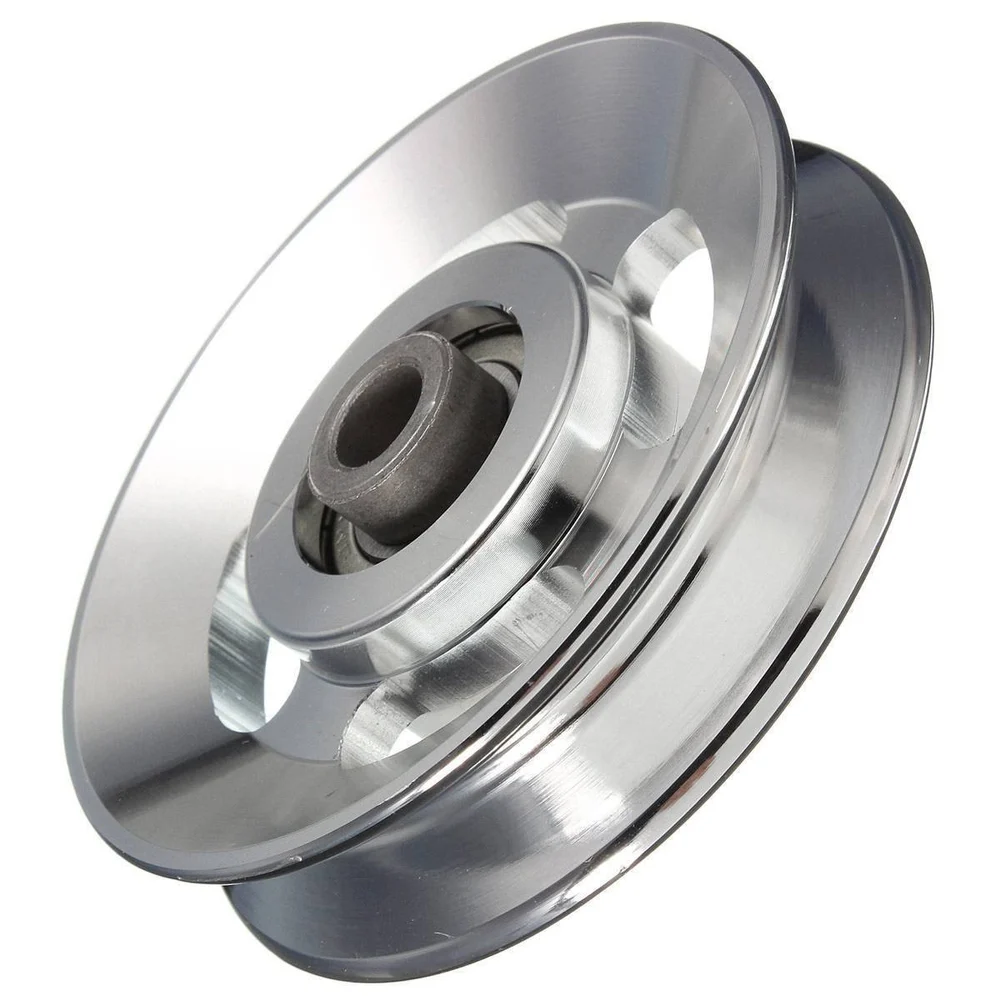

Product Description

Trolley Crane Steel Welding Pulley for Gravity machinery

Product Description

Container crane pulley block,

With high bearing capacity, high wear resistance and long service life

Sheave features:

1) Material: Q235B, Q345B, 35#, 45#, 60#, SSW-QR1, S45C

2) Groove surface quench: HRC45-55

3) Groove surface quench depth: 2mm-2.5mm

4) groove MT after heat treatment and welding line UT and MT

4) Max processing diameter: 2, 000mm

5) Short production cycle

It is used for crane equipment, port equipment, oil drilling rig and so on.

