Product Description

Product Description

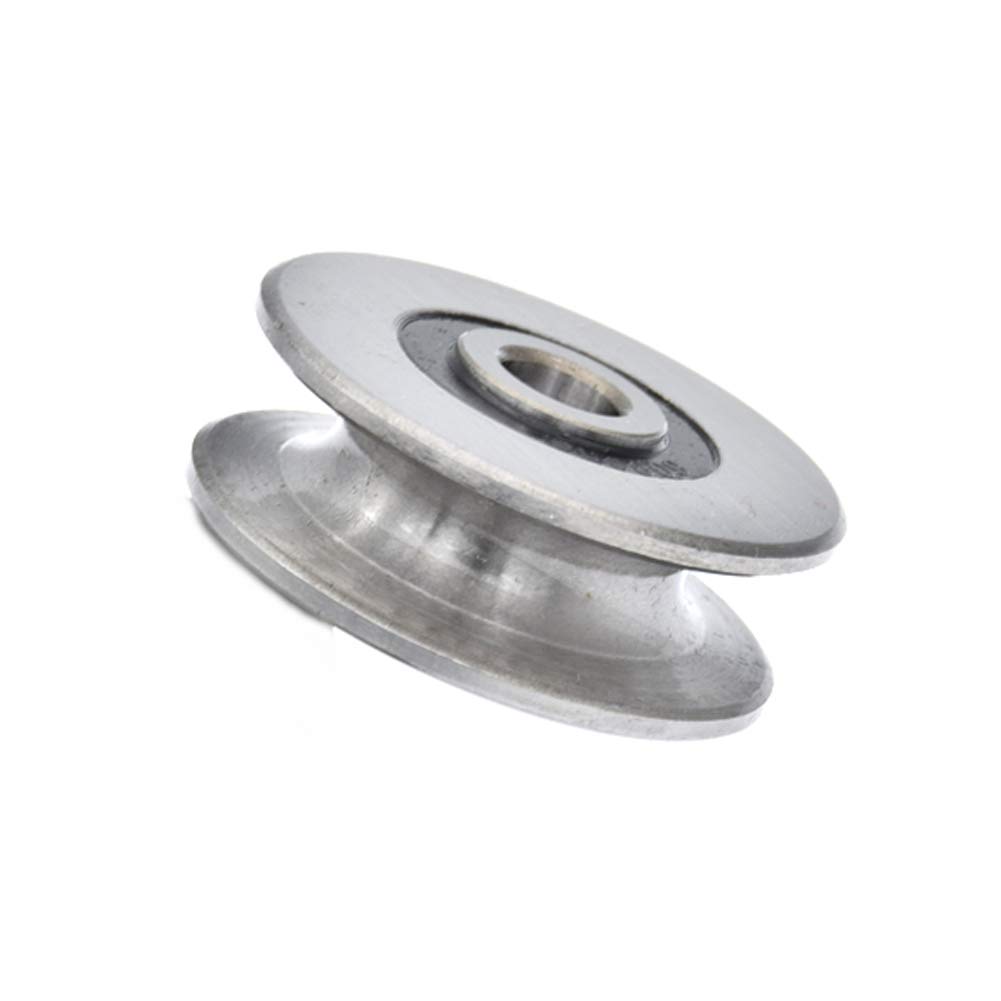

A timing pulley is a wheel component used for transmission, which is often used in combination with a timing belt or a synchronous chain to achieve precision synchronous transmission. The timing pulley usually consists of 2 parts: the wheel flange and the hub. The wheel flange usually has a toothed structure that can be combined with a timing belt or chain to achieve a precise synchronous transmission effect. Synchronous wheels can be divided into 2 categories: grinding gear synchronous wheels and forged tooth synchronous wheels.

Product Parameters

| product | Metal Iron Timing Belt Pulley/ Synchronous Belt Pulley for Packaging machine |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2: What are the common types of tooth profiles for synchronous belt pulleys?

A: The most common tooth profiles for synchronous belt pulleys are the trapezoidal (or T-type) and curvilinear (or HTD-type) profiles. The tooth profile determines the pitch diameter, which affects the overall ratio of the gear drive.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type D |

| Manufacturing Process: | Forging |

| Material: | Stainless Steel |

| Surface Treatment: | Electroplating |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the role of steel pulleys in the mining and construction industries?

