Product Description

Company Profile

HangZhou Doerbee International Trade Co. , Ltd. , located in HangZhou hi-tech Development Zone, ZheJiang Province, the company’s main auto parts, mechanical and electrical supplies. Our company has established long-term and stable cooperative relations with many auto parts factories in ZHangZhoug and ZheJiang provinces. We value credit, abide by contracts, guarantee product quality, win the trust of our customers, and make every effort to follow their needs, continuous product innovation and service improvement. OEM, sample can be customized. We will gradually improve the product types and details, if you have non-standard products need us to help you find Chinese manufacturers, please contact us, send samples, we will be your most responsible and professional partner in China. Looking CHINAMFG to working with you.

Every month, we will go back and forth to each auto parts manufacturer to find and compare all kinds of high quality and low price products for you. If you have samples, but can not confirm the model or name, you can also send samples to us, we will try our best to find out the sample manufacturers in China, compare the quality for you, and provide quotation. We represent all kinds of auto parts and mechanical and electrical products, in the future we will continue to improve the product category, please pay attention to us, any need, please feel free to contact us. At present, there are more than 3

Q1. How to buy?

A1:Large quantity for more discount : Inquiry → Quotation → Price resonable → Check with specification → Proforma Invoice sent → Payment made → Product shipment → Customer

Q2. What is your terms of payment?

A2:T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A3:Generally, it will take 20 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A4:Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A5:We can supply the sample if we have ready parts in stock, but the customers have to pay the sample and courier cost.

Q6. Do you test all your goods before delivery?

A6:Yes, We will take 100% testing and photos before delivery, and keep communication with you at any time.

Q7: How do you make our business long-term and good relationship?

A7:We are not only partners, but also friends. We will try our best to provide you with the most cost-effective products. If you have any goods that are difficult to purchase, we will try our best to find them in China. We will become your most trusted buyers in China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 100000 Km |

