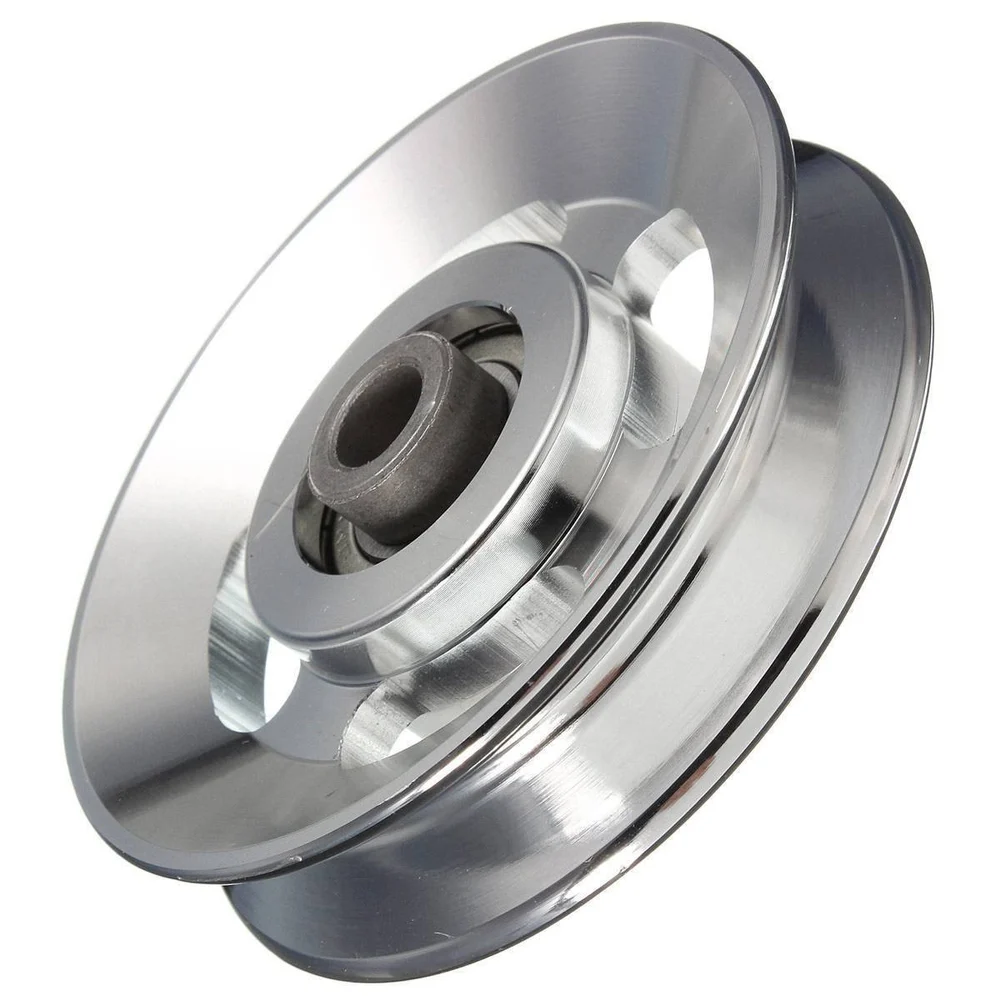

Product Description

High Performance Pulley for Belt Conveyors

BRIEF INTRODUCTION

Our company has adopted proprietary technology and equipment imported from German PWH company for the design and manufacturing of various pulleys . As a key component of the conveyor, the pulley should have high reliability. Our company’s R&D center has improved the pulley structure, reduced structural stress, and increased the lifespan and reliability of the pulley group through finite element analysis and optimization calculations. Our company’s pulley is manufactured from specialized high-end manufacturing equipment and has achieved serialized and large-scale production.

We have produced conveyor pulleys for belt width up to 2.4 m, pulley diameter up to 1.8 m, and maximum tension up to 300 tons.