| Code | Wire rope diameter(mm) | Main dimension(mm) | Weight for reference(kg) | ||||||

| D | D1 | R | b | W | D2 | B | |||

| BX1282 | 10-14 | 400 | 445 | 7 | 37 | 28 | 60 | 66 | 20 |

| BX2282 | >14-19 | 500 | 560 | 10 | 50 | 38 | 85 | 78 | 34 |

| BX3282 | >19-23.5 | 630 | 701 | 12 | 60 | 46 | 100 | 94 | 60 |

| BX4282 | >23.5-30 | 800 | 890 | 15 | 73 | 57 | 140 | 110 | 108 |

| BX5282 | >23.5-30 | 1000 | 1112 | 19 | 92 | 72 | 170 | 136 | 187 |

| BX6282 | >30-37 | 1120 | 1246 | 22 | 104 | 82 | 170 | 136 | 239 |

| BX7282 | >43-50 | 1400 | 1552 | 26 | 123 | 98 | 200 | 154 | 454 |

| BX8282 | >50-58 | 1600 | 1772 | 29 | 135 | 110 | 200 | 154 | 594 |

Detailed Photos

Our Advantages

Application

| Other Products |

Company Profile

Factory introduction

HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. is a high-tech enterprise registered in HangZhou City of ZheJiang Province, which is mainly engaged in the design and manufacture of spare parts for metallurgy equipment, hoisting machinery, oil drilling rigs, and heavy decelerator boxes.

Our company boasts a professional team who is full of vitality, with high efficiency, and industry minded. Our R&D technicians are highly skilled with rich experience, and possess strong design and development capabilities. There are 2 experts in our company who enjoy the state special allowance. We have carried out broad cooperation with renowned factories and design institutes both at home and abroad.

With advanced design, outstanding manufacturing crafts and vigorous management, the whole manufacturing process of our company is conducted by strictly implementing strict quality management system. Our products are widely used by a great number of steel plants in China and exported overseas, where they have received high praise from our customers.

By following the enterprise philosophy of innovation, quality and creating value for the clients, our company is constantly bringing in advanced technologies from home and abroad. We are committed to taking the enhancement of product quality, safety and reliability as our responsibility and striving for providing high quality products and perfect services to the clients.

HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. Warmly welcomes you to be our distinguished clients and friends.

Customer Visiting

Certifications

Packaging & Shipping

| Sever&FAQ |

Our Service:

If you are interested in any of our products, please contact me freely! Warmly Welcomed your visit to our factory in China, OEM service will be ok.

FAQ:

Q: What information should I provide if I want to order the products?

1) Product information: Quantity, specification

2) Delivery time required.

3) Shipping information: Company name, address, phone number, destination seaport/air port.

4) Forwarder’s contact details if there is any in China.

Q: How about your payment terms?

A: 30% -50%deposit, with the balance before delivery, we accept T/T and L/C at sight.

Q: Can I use our own logo?

A: Yes, we can produce by using your own logo if you need.

Q: How about sample & MOQ policy?

A: Welcome sample order. MOQ can be 1 set.

Q: What is your lead time for your goods?

A: Normally 30 days after confirmed order,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Condition: | New |

| Maximum Lifting Height: | 50-100m |

| Maximum Lifting Weight: | >10t |

| Installation: | Assembled |

| Moving Type: | Wheel |

| Customization: |

Available

| Customized Request |

|---|

How do steel pulleys enhance the precision and control of various mechanical operations?

Steel pulleys play a crucial role in enhancing the precision and control of various mechanical operations. Here’s a detailed explanation:

1. Power Transmission:

Steel pulleys are used in conjunction with belts, ropes, or cables to transmit power from one component to another. By utilizing the mechanical advantage of pulleys, it becomes possible to control and regulate the speed, torque, and direction of the transmitted power. This enables precise control over the mechanical operation and facilitates the achievement of desired outcomes.

2. Mechanical Advantage:

Steel pulleys leverage the concept of mechanical advantage to enhance precision and control. The ratio of the diameters or number of grooves in the pulley system determines the mechanical advantage achieved. By selecting the appropriate pulley size and configuration, mechanical operations can be fine-tuned to optimize performance and control variables such as speed, force, and motion.

