Product Description

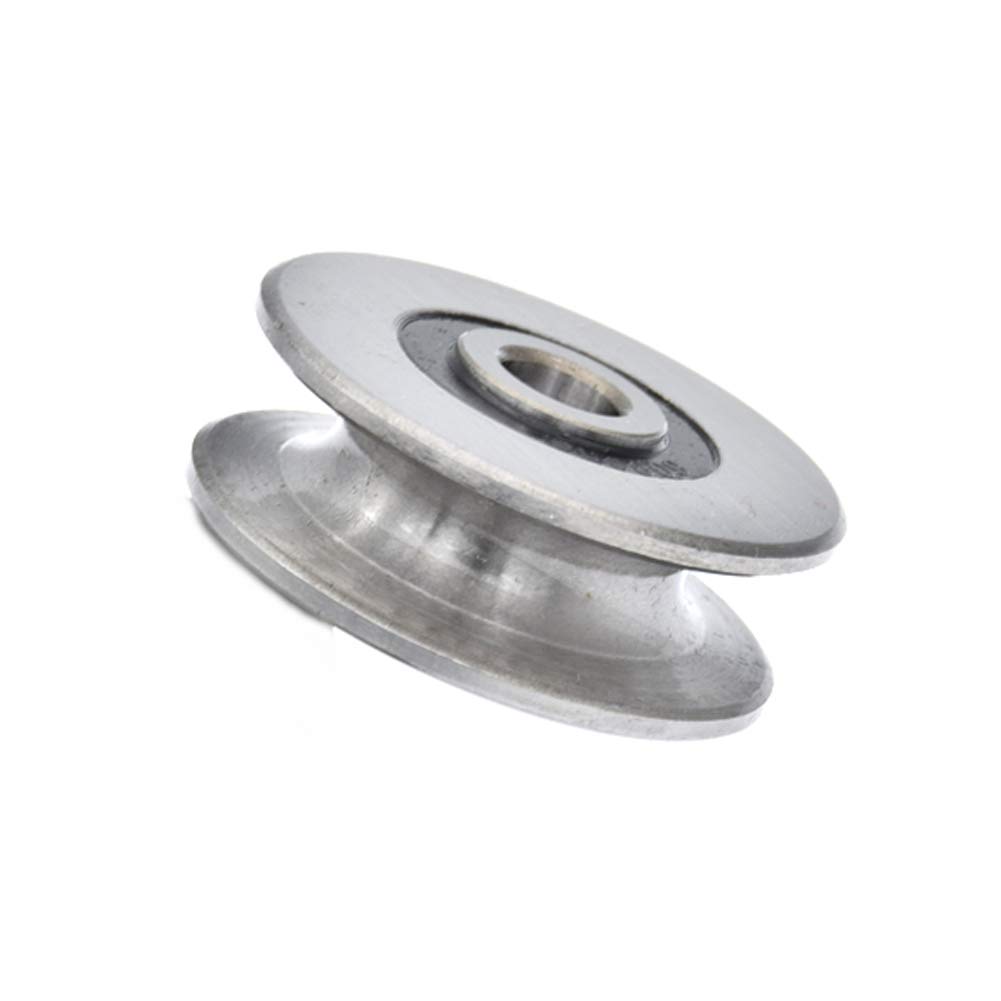

Detailed Photos

Product Description

| Item No. | Door and Window Pulley Roller |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings. Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller’s outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they’re made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click “Contact supplier” to contact us, or “Call us” with any questions that you may have.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the role of steel pulleys in the mining and construction industries?

Steel pulleys play a crucial role in the mining and construction industries, contributing to the efficient and reliable operation of various equipment and systems. Here’s a detailed explanation:

1. Conveyor Systems:

In both mining and construction, conveyor systems are extensively used for the transportation of bulk materials, such as ores, aggregates, and construction materials. Steel pulleys are integral components of conveyor systems, providing support, guidance, and tensioning for conveyor belts. They help facilitate the smooth movement of materials, ensuring efficient material handling and reducing manual labor requirements.