Steel pulleys play a crucial role in the mining and construction industries, contributing to the efficient and reliable operation of various equipment and systems. Here’s a detailed explanation:

1. Conveyor Systems:

In both mining and construction, conveyor systems are extensively used for the transportation of bulk materials, such as ores, aggregates, and construction materials. Steel pulleys are integral components of conveyor systems, providing support, guidance, and tensioning for conveyor belts. They help facilitate the smooth movement of materials, ensuring efficient material handling and reducing manual labor requirements.

2. Hoisting and Lifting Equipment:

In mining and construction, hoisting and lifting equipment, such as cranes, winches, and elevators, are essential for lifting heavy loads and transporting them vertically or horizontally. Steel pulleys are critical components in these systems, enabling the transmission of power and torque to lift and move heavy loads safely and efficiently. They are used in conjunction with wire ropes, cables, or chains to create mechanical advantage and control the lifting process.

3. Drilling and Excavation Machinery:

In mining and construction, drilling and excavation machinery, such as drilling rigs, tunnel boring machines, and excavators, are employed for digging, drilling, and creating openings in the ground. Steel pulleys contribute to the operation of these machines by facilitating the movement and control of cables, ropes, or belts that drive the drilling or excavation mechanisms. They help transmit power, control speed, and guide the movement of the drilling or excavation components.

4. Crushing and Screening Equipment:

In mining and construction projects, crushing and screening equipment is used to process raw materials into desired sizes and shapes. Steel pulleys are utilized in crushers, screens, and other processing machinery to drive the rotational motion of belts or pulley systems. They help maintain proper tension, control the speed of the components, and ensure efficient material processing.

5. Power Transmission Systems:

Steel pulleys are integral to power transmission systems in mining and construction equipment. They are used in conjunction with belts, chains, or gears to transmit power from engines or motors to various components, such as pumps, fans, or compressors. Steel pulleys enable precise control over speed, torque, and power distribution, ensuring efficient and reliable operation of the equipment.

6. Tensioning and Tracking:

In mining and construction applications, belts, ropes, or cables connected to various equipment and systems require proper tensioning and tracking to ensure reliable performance. Steel pulleys with tensioning devices, such as take-up systems or adjustable pulleys, help maintain the desired tension and alignment of the belts or cables. This promotes optimal operation, reduces wear, and minimizes the risk of slippage or misalignment.

7. Durability and Reliability:

Mining and construction environments are often demanding, with harsh conditions, heavy loads, and intensive operations. Steel pulleys are chosen for their durability and reliability in such challenging environments. They are designed to withstand high loads, resist wear, and operate consistently under demanding conditions, contributing to the overall reliability and longevity of mining and construction equipment.

In summary, steel pulleys play a vital role in the mining and construction industries by contributing to the efficient operation of conveyor systems, hoisting and lifting equipment, drilling and excavation machinery, crushing and screening equipment, power transmission systems, and tensioning/tracking applications. Their durability, reliability, and ability to handle heavy loads make them indispensable components in these industries.

How do steel pulleys compare to other materials, such as plastic or aluminum, in various scenarios?

Steel pulleys, plastic pulleys, and aluminum pulleys each have their own advantages and considerations in different scenarios. Here’s a detailed comparison:

1. Strength and Durability:

Steel pulleys generally offer higher strength and durability compared to plastic or aluminum pulleys. Steel has excellent load-bearing capacity and can withstand heavy loads and high forces without deformation. Plastic pulleys are lightweight but may have lower strength and may not be suitable for heavy-duty applications. Aluminum pulleys offer a good balance between strength and weight, but they may not be as durable as steel pulleys in certain demanding scenarios.

2. Corrosion Resistance:

Steel pulleys often exhibit better corrosion resistance compared to aluminum pulleys, especially when made from stainless steel or galvanized steel. Plastic pulleys are inherently corrosion-resistant, which makes them suitable for applications where exposure to moisture or chemicals is a concern. Aluminum pulleys may require additional protective coatings or treatments to enhance their corrosion resistance.

3. Weight:

Plastic and aluminum pulleys are generally lighter than steel pulleys. In applications where weight reduction is critical, such as in industries like aerospace or automotive, plastic or aluminum pulleys may be preferred. However, it is important to consider the load requirements and select a material that can handle the anticipated forces without compromising safety or performance.