3. Speed Control:

Steel pulleys, especially those with variable speed capabilities, enable precise speed control in mechanical operations. By adjusting the effective diameter of the pulley, the rotational speed of the driven component can be modified. This is particularly useful in applications where speed regulation is critical, such as in machinery used for manufacturing, processing, or automation.

4. Torque Transfer:

Pulleys facilitate the transfer of torque from the driving component to the driven component. The size and configuration of the pulleys, along with the tension in the connecting belt or cable, determine the torque transmitted. By carefully selecting the pulley system, the torque can be controlled and distributed as required, ensuring precise and reliable torque transfer for mechanical operations.

5. Synchronization:

In certain applications, precise synchronization of mechanical operations is essential. Steel pulleys, when used in conjunction with timing belts or chains, enable accurate synchronization between multiple components. This is commonly seen in applications such as conveyor systems, robotic arms, or printing presses, where coordinated motion is critical for proper functioning and precision.

6. Control over Mechanical Loads:

Steel pulleys provide control over mechanical loads by managing tension and distributing forces. By properly tensioning the belts, ropes, or cables, the pulleys ensure that the load is evenly distributed across the system, minimizing the risk of slippage, excessive wear, or component failures. This control over mechanical loads enhances the precision and reliability of mechanical operations.

7. Reducing Vibration and Noise:

Steel pulleys, when properly designed and balanced, help reduce vibration and noise generated during mechanical operations. Vibration and noise can negatively impact precision and control, leading to suboptimal performance or discomfort. By incorporating features such as dynamic balancing and precision machining, steel pulleys minimize vibrations and contribute to smoother, quieter mechanical operations.

In summary, steel pulleys enhance the precision and control of various mechanical operations by facilitating power transmission, leveraging mechanical advantage, enabling speed control, ensuring torque transfer, enabling synchronization, managing mechanical loads, and reducing vibration and noise. Their versatility and ability to fine-tune mechanical systems make them invaluable components in a wide range of industries and applications.

How does the quality and precision of steel pulley components affect their performance?

The quality and precision of steel pulley components have a significant impact on their performance. Here’s a detailed explanation:

1. Load Capacity:

High-quality steel pulley components are engineered to withstand specific load capacities. The use of high-grade steel with appropriate strength and hardness ensures that the pulley can handle the intended loads without deformation or failure. Precision in manufacturing processes ensures consistent performance and reliable load-bearing capabilities.

2. Durability and Longevity:

Precision manufacturing techniques and the use of high-quality materials enhance the durability and longevity of steel pulley components. Components manufactured to precise specifications are less prone to wear, fatigue, and premature failure. High-quality steel with proper heat treatment and surface finishes improves resistance to corrosion, abrasion, and other forms of degradation, extending the lifespan of the pulley.

3. Smooth Operation:

Precision in the design and manufacturing of steel pulley components contributes to smooth operation. Well-machined components ensure proper alignment, balance, and concentricity, reducing friction and minimizing vibrations. Smooth operation enhances efficiency, reduces power losses, and extends the lifespan of associated equipment, such as belts, bearings, and drives.

4. Reduction of Noise and Vibration:

Poorly manufactured or low-quality steel pulley components can generate excessive noise and vibration during operation. Precision manufacturing techniques, such as accurate machining and balancing, help minimize vibrations and noise levels. This improves operator comfort, reduces equipment fatigue, and promotes a safer and more productive work environment.

5. Belt Tracking and Tensioning:

Precision in the design and manufacture of steel pulley components plays a crucial role in belt tracking and tensioning. Components with accurate dimensions and smooth surfaces ensure proper alignment and contact with the belt, facilitating efficient power transmission and minimizing belt slippage. Precise tensioning mechanisms and adjustments allow for optimal belt tension, reducing wear and extending belt life.

