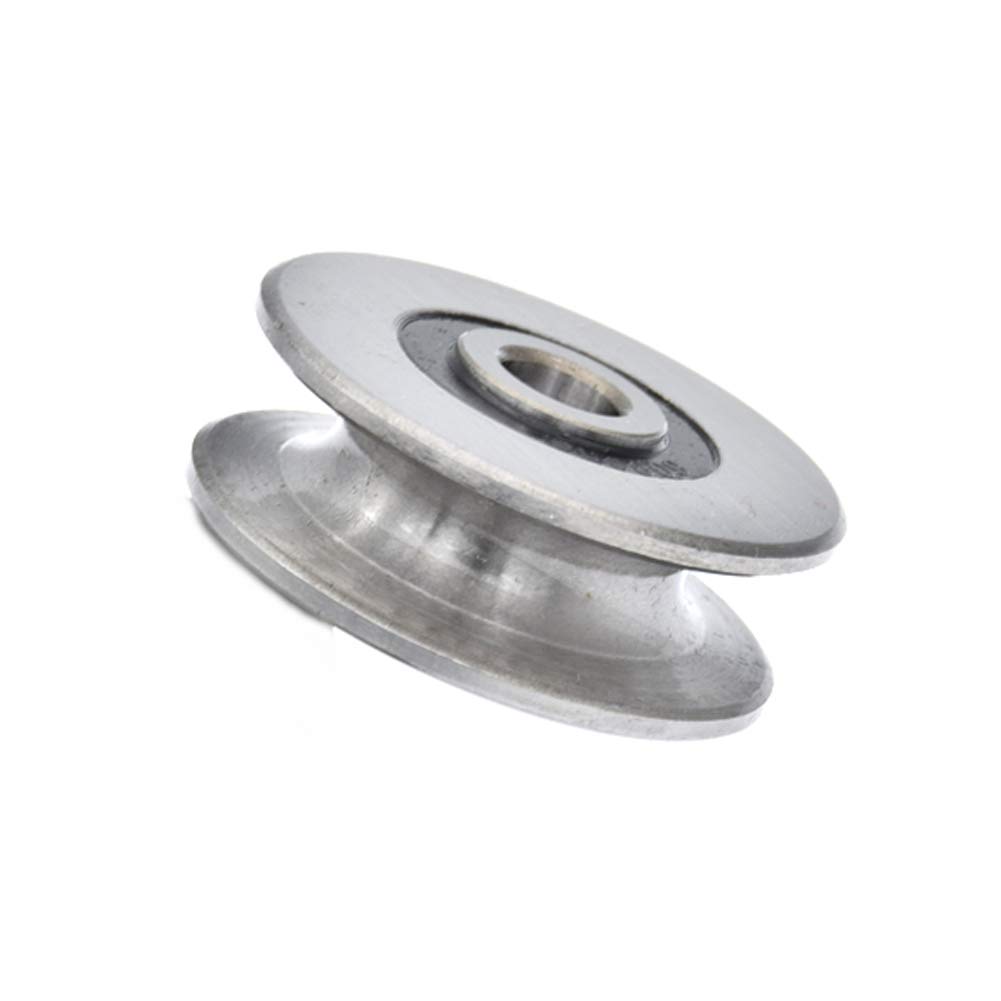

Product Description

CEMA standard stainless steel idler pulley

CHINAMFG Conveyor Pulley Specification:

1. Pulley Diameter: 250-1800mm.

2. Belt width: 300mm to 2400mm.

3. Length: Depend on the belt width.

4. Welding: Carbon dioxide arc welding, argon arc welding, electrode welding etc.; In accordance with AWS standard or substitute welding standard

5. Lagging: Cold lagging; Hot vulcanized lagging, ceramic lagging

6. Pulley tube material: Q235 seamless carbon steel.

7. Professional pulley production line.

8. Professional designing and inspection team.

9. Certification: ISO, BV, etc

Type of Conveyor Pulley:

Conveyor tail pulley

Conveyor head pulley

Conveyor rubber lagging pulley

Conveyor steel pulley

Conveyor driving pulley

Conveyor turnaround pulley

Pattern conveyor pulley

Conveyor pulley

Rubber conveyor pulley

Head pulley etc.