|---|---|

| Warranty: | 2 Years |

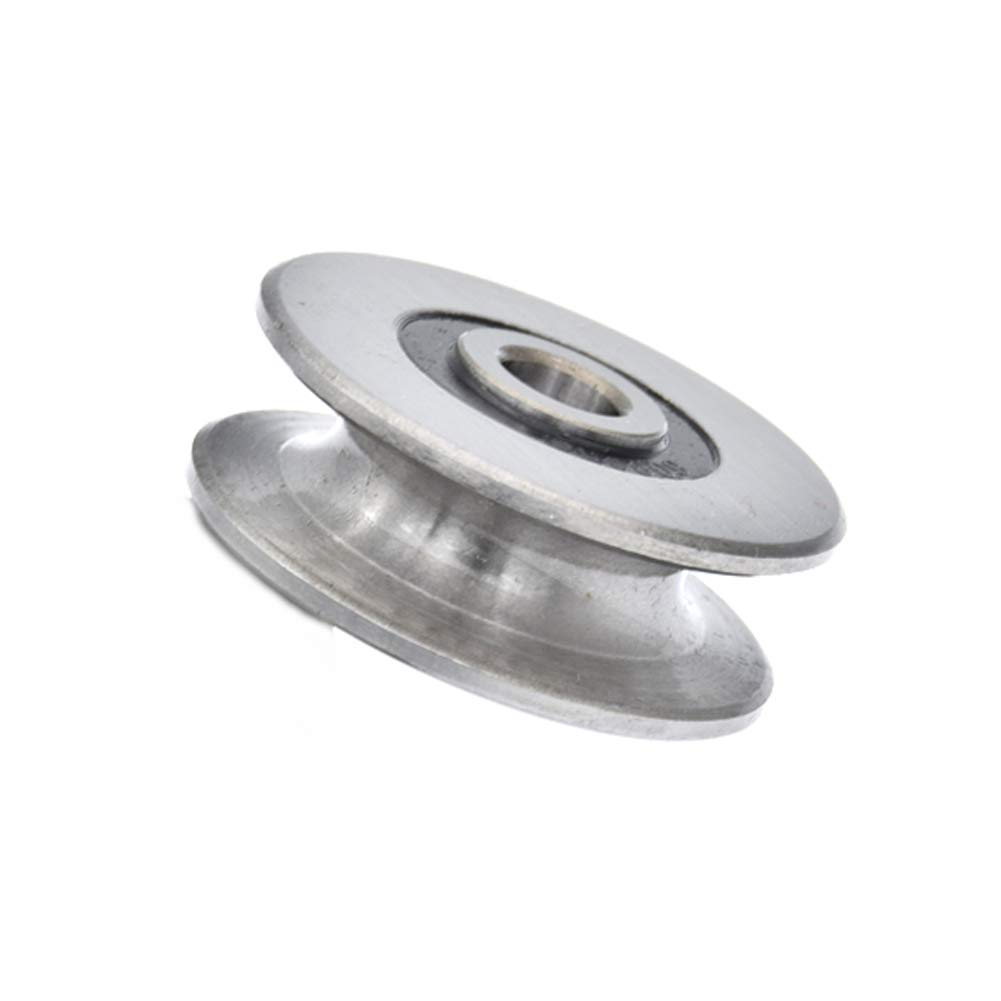

| Type: | Auto Clutch Bearing |

| Material: | Carbon Steel |

| Tolerance: | P5 |

| Certification: | TS16949 |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different sizes and configurations of steel pulleys available for specific applications?

Yes, there are different sizes and configurations of steel pulleys available to cater to specific applications. Here’s a detailed explanation:

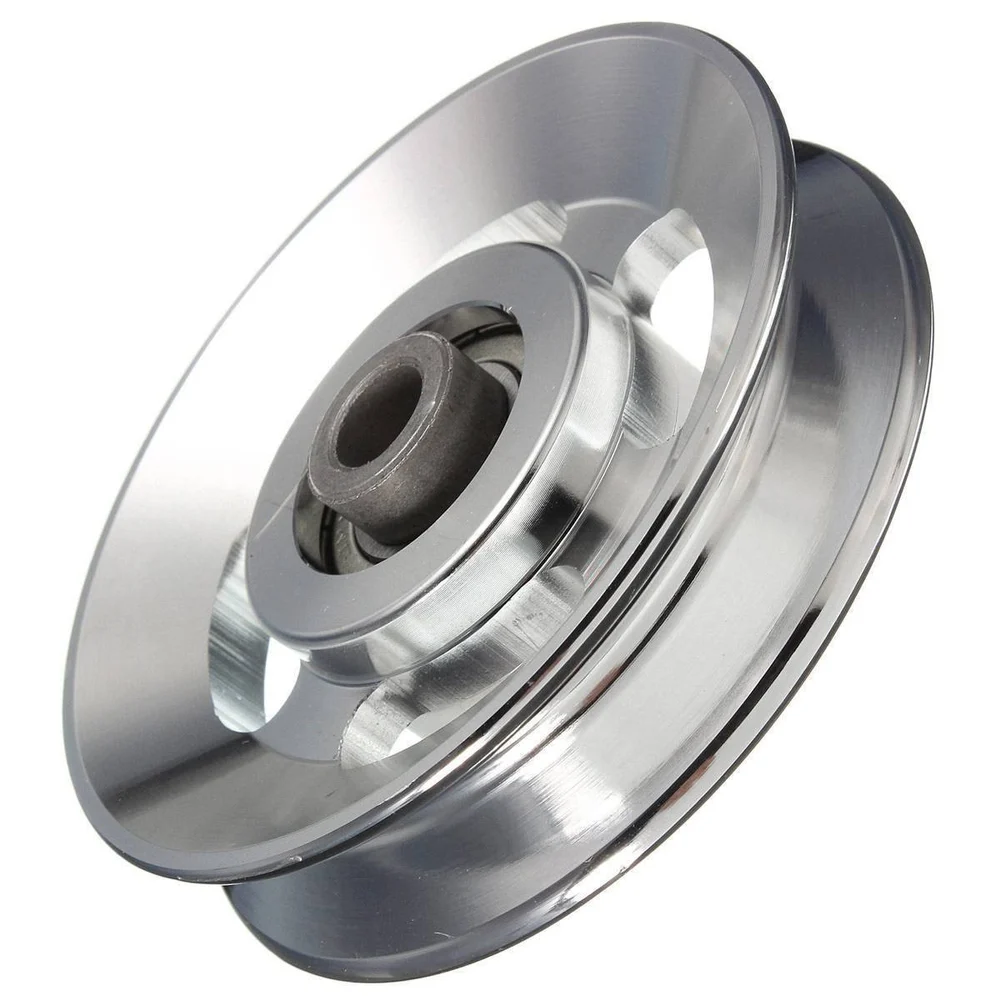

1. Size Variations:

Steel pulleys are manufactured in various sizes to accommodate different load requirements and belt or cable dimensions. Pulley size is typically defined by its diameter, which can range from small pulleys used in miniature applications to large pulleys used in heavy-duty industrial systems. By offering a range of sizes, manufacturers ensure that there is a suitable pulley size for specific application needs.