6. Compatibility and Interchangeability:

High-quality steel pulley components are designed and manufactured to precise standards, ensuring compatibility and interchangeability with other components and systems. This allows for easier installation, replacement, and maintenance. Components that meet standardized dimensions and tolerances can be readily sourced and integrated into existing equipment or systems.

7. Safety and Reliability:

The quality and precision of steel pulley components directly influence the safety and reliability of the overall system. Components manufactured to high standards minimize the risk of sudden failures, malfunctions, or accidents. Reliable performance of pulley components enhances the overall reliability of equipment and reduces the likelihood of costly downtime or maintenance.

In summary, the quality and precision of steel pulley components are critical factors in determining their performance. High-quality components offer superior load capacity, durability, smooth operation, reduced noise and vibration, optimized belt tracking and tensioning, compatibility and interchangeability, as well as enhanced safety and reliability. It is essential to source steel pulley components from reputable manufacturers that adhere to stringent quality control measures and employ precision manufacturing techniques.

How does the design of steel pulleys impact their load-bearing capacity and efficiency?

The design of steel pulleys plays a crucial role in determining their load-bearing capacity and efficiency. Here’s a detailed explanation:

1. Diameter and Width:

The diameter and width of a steel pulley directly impact its load-bearing capacity. Larger diameter pulleys distribute the load over a greater surface area, reducing stress and increasing the pulley’s capacity to handle heavier loads. Similarly, wider pulleys provide more contact area for the belt, rope, or cable, allowing for improved load distribution and increased load-bearing capacity.

2. Groove Profile:

The groove profile of a steel pulley affects its efficiency and load-bearing capacity. Different groove profiles, such as V-shaped, U-shaped, or flat, are designed to accommodate specific types of belts, ropes, or cables. The groove profile should match the corresponding belt or cable to ensure proper engagement, minimize slippage, and maximize the load-carrying capability of the pulley.

3. Flanges and Guards:

Pulleys can be designed with flanges or guards on the sides to prevent the belt, rope, or cable from slipping off during operation. Flanges provide guidance and keep the material being conveyed centered on the pulley, enhancing the load-bearing capacity and efficiency. Guards also protect the belt or cable from external elements, reducing the risk of damage and improving overall performance.

4. Bearing Type and Arrangement:

The type and arrangement of bearings in a steel pulley significantly impact its load-bearing capacity and efficiency. High-quality bearings, such as deep groove ball bearings or roller bearings, reduce friction and enable smooth rotation, enhancing the efficiency of power transmission. Proper bearing arrangement, such as using multiple bearings or incorporating bearing supports, ensures optimal load distribution and improves the pulley’s ability to handle higher loads.

5. Material Selection:

The choice of steel material for pulley construction affects both load-bearing capacity and efficiency. High-strength steel alloys or heat-treated steels provide greater load-carrying capacity and resistance to wear or deformation. The material should be selected based on the specific application requirements, considering factors such as load magnitude, operating conditions, and environmental factors.

6. Balanced Design:

A well-balanced design is essential for efficient and reliable operation. Imbalances in the pulley design can cause vibration, increased wear, and reduced load-bearing capacity. Proper balancing techniques, such as counterweights or precision machining, ensure smooth rotation, minimize stress on the pulley and associated components, and optimize load-bearing capacity.

7. Alignment and Installation:

The proper alignment and installation of steel pulleys are critical for their load-bearing capacity and efficiency. Pulleys should be aligned accurately with the drive system to prevent misalignment-induced stress and premature wear. Correct installation techniques, such as applying proper tension to belts or cables, ensure optimal power transmission and efficient load-bearing performance.

In summary, the design of steel pulleys directly impacts their load-bearing capacity and efficiency through factors such as diameter and width, groove profile, flanges and guards, bearing type and arrangement, material selection, balanced design, and proper alignment and installation. By considering these design aspects, manufacturers can optimize the performance and capabilities of steel pulleys, enabling them to handle higher loads, minimize energy losses, and operate with greater efficiency.

editor by CX

2024-05-07