Conveyor Head Tail pulley:

Head pulley can be divided into driving pulley (head pulley) and thurn about pulley (tail pulley), driving pulley is the main part for transmitting the power: Smooth surface and rubber surface, and rubber surface can be classified into smooth rubber surface, herringbone rubber surface and CHINAMFG rubber surface to meet different technical requirements. Averting pulley can be classified into smooth rubber surface and smooth steel surface.

Construction

All the pulley adopt integrated bearing housing which is lubricated and filled with grease and has 2 kinds: Iron casting and steel casting, the shaft is made of 45#steel, the shell adopt weld assembly.

Our best quality based on:

Manufacturer

Experience in Cooperate with Fortune 500 Companies

Professional Engineering Capability

Stable Quality

Reasonable Price

Small Orders Accepted

Continuous Improvements

High Product Performance

Prompt Delivery

Professional Service

For more details, please inquiry us!

Polyester conveyor belt, (EP)

Nylon conveyor belt, (NN)

Cotton conveyor belt, (CC)

Sidewall conveyor belt (SW)

Steel Cord conveyor belt ( ST )

Chevron conveyor belt, (C5 C10 and C15)

Oil Resistance conveyor belt, (OR and MOR)

Hot Resistance conveyor belt, (HR)

Fire Resistance conveyor belt, (FR/PVC/PVG)

Heat Resistance conveyor belt, (HR/ FR)

Cold Resistance conveyor belts, (CR)

Pattern conveyor belt ( 30+ Moulds)

Metal Mesh conveyor belt (Heat resistant temp until 800c)

Endless belts

Conveyor roller, idler

Conveyor Pulley, frame, bracket etc

| Type | Belt width (mm) | Standard Diameter(mm) | Length (mm) |

| Drive Head Pulley | 500 | 500 | Length of the pulley depends on the belt width of the conveyor |

| 650 | 500, 630 | ||

| 800 | 500, 630, 800 | ||

| 1000 | 630, 800, 1000 | ||

| 1200 | 630, 800, 1000 | ||

| 1400 | 800, 1000 | ||

| Tail Pulley | 500 | 250, 315, 400, 500 | |

| 650 | 250, 315, 400, 500 | ||

| 800 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1000 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1200 | 250, 315, 400, 500, 630, 800, 1000 | ||

| 1400 | 250, 315, 400, 500, 630, 800, 1000 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Handling Machinery |

|---|---|

| Material: | 45# Steel, Rubber and etc |

| Color: | Available |

| Certificate: | ISO9001, SGS, Bureau Veritas |

| Application: | Coal Mining Industry, Cement |

| Bearing: | SKF, FAG, NSK, NTN, Hrb etc |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can steel pulleys withstand harsh environmental conditions and extreme temperatures?

Steel pulleys are known for their durability and ability to withstand a wide range of environmental conditions, including harsh environments and extreme temperatures. Here’s a detailed explanation:

1. Harsh Environmental Conditions:

Steel pulleys are designed to be resistant to various environmental factors, such as moisture, chemicals, dust, and abrasives. They are commonly used in industries like mining, construction, and manufacturing, where they may be exposed to harsh conditions. The specific resistance of steel pulleys to different environmental factors depends on the type of steel used and any additional protective coatings or treatments applied to the pulleys.

2. Corrosion Resistance:

Steel pulleys can be made from corrosion-resistant materials, such as stainless steel or coated steel, to enhance their resistance to rust and corrosion. These materials are particularly suitable for applications where pulleys are exposed to moisture, saltwater, or corrosive chemicals.

3. Extreme Temperatures:

Steel pulleys are capable of withstanding a wide range of temperatures. The specific temperature limits depend on the type of steel used and its heat resistance properties. Standard carbon steel pulleys can typically handle temperatures ranging from -40°C (-40°F) to 200°C (392°F) without significant loss of performance. However, for applications involving extremely high temperatures, specialized alloys or heat-resistant materials may be used.

4. Thermal Expansion:

Steel pulleys are designed to accommodate thermal expansion and contraction that occurs with temperature changes. This allows the pulleys to maintain their structural integrity and performance even when subjected to temperature variations.

5. Insulation and Cooling:

In certain applications where extreme temperatures are present, additional insulation or cooling measures may be implemented to protect the steel pulleys. Insulation materials can help minimize heat transfer to the pulleys, while cooling systems such as air circulation or liquid cooling can dissipate excess heat generated during operation.