PRODUCT INFORMAITON

| Product Name | Pulley |

| Adhesive Material | smooth, ordinary rubber, wear-resistant rubber, UHMW-PE, rubber ceramic, etc.. |

| Adehensive Treatment | glued or casted |

| Carrying Capacity | light, medium and heavy type |

| Connection Mode | Shafts and wheels of the medium and heavy-duty pulley are connected by expansion sleeves. |

| Pulley Pipe | made of Q235B carbon steel, with high roundness and straightness ensuring rotation balance |

| Shaft | 45 # round steel or according to your requirements; ultrasonic inspection, quenching and tempering treatment, strict control of key fit size tolerances, greatly extending service life. |

| Bearing Brands | Havalo, SKF, FAG, SNK or according to your requirements |

| Bear Seat | Integral bearing seat, partial bearing seat |

| Color | bright red paint or according to your requirements |

VARIOUS TYPES OF PULLEY ADHESIVE SURFACE

BEARING SEAT MODE

TECHNICAL SPECIFICATIONS & PARAMETERS

| Technical Parameters for Belt Conveyor Pulley | ||||||

| Belt Width (mm) | Pulley Standard Diameter without Adhesive Layer(mm) | |||||

| 650 | 200,250,320,400,500,630 | |||||

| 800 | 200,250,320,400,500,630,800,1000,1250 | |||||

| 1000 | 250,320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1200 | 250,320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1400 | 320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1600 | 400,500,630,800,1000,1250,1400,1600 | |||||

| 1800 | 250,400,500,630,800,1000,1250,1400,1600 | |||||

| 2000 | 400,500,630,800,1000,1250,1400,1600 | |||||

| Technical Parameters | ||

| 1 | Outer Circle Diameter D Deviation | 200 ≤ 1.5 400 ≤ 2.0 1000 ≤ 2.5 |

| 2 | Radial Runout of Outer Circle | D ≤ 200 ; without adhesive 0.3 ;with adhesive 0.5 200 < D ≤ 800 ; without adhesive 0.6; with adhesive 1.1 800 < D ≤ 1600 ; without adhesive 1.0; with adhesive 1.5 1600 < D ≤ 1800 ; without adhesive 1.5; with adhesive 2.0 |

| 3 | Static Balance Accuracy | G40 |

PROCESS FLOW OF PULLEY

Our company is equipped with necessary equipment for processing pulleys, such as large oil pressure machines, rolling machines, specialized pulley automatic explosive welding operators, large diameter lathes, boring machines, ultrasonic flaw detectors, static balancing devices, pressure casting machines, etc. Due to the special correction process adopted by the company, the pulley pipe skin is rounded before processing, and the pulley pipe wall is uniform after processing, thereby ensuring that the pulley has high static balance performance and high mechanical performance.

PRODUCT FEATURES

For pulleys with complex forces, large loads and used in heavy working conditions, they all adopt a cast welded structure and expansion sleeve connection. Compared with traditional drums in China, this type of drum mainly has the following characteristics :

(1) The structural parameters of the pulley are advanced and reasonable, and there is a dedicated computer calculation program to determine the shaft diameter, cylinder skin thickness, wheel amplitude plate shape and spacing, as well as the position of the circumferential weld seam set at the position where the stress is minimum and the number of cycles is minimum.

(2) The key technology of using single sided welding and double sided forming ensures the quality of the weld seam.

(3) The expansion sleeve connection is used between the drum hub and shaft, which not only solves the problem of key connection stress concentration that has been existing for many years and the technical difficulties of manufacturing and installing axial double keyways, but also achieves overall quenching and eliminates welding internal stress.

(4) The circumferential and longitudinal welds of the pulley have undergone non-destructive testing, and the casting quality of the wheel hub has undergone magnetic particle or ultrasonic testing.

(5) The total radial runout of the outer circle after roller casting is less than 1mm.

(6) All drums undergo static balance tests before leaving the factory to achieve G40 accuracy.

(7) All driving pulley and directional pulley with high stress have undergone finite element analysis to ensure that the stress and strain of the rollers meet the requirements.

Due to a series of measures taken, the pulley group produced by SK has a reasonable structure, large bearing capacity, and reliable performance. And it overcomes the problem of fatigue fracture at the welding seam of the existing pulley plate in China. The pullley (including the welding part) is guaranteed to have a rotational fatigue strength of over 108°.