4. Friction and Wear:

Steel pulleys typically have smoother surfaces and better wear resistance compared to plastic pulleys. The smooth surfaces of steel pulleys reduce friction and wear on the belt or rope, contributing to improved efficiency and longevity. Plastic pulleys may have higher friction coefficients and may require additional lubrication or specialized coatings to reduce wear. Aluminum pulleys can have good wear resistance but may not be as durable as steel pulleys in high-load or abrasive environments.

5. Temperature Resistance:

Steel pulleys generally have better temperature resistance compared to plastic pulleys. Steel can withstand higher temperatures without deformation or loss of strength. Plastic pulleys may have limitations in high-temperature applications due to their lower melting points. Aluminum pulleys have good heat dissipation properties but may experience thermal expansion.

6. Cost:

Steel pulleys are often more cost-effective compared to aluminum pulleys, especially for larger or heavy-duty applications. Plastic pulleys can be cost-effective for certain low-load or non-critical applications. Aluminum pulleys are generally more expensive than steel pulleys but offer advantages in terms of weight savings and specific applications where their properties are advantageous.

7. Noise and Vibration:

Steel pulleys tend to produce less noise and vibration compared to plastic pulleys. Steel’s higher density and rigidity help dampen vibrations and reduce noise levels. Plastic pulleys may generate more noise and vibration, particularly at high speeds or under heavy loads. Aluminum pulleys can offer good vibration damping properties but may not be as effective as steel in certain scenarios.

In summary, the choice between steel, plastic, or aluminum pulleys depends on the specific requirements of the application. Steel pulleys offer superior strength, durability, corrosion resistance, and wear resistance, making them suitable for heavy-duty and demanding scenarios. Plastic pulleys are lightweight, corrosion-resistant, and cost-effective for certain low-load applications. Aluminum pulleys provide a balance between strength and weight, making them advantageous in weight-sensitive applications. Consideration should be given to factors such as load requirements, environmental conditions, temperature, cost, and performance characteristics to determine the most suitable pulley material for a given scenario.

What are steel pulleys, and how are they used in various applications?

Steel pulleys are mechanical devices made primarily from steel that are used to guide or redirect ropes, cables, or belts in various applications. Here’s a detailed explanation:

1. Construction and Engineering:

In construction and engineering, steel pulleys are commonly used in hoisting and lifting systems. They provide a stable and durable mechanism for raising and lowering heavy loads, such as construction materials, equipment, or machinery. Steel pulleys used in these applications are designed to withstand high loads and harsh operating conditions.

2. Industrial Machinery and Manufacturing:

Steel pulleys find extensive use in industrial machinery and manufacturing processes. They are employed in conveyor systems to move materials or products along assembly lines. Steel pulleys with different diameters and groove configurations are used to facilitate belt or chain movement, ensuring efficient and reliable material handling.

3. Automotive and Transportation:

In the automotive and transportation industries, steel pulleys are utilized in various applications. They are commonly found in engines as part of the accessory drive system, where they drive components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure smooth operation and reliable power transmission in these critical systems.

4. Gym and Fitness Equipment:

Steel pulleys are integral components of gym and fitness equipment, such as cable machines or weightlifting systems. They enable smooth and controlled movement of cables or belts, allowing users to perform exercises safely and effectively. Steel pulleys used in fitness equipment are designed to withstand repetitive loads and provide long-lasting performance.

5. Material Handling and Rigging:

Steel pulleys play a crucial role in material handling and rigging applications. They are used in systems such as cranes, winches, and lifting equipment to redirect cables or ropes, enabling the lifting and movement of heavy objects. Steel pulleys in these applications are engineered to handle substantial loads and ensure safe and efficient material handling.

6. Entertainment and Theatrical Rigging:

In the entertainment industry, steel pulleys are utilized in theatrical rigging systems. They are employed to control the movement of stage components, lighting fixtures, curtains, and other theatrical elements. Steel pulleys in this context must meet stringent safety standards and provide precise positioning and smooth operation.

7. Recreational Activities:

Steel pulleys are also utilized in various recreational activities. For example, in zip line courses or rope courses, steel pulleys are used to guide participants along the course safely. In rock climbing, steel pulleys may be employed as part of hauling systems or belay devices. These pulleys are designed to withstand high forces and ensure reliable performance in adventurous settings.

Steel pulleys offer strength, durability, and reliability in a wide range of applications. Their ability to handle heavy loads, provide smooth operation, and withstand harsh conditions makes them indispensable in industries such as construction, manufacturing, automotive, fitness, entertainment, and recreational activities.

editor by CX

2024-04-25