2. Configuration Options:

Steel pulleys come in different configurations based on the specific application requirements. Some common configurations include:

- Flat Pulleys: These pulleys have a flat surface and are commonly used with flat belts.

- V-Belt Pulleys: These pulleys have a V-shaped groove and are designed to work with V-belts, providing better grip and power transmission.

- Timing Belt Pulleys: These pulleys have teeth or grooves that match with timing belts, ensuring precise power transmission, especially in applications that require synchronization.

- Idler Pulleys: These pulleys are used to maintain tension in belts, ropes, or cables and change the direction of the belt without transmitting power.

- Variable Speed Pulleys: These pulleys have adjustable groove widths, allowing for variable speed control by changing the effective diameter of the pulley.

- Multiple Groove Pulleys: These pulleys have multiple grooves to accommodate multiple belts or cables, enabling the transmission of power to multiple components.

3. Specialty Pulleys:

In addition to standard configurations, there are specialty pulleys designed for specific applications. For example:

- Wire Rope Pulleys: These pulleys are specifically designed for wire rope applications, providing proper groove dimensions and load distribution for wire ropes.

- High-Speed Pulleys: These pulleys are engineered for high-speed applications, incorporating features such as dynamic balancing and precision machining to ensure reliable operation at high rotational speeds.

- Corrosion-Resistant Pulleys: These pulleys are made from stainless steel or other corrosion-resistant materials, suitable for applications in corrosive environments or industries.

- Customized Pulleys: Manufacturers can also provide custom-designed pulleys tailored to specific application requirements, taking into account factors such as load capacity, speed, dimensions, and environmental conditions.

The availability of different sizes and configurations allows users to select the most appropriate steel pulleys for their specific application needs. This ensures optimal performance, efficient power transmission, and extended pulley life.

What is the impact of corrosion resistance in steel pulleys when used in corrosive environments?

Corrosive environments can have a significant impact on steel pulleys, and corrosion resistance plays a crucial role in mitigating these effects. Here’s a detailed explanation:

When steel pulleys are used in corrosive environments, such as those exposed to moisture, humidity, chemicals, or saltwater, they are susceptible to corrosion. Corrosion is a natural electrochemical process that causes the gradual degradation and deterioration of metals.

The impact of corrosion on steel pulleys can be detrimental and lead to several negative consequences:

1. Structural Integrity:

Corrosion can compromise the structural integrity of steel pulleys. It weakens the metal, leading to cracks, pitting, or deformation. As the corrosion progresses, the pulleys may become structurally compromised, increasing the risk of failure or breakage. This can result in safety hazards, equipment downtime, and potential damage to other components.

2. Reduced Performance:

Corroded steel pulleys may exhibit reduced performance in terms of their functionality and efficiency. Corrosion can cause increased friction between the pulley and the belt or rope, leading to higher energy consumption, decreased power transmission efficiency, and accelerated wear of the pulley and the mating components. This can result in decreased overall system performance and increased maintenance requirements.

3. Belt or Rope Damage:

Corrosion on steel pulleys can cause damage to the belt or rope that runs over them. The corroded surfaces may have rough spots, sharp edges, or irregularities that can abrade or tear the belt or rope. This can lead to premature belt or rope failure, necessitating frequent replacements and increasing operational costs.

4. Increased Maintenance and Replacement Costs:

Corrosion-related issues in steel pulleys can result in higher maintenance and replacement costs. Regular cleaning, lubrication, and inspection are required to prevent and manage corrosion. If the pulleys become severely corroded, they may need to be replaced entirely, adding to the maintenance expenses and causing additional downtime for equipment.

5. Environmental Impact:

Corrosion of steel pulleys in corrosive environments can have environmental implications. Corrosion products, such as rust, can contaminate the surrounding environment, including soil, water bodies, or nearby equipment. This can have adverse effects on ecosystems and may require additional cleanup or remediation efforts.