WORKSHOP OF FINISHED PULLEIES

PACKAGE AND DELIVEYR

APPLICATION INDUSTRIES

CONVEYORS EPC/BOT CONTRACTING CAPABILITY

VARIOUS CONVEYOR SPARE PARTS SUPPLY

AERIAL VIEW OF OUR FACTORY

INTELLIGENT PRODUCTION & TESTING

CERTIFICATES & HORNORS

BRANCHES & OFFICES

TEAM BUILDING

LONG-TERM STRATEGIC COOPEATORS

MAIN CUSTOMERS

CUSTOMERS VISITS

DOMESTIC & OVERSEAS EXHIBITIONS

SINGING CEREMONY

GLOBAL BUSINESS NETWORK

B /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Kk |

| Manufacturing Process: | Forging, Casting |

| Material: | Carbon Steel |

| Surface Treatment: | Smooth, Rubber or Ceramics |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Port, Dock, Energy, Cement, Metallurgy, Steel |

| Samples: |

US$ 7/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What maintenance practices should be followed to ensure the longevity of steel pulleys?

To ensure the longevity and optimal performance of steel pulleys, several maintenance practices should be followed. Here’s a detailed explanation:

1. Regular Inspection:

Perform regular visual inspections of the steel pulleys to identify any signs of wear, damage, or misalignment. Look for cracks, excessive wear on the grooves, or any abnormalities that may affect the pulley’s performance. Promptly address any issues discovered during inspections.

2. Lubrication:

Proper lubrication is essential for reducing friction, preventing excessive wear, and ensuring smooth operation of the pulleys. Follow the manufacturer’s guidelines and apply appropriate lubricants to the bearings and moving parts of the pulleys at recommended intervals.

3. Belt or Cable Tension:

Maintain proper tension in belts, ropes, or cables connected to the pulleys. Incorrect tension can lead to slippage, increased wear, and reduced power transmission efficiency. Refer to the manufacturer’s recommendations or industry standards for the appropriate tension levels.

4. Cleaning:

Regularly clean the steel pulleys to remove dirt, debris, or contaminants that can accumulate on the surfaces. Use appropriate cleaning methods and avoid using abrasive materials that may damage the pulley. Keeping the pulleys clean helps prevent premature wear and ensures smooth operation.

5. Alignment:

Proper alignment of the pulleys is crucial for their longevity. Misaligned pulleys can cause excessive stress, vibration, and accelerated wear. Regularly check the alignment and make adjustments as necessary to ensure that the pulleys are properly aligned with the drive system.

6. Balancing:

If the pulleys are dynamically balanced, ensure that the balance is maintained. Imbalances can lead to vibration, increased stress, and premature failure. If a pulley shows signs of imbalance, consult a professional for corrective measures.

7. Environmental Considerations:

Take into account the environmental conditions in which the pulleys operate. If the environment is corrosive or exposes the pulleys to contaminants, consider using corrosion-resistant materials or implementing protective measures to prevent damage.

8. Record Keeping:

Maintain records of maintenance activities, including inspections, lubrication schedules, and any repairs or replacements. This documentation helps track the maintenance history of the pulleys and informs future maintenance decisions.

9. Professional Assistance:

If you are unsure about any maintenance aspect or encounter significant issues, consult with a qualified professional or the manufacturer for guidance and assistance.

By following these maintenance practices, you can prolong the lifespan of steel pulleys, ensure their reliable operation, and minimize the risk of unexpected failures or downtime.

Are there safety considerations when using steel pulleys for heavy lifting or rigging?

Yes, there are several safety considerations when using steel pulleys for heavy lifting or rigging. Here’s a detailed explanation:

1. Working Load Limits:

It is crucial to determine and adhere to the working load limits (WLL) specified by the manufacturer for the steel pulleys. Exceeding the recommended load limits can result in pulley failure, compromising safety. The WLL accounts for factors such as load capacity, material strength, and design characteristics of the pulleys.

2. Inspection and Maintenance:

Regular inspection and maintenance of steel pulleys are essential to ensure safe operation. Inspections should include checking for signs of wear, damage, or deformities in the pulley components, such as cracks, corrosion, or excessive wear on the grooves. Any pulleys showing signs of damage should be taken out of service and replaced promptly.

3. Proper Mounting and Alignment:

Steel pulleys should be mounted and aligned correctly to prevent misalignment or excessive lateral forces on the pulley components. Misalignment can cause increased wear, reduced efficiency, and premature failure. It is important to follow the manufacturer’s instructions for proper installation and alignment to maintain safe and reliable operation.

4. Selection of Appropriate Pulleys:

The selection of the appropriate steel pulleys for heavy lifting or rigging applications is critical for safety. Factors such as load capacity, pulley size, bearing type, and compatibility with the lifting equipment should be carefully considered. Using pulleys that are not specifically designed for heavy lifting can lead to structural failures, accidents, or equipment damage.