2. Hoisting and Lifting Equipment:

In mining and construction, hoisting and lifting equipment, such as cranes, winches, and elevators, are essential for lifting heavy loads and transporting them vertically or horizontally. Steel pulleys are critical components in these systems, enabling the transmission of power and torque to lift and move heavy loads safely and efficiently. They are used in conjunction with wire ropes, cables, or chains to create mechanical advantage and control the lifting process.

3. Drilling and Excavation Machinery:

In mining and construction, drilling and excavation machinery, such as drilling rigs, tunnel boring machines, and excavators, are employed for digging, drilling, and creating openings in the ground. Steel pulleys contribute to the operation of these machines by facilitating the movement and control of cables, ropes, or belts that drive the drilling or excavation mechanisms. They help transmit power, control speed, and guide the movement of the drilling or excavation components.

4. Crushing and Screening Equipment:

In mining and construction projects, crushing and screening equipment is used to process raw materials into desired sizes and shapes. Steel pulleys are utilized in crushers, screens, and other processing machinery to drive the rotational motion of belts or pulley systems. They help maintain proper tension, control the speed of the components, and ensure efficient material processing.

5. Power Transmission Systems:

Steel pulleys are integral to power transmission systems in mining and construction equipment. They are used in conjunction with belts, chains, or gears to transmit power from engines or motors to various components, such as pumps, fans, or compressors. Steel pulleys enable precise control over speed, torque, and power distribution, ensuring efficient and reliable operation of the equipment.

6. Tensioning and Tracking:

In mining and construction applications, belts, ropes, or cables connected to various equipment and systems require proper tensioning and tracking to ensure reliable performance. Steel pulleys with tensioning devices, such as take-up systems or adjustable pulleys, help maintain the desired tension and alignment of the belts or cables. This promotes optimal operation, reduces wear, and minimizes the risk of slippage or misalignment.

7. Durability and Reliability:

Mining and construction environments are often demanding, with harsh conditions, heavy loads, and intensive operations. Steel pulleys are chosen for their durability and reliability in such challenging environments. They are designed to withstand high loads, resist wear, and operate consistently under demanding conditions, contributing to the overall reliability and longevity of mining and construction equipment.

In summary, steel pulleys play a vital role in the mining and construction industries by contributing to the efficient operation of conveyor systems, hoisting and lifting equipment, drilling and excavation machinery, crushing and screening equipment, power transmission systems, and tensioning/tracking applications. Their durability, reliability, and ability to handle heavy loads make them indispensable components in these industries.

What environmental factors should be considered when using steel pulleys in outdoor applications?

When using steel pulleys in outdoor applications, several environmental factors should be considered. Here’s a detailed explanation:

1. Corrosion:

Outdoor environments often expose steel pulleys to moisture, humidity, rain, and other corrosive elements. It is crucial to select pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, to prevent rust and corrosion. Regular inspection and maintenance of pulleys, including cleaning and applying protective coatings, can help mitigate the effects of corrosion.

2. UV Exposure:

Steel pulleys used in outdoor applications are exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV rays can degrade the materials and weaken the pulleys over time. UV-resistant coatings or finishes can be applied to the pulleys to protect them from UV damage. Additionally, using pulley covers or enclosures can provide additional UV protection.

3. Temperature Extremes:

Outdoor environments can experience temperature extremes, including high heat or freezing temperatures. Steel pulleys should be designed to withstand these temperature variations without compromising their structural integrity. Pulleys made from materials with high-temperature resistance, such as heat-treated steels or alloys, can be employed in applications with elevated temperatures. In cold climates, consideration should be given to the potential effects of low temperatures on pulley performance, such as reduced lubrication effectiveness.

4. Dust and Debris:

Outdoor environments often contain dust, dirt, and debris, which can accumulate on steel pulleys and affect their operation. Regular cleaning and maintenance of the pulleys are essential to prevent the buildup of contaminants that can cause increased friction and wear. Protective covers or seals can be used to minimize the ingress of dust and debris into the pulley components.