6. Application Considerations:

While steel pulleys are generally robust and can withstand harsh environmental conditions and extreme temperatures, it’s essential to consider the specific application requirements. Factors such as the duration and frequency of exposure to extreme conditions, the mechanical loads applied, and the presence of any corrosive agents should be taken into account to ensure the pulleys are appropriately selected and maintained.

In summary, steel pulleys are designed to withstand harsh environmental conditions and a wide range of temperatures. Their resistance to corrosion, durability, and thermal properties make them suitable for various industrial applications. However, for extreme conditions, it may be necessary to choose specialized materials or implement additional protective measures to ensure optimal performance and longevity.

How do steel pulleys compare to other materials, such as plastic or aluminum, in various scenarios?

Steel pulleys, plastic pulleys, and aluminum pulleys each have their own advantages and considerations in different scenarios. Here’s a detailed comparison:

1. Strength and Durability:

Steel pulleys generally offer higher strength and durability compared to plastic or aluminum pulleys. Steel has excellent load-bearing capacity and can withstand heavy loads and high forces without deformation. Plastic pulleys are lightweight but may have lower strength and may not be suitable for heavy-duty applications. Aluminum pulleys offer a good balance between strength and weight, but they may not be as durable as steel pulleys in certain demanding scenarios.

2. Corrosion Resistance:

Steel pulleys often exhibit better corrosion resistance compared to aluminum pulleys, especially when made from stainless steel or galvanized steel. Plastic pulleys are inherently corrosion-resistant, which makes them suitable for applications where exposure to moisture or chemicals is a concern. Aluminum pulleys may require additional protective coatings or treatments to enhance their corrosion resistance.

3. Weight:

Plastic and aluminum pulleys are generally lighter than steel pulleys. In applications where weight reduction is critical, such as in industries like aerospace or automotive, plastic or aluminum pulleys may be preferred. However, it is important to consider the load requirements and select a material that can handle the anticipated forces without compromising safety or performance.

4. Friction and Wear:

Steel pulleys typically have smoother surfaces and better wear resistance compared to plastic pulleys. The smooth surfaces of steel pulleys reduce friction and wear on the belt or rope, contributing to improved efficiency and longevity. Plastic pulleys may have higher friction coefficients and may require additional lubrication or specialized coatings to reduce wear. Aluminum pulleys can have good wear resistance but may not be as durable as steel pulleys in high-load or abrasive environments.

5. Temperature Resistance:

Steel pulleys generally have better temperature resistance compared to plastic pulleys. Steel can withstand higher temperatures without deformation or loss of strength. Plastic pulleys may have limitations in high-temperature applications due to their lower melting points. Aluminum pulleys have good heat dissipation properties but may experience thermal expansion.

6. Cost:

Steel pulleys are often more cost-effective compared to aluminum pulleys, especially for larger or heavy-duty applications. Plastic pulleys can be cost-effective for certain low-load or non-critical applications. Aluminum pulleys are generally more expensive than steel pulleys but offer advantages in terms of weight savings and specific applications where their properties are advantageous.

7. Noise and Vibration:

Steel pulleys tend to produce less noise and vibration compared to plastic pulleys. Steel’s higher density and rigidity help dampen vibrations and reduce noise levels. Plastic pulleys may generate more noise and vibration, particularly at high speeds or under heavy loads. Aluminum pulleys can offer good vibration damping properties but may not be as effective as steel in certain scenarios.

In summary, the choice between steel, plastic, or aluminum pulleys depends on the specific requirements of the application. Steel pulleys offer superior strength, durability, corrosion resistance, and wear resistance, making them suitable for heavy-duty and demanding scenarios. Plastic pulleys are lightweight, corrosion-resistant, and cost-effective for certain low-load applications. Aluminum pulleys provide a balance between strength and weight, making them advantageous in weight-sensitive applications. Consideration should be given to factors such as load requirements, environmental conditions, temperature, cost, and performance characteristics to determine the most suitable pulley material for a given scenario.

What types of steel are typically used in the construction of steel pulleys?

Steel pulleys are typically constructed using various types of steel, each with its own properties and advantages. Here’s a detailed explanation:

1. Carbon Steel:

Carbon steel is a common choice for steel pulleys due to its high strength and affordability. It contains primarily iron and carbon, with small amounts of other elements. Carbon steel pulleys offer good mechanical properties and