tapered roller bearings, or spherical roller bearings can be selected based on load capacity, rotational speed, and environmental conditions.

4. Coatings and Surface Treatments:

Coatings and surface treatments can be applied to steel pulleys to enhance their load-bearing capabilities. For example, pulleys can be coated with corrosion-resistant materials or treated with specialized coatings to reduce friction and wear. These customized surface treatments improve the overall performance and longevity of the pulley, especially in demanding load conditions.

5. Reinforcements and Reinforcement Materials:

In situations where standard steel pulleys may not meet the desired load requirements, reinforcements can be added or alternative reinforcement materials can be used. Reinforcing the pulley structure with additional steel components or incorporating materials such as carbon fiber or reinforced polymers can significantly increase the load capacity and strength of the pulley.

6. Dynamic Balancing:

Customization of steel pulleys can include dynamic balancing, which is essential for high-speed applications or when precise rotation is required. Dynamic balancing ensures that the pulley’s mass is evenly distributed, minimizing vibrations and reducing the risk of premature wear or component failure due to unbalanced forces.

7. Specialized Designs:

In some cases, specialized designs or modifications may be required to meet specific load requirements. This could involve incorporating features such as reinforced hub sections, flanges, or additional grooves to distribute the load more effectively. Custom designs can be created through engineering analysis and collaboration between the pulley manufacturer and the end-user.

It’s important to note that customization and modification of steel pulleys should be done in consultation with experienced engineers or pulley manufacturers. They can provide expertise in assessing the load requirements, selecting suitable customization options, and ensuring compliance with relevant industry standards and safety guidelines.

In summary, steel pulleys can be customized or modified in terms of size, material, bearing type, coatings, reinforcements, dynamic balancing, and specialized designs to meet specific load requirements. Customization enhances the load-bearing capacity, durability, and overall performance of steel pulleys, making them suitable for a wide range of applications in various industries.

How does the quality and precision of steel pulley components affect their performance?

The quality and precision of steel pulley components have a significant impact on their performance. Here’s a detailed explanation:

1. Load Capacity:

High-quality steel pulley components are engineered to withstand specific load capacities. The use of high-grade steel with appropriate strength and hardness ensures that the pulley can handle the intended loads without deformation or failure. Precision in manufacturing processes ensures consistent performance and reliable load-bearing capabilities.

2. Durability and Longevity:

Precision manufacturing techniques and the use of high-quality materials enhance the durability and longevity of steel pulley components. Components manufactured to precise specifications are less prone to wear, fatigue, and premature failure. High-quality steel with proper heat treatment and surface finishes improves resistance to corrosion, abrasion, and other forms of degradation, extending the lifespan of the pulley.

3. Smooth Operation:

Precision in the design and manufacturing of steel pulley components contributes to smooth operation. Well-machined components ensure proper alignment, balance, and concentricity, reducing friction and minimizing vibrations. Smooth operation enhances efficiency, reduces power losses, and extends the lifespan of associated equipment, such as belts, bearings, and drives.

4. Reduction of Noise and Vibration:

Poorly manufactured or low-quality steel pulley components can generate excessive noise and vibration during operation. Precision manufacturing techniques, such as accurate machining and balancing, help minimize vibrations and noise levels. This improves operator comfort, reduces equipment fatigue, and promotes a safer and more productive work environment.

5. Belt Tracking and Tensioning:

Precision in the design and manufacture of steel pulley components plays a crucial role in belt tracking and tensioning. Components with accurate dimensions and smooth surfaces ensure proper alignment and contact with the belt, facilitating efficient power transmission and minimizing belt slippage. Precise tensioning mechanisms and adjustments allow for optimal belt tension, reducing wear and extending belt life.

6. Compatibility and Interchangeability:

High-quality steel pulley components are designed and manufactured to precise standards, ensuring compatibility and interchangeability with other components and systems. This allows for easier installation, replacement, and maintenance. Components that meet standardized dimensions and tolerances can be readily sourced and integrated into existing equipment or systems.

7. Safety and Reliability:

The quality and precision of steel pulley components directly influence the safety and reliability of the overall system. Components manufactured to high standards minimize the risk of sudden failures, malfunctions, or accidents. Reliable performance of pulley components enhances the overall reliability of equipment and reduces the likelihood of costly downtime or maintenance.

In summary, the quality and precision of steel pulley components are critical factors in determining their performance. High-quality components offer superior load capacity, durability, smooth operation, reduced noise and vibration, optimized belt tracking and tensioning, compatibility and interchangeability, as well as enhanced safety and reliability. It is essential to source steel pulley components from reputable manufacturers that adhere to stringent quality control measures and employ precision manufacturing techniques.

What are steel pulleys, and how are they used in various applications?

Steel pulleys are mechanical devices made primarily from steel that are used to guide or redirect ropes, cables, or belts in various applications. Here’s a detailed explanation:

1. Construction and Engineering:

In construction and engineering, steel pulleys are commonly used in hoisting and lifting systems. They provide a stable and durable mechanism for raising and lowering heavy loads, such as construction materials, equipment, or machinery. Steel pulleys used in these applications are designed to withstand high loads and harsh operating conditions.

2. Industrial Machinery and Manufacturing:

Steel pulleys find extensive use in industrial machinery and manufacturing processes. They are employed in conveyor systems to move materials or products along assembly lines. Steel pulleys with different diameters and groove configurations are used to facilitate belt or chain movement, ensuring efficient and reliable material handling.

3. Automotive and Transportation:

In the automotive and transportation industries, steel pulleys are utilized in various applications. They are commonly found in engines as part of the accessory drive system, where they drive components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure smooth operation and reliable power transmission in these critical systems.

4. Gym and Fitness Equipment:

Steel pulleys are integral components of gym and fitness equipment, such as cable machines or weightlifting systems. They enable smooth and controlled movement of cables or belts, allowing users to perform exercises safely and effectively. Steel pulleys used in fitness equipment are designed to withstand repetitive loads and provide long-lasting performance.

5. Material Handling and Rigging:

Steel pulleys play a crucial role in material handling and rigging applications. They are used in systems such as cranes, winches, and lifting equipment to redirect cables or ropes, enabling the lifting and movement of heavy objects. Steel pulleys in these applications are engineered to handle substantial loads and ensure safe and efficient material handling.

6. Entertainment and Theatrical Rigging:

In the entertainment industry, steel pulleys are utilized in theatrical rigging systems. They are employed to control the movement of stage components, lighting fixtures, curtains, and other theatrical elements. Steel pulleys in this context must meet stringent safety standards and provide precise positioning and smooth operation.

7. Recreational Activities:

Steel pulleys are also utilized in various recreational activities. For example, in zip line courses or rope courses, steel pulleys are used to guide participants along the course safely. In rock climbing, steel pulleys may be employed as part of hauling systems or belay devices. These pulleys are designed to withstand high forces and ensure reliable performance in adventurous settings.

Steel pulleys offer strength, durability, and reliability in a wide range of applications. Their ability to handle heavy loads, provide smooth operation, and withstand harsh conditions makes them indispensable in industries such as construction, manufacturing, automotive, fitness, entertainment, and recreational activities.

editor by CX

2024-05-06