5. Moisture and Humidity:

Moisture and humidity in outdoor environments can impact the performance of steel pulleys. Excessive moisture can lead to corrosion, rust, or the deterioration of lubricants. It is important to consider the environmental conditions and choose pulleys that are designed to withstand moisture and humidity. Sealed bearings, waterproof coatings, and proper lubrication can help protect the pulleys from moisture-related issues.

6. Vibration and Shock:

Outdoor applications may involve machinery or equipment that generates vibration and shock loads. Steel pulleys should be designed to withstand these dynamic forces without failure or premature wear. Reinforced construction, precision balancing, and appropriate mounting techniques can help minimize the impact of vibration and shock on the pulleys.

7. Environmental Regulations:

Compliance with environmental regulations is crucial when using steel pulleys in outdoor applications. Certain environments may have specific regulations related to pollution prevention, noise levels, or the use of hazardous materials. It is important to ensure that the selection, installation, and operation of steel pulleys align with applicable environmental regulations.

By considering these environmental factors and taking appropriate measures, such as selecting corrosion-resistant materials, applying protective coatings, regular maintenance, and adhering to environmental regulations, the performance and longevity of steel pulleys in outdoor applications can be optimized.

What are steel pulleys, and how are they used in various applications?

Steel pulleys are mechanical devices made primarily from steel that are used to guide or redirect ropes, cables, or belts in various applications. Here’s a detailed explanation:

1. Construction and Engineering:

In construction and engineering, steel pulleys are commonly used in hoisting and lifting systems. They provide a stable and durable mechanism for raising and lowering heavy loads, such as construction materials, equipment, or machinery. Steel pulleys used in these applications are designed to withstand high loads and harsh operating conditions.

2. Industrial Machinery and Manufacturing:

Steel pulleys find extensive use in industrial machinery and manufacturing processes. They are employed in conveyor systems to move materials or products along assembly lines. Steel pulleys with different diameters and groove configurations are used to facilitate belt or chain movement, ensuring efficient and reliable material handling.

3. Automotive and Transportation:

In the automotive and transportation industries, steel pulleys are utilized in various applications. They are commonly found in engines as part of the accessory drive system, where they drive components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure smooth operation and reliable power transmission in these critical systems.

4. Gym and Fitness Equipment:

Steel pulleys are integral components of gym and fitness equipment, such as cable machines or weightlifting systems. They enable smooth and controlled movement of cables or belts, allowing users to perform exercises safely and effectively. Steel pulleys used in fitness equipment are designed to withstand repetitive loads and provide long-lasting performance.

5. Material Handling and Rigging:

Steel pulleys play a crucial role in material handling and rigging applications. They are used in systems such as cranes, winches, and lifting equipment to redirect cables or ropes, enabling the lifting and movement of heavy objects. Steel pulleys in these applications are engineered to handle substantial loads and ensure safe and efficient material handling.

6. Entertainment and Theatrical Rigging:

In the entertainment industry, steel pulleys are utilized in theatrical rigging systems. They are employed to control the movement of stage components, lighting fixtures, curtains, and other theatrical elements. Steel pulleys in this context must meet stringent safety standards and provide precise positioning and smooth operation.

7. Recreational Activities:

Steel pulleys are also utilized in various recreational activities. For example, in zip line courses or rope courses, steel pulleys are used to guide participants along the course safely. In rock climbing, steel pulleys may be employed as part of hauling systems or belay devices. These pulleys are designed to withstand high forces and ensure reliable performance in adventurous settings.

Steel pulleys offer strength, durability, and reliability in a wide range of applications. Their ability to handle heavy loads, provide smooth operation, and withstand harsh conditions makes them indispensable in industries such as construction, manufacturing, automotive, fitness, entertainment, and recreational activities.

editor by CX

2024-04-24