To mitigate the impact of corrosion in steel pulleys used in corrosive environments, it is essential to consider and implement corrosion-resistant measures:

1. Material Selection:

Choosing steel pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, can significantly enhance their resistance to corrosion. These materials have protective layers or alloy compositions that provide a barrier against corrosive agents.

2. Protective Coatings:

Applying protective coatings, such as paints, epoxies, or specialized corrosion-resistant coatings, can help create an additional barrier between the steel pulleys and the corrosive environment. These coatings act as sacrificial layers that prevent direct contact between the pulleys and corrosive agents.

3. Regular Maintenance:

Implementing a proactive maintenance program is crucial to prevent and manage corrosion in steel pulleys. Regular cleaning, inspection, and lubrication can help remove corrosive substances, detect early signs of corrosion, and ensure proper functioning of the pulleys.

4. Environmental Controls:

Implementing environmental controls, such as proper ventilation, humidity control, or the use of protective enclosures, can help reduce the exposure of steel pulleys to corrosive elements. Minimizing direct contact with moisture, chemicals, or saltwater can significantly extend the lifespan of the pulleys.

By considering the impact of corrosion and taking appropriate measures to enhance corrosion resistance, the performance, durability, and lifespan of steel pulleys can be significantly improved in corrosive environments.

How does the design of steel pulleys impact their load-bearing capacity and efficiency?

The design of steel pulleys plays a crucial role in determining their load-bearing capacity and efficiency. Here’s a detailed explanation:

1. Diameter and Width:

The diameter and width of a steel pulley directly impact its load-bearing capacity. Larger diameter pulleys distribute the load over a greater surface area, reducing stress and increasing the pulley’s capacity to handle heavier loads. Similarly, wider pulleys provide more contact area for the belt, rope, or cable, allowing for improved load distribution and increased load-bearing capacity.

2. Groove Profile:

The groove profile of a steel pulley affects its efficiency and load-bearing capacity. Different groove profiles, such as V-shaped, U-shaped, or flat, are designed to accommodate specific types of belts, ropes, or cables. The groove profile should match the corresponding belt or cable to ensure proper engagement, minimize slippage, and maximize the load-carrying capability of the pulley.

3. Flanges and Guards:

Pulleys can be designed with flanges or guards on the sides to prevent the belt, rope, or cable from slipping off during operation. Flanges provide guidance and keep the material being conveyed centered on the pulley, enhancing the load-bearing capacity and efficiency. Guards also protect the belt or cable from external elements, reducing the risk of damage and improving overall performance.

4. Bearing Type and Arrangement:

The type and arrangement of bearings in a steel pulley significantly impact its load-bearing capacity and efficiency. High-quality bearings, such as deep groove ball bearings or roller bearings, reduce friction and enable smooth rotation, enhancing the efficiency of power transmission. Proper bearing arrangement, such as using multiple bearings or incorporating bearing supports, ensures optimal load distribution and improves the pulley’s ability to handle higher loads.

5. Material Selection:

The choice of steel material for pulley construction affects both load-bearing capacity and efficiency. High-strength steel alloys or heat-treated steels provide greater load-carrying capacity and resistance to wear or deformation. The material should be selected based on the specific application requirements, considering factors such as load magnitude, operating conditions, and environmental factors.

6. Balanced Design:

A well-balanced design is essential for efficient and reliable operation. Imbalances in the pulley design can cause vibration, increased wear, and reduced load-bearing capacity. Proper balancing techniques, such as counterweights or precision machining, ensure smooth rotation, minimize stress on the pulley and associated components, and optimize load-bearing capacity.

7. Alignment and Installation:

The proper alignment and installation of steel pulleys are critical for their load-bearing capacity and efficiency. Pulleys should be aligned accurately with the drive system to prevent misalignment-induced stress and premature wear. Correct installation techniques, such as applying proper tension to belts or cables, ensure optimal power transmission and efficient load-bearing performance.

In summary, the design of steel pulleys directly impacts their load-bearing capacity and efficiency through factors such as diameter and width, groove profile, flanges and guards, bearing type and arrangement, material selection, balanced design, and proper alignment and installation. By considering these design aspects, manufacturers can optimize the performance and capabilities of steel pulleys, enabling them to handle higher loads, minimize energy losses, and operate with greater efficiency.

editor by CX

2024-04-26