5. Proper Use of Rigging Equipment:

When using steel pulleys for heavy lifting or rigging, it is important to ensure the proper use of rigging equipment, such as slings, ropes, or cables. Rigging equipment should be inspected regularly for wear, damage, or deterioration. Correct rigging techniques, including proper load distribution and securing methods, should be followed to prevent accidents or load instability.

6. Training and Competence:

Operators and rigging personnel should receive adequate training and possess the necessary competence to handle steel pulleys for heavy lifting or rigging operations safely. Training should cover topics such as proper equipment usage, load calculations, inspection procedures, and safe handling practices. Competent personnel can make informed decisions, detect potential hazards, and mitigate risks associated with steel pulley operations.

7. Compliance with Regulations:

Adherence to applicable regulations, standards, and industry best practices is essential for safe use of steel pulleys for heavy lifting or rigging. Regulations may vary depending on the jurisdiction and industry. It is important to stay updated with relevant regulations and ensure compliance to maintain a safe working environment.

It is crucial to prioritize safety when using steel pulleys for heavy lifting or rigging. Consulting with qualified engineers or rigging specialists, following manufacturer guidelines, conducting regular inspections, and providing adequate training can help mitigate risks and ensure the safe and efficient use of steel pulleys in heavy lifting and rigging applications.

How does the design of steel pulleys impact their load-bearing capacity and efficiency?

The design of steel pulleys plays a crucial role in determining their load-bearing capacity and efficiency. Here’s a detailed explanation:

1. Diameter and Width:

The diameter and width of a steel pulley directly impact its load-bearing capacity. Larger diameter pulleys distribute the load over a greater surface area, reducing stress and increasing the pulley’s capacity to handle heavier loads. Similarly, wider pulleys provide more contact area for the belt, rope, or cable, allowing for improved load distribution and increased load-bearing capacity.

2. Groove Profile:

The groove profile of a steel pulley affects its efficiency and load-bearing capacity. Different groove profiles, such as V-shaped, U-shaped, or flat, are designed to accommodate specific types of belts, ropes, or cables. The groove profile should match the corresponding belt or cable to ensure proper engagement, minimize slippage, and maximize the load-carrying capability of the pulley.

3. Flanges and Guards:

Pulleys can be designed with flanges or guards on the sides to prevent the belt, rope, or cable from slipping off during operation. Flanges provide guidance and keep the material being conveyed centered on the pulley, enhancing the load-bearing capacity and efficiency. Guards also protect the belt or cable from external elements, reducing the risk of damage and improving overall performance.

4. Bearing Type and Arrangement:

The type and arrangement of bearings in a steel pulley significantly impact its load-bearing capacity and efficiency. High-quality bearings, such as deep groove ball bearings or roller bearings, reduce friction and enable smooth rotation, enhancing the efficiency of power transmission. Proper bearing arrangement, such as using multiple bearings or incorporating bearing supports, ensures optimal load distribution and improves the pulley’s ability to handle higher loads.

5. Material Selection:

The choice of steel material for pulley construction affects both load-bearing capacity and efficiency. High-strength steel alloys or heat-treated steels provide greater load-carrying capacity and resistance to wear or deformation. The material should be selected based on the specific application requirements, considering factors such as load magnitude, operating conditions, and environmental factors.

6. Balanced Design:

A well-balanced design is essential for efficient and reliable operation. Imbalances in the pulley design can cause vibration, increased wear, and reduced load-bearing capacity. Proper balancing techniques, such as counterweights or precision machining, ensure smooth rotation, minimize stress on the pulley and associated components, and optimize load-bearing capacity.

7. Alignment and Installation:

The proper alignment and installation of steel pulleys are critical for their load-bearing capacity and efficiency. Pulleys should be aligned accurately with the drive system to prevent misalignment-induced stress and premature wear. Correct installation techniques, such as applying proper tension to belts or cables, ensure optimal power transmission and efficient load-bearing performance.

In summary, the design of steel pulleys directly impacts their load-bearing capacity and efficiency through factors such as diameter and width, groove profile, flanges and guards, bearing type and arrangement, material selection, balanced design, and proper alignment and installation. By considering these design aspects, manufacturers can optimize the performance and capabilities of steel pulleys, enabling them to handle higher loads, minimize energy losses, and operate with greater efficiency.

editor by CX

2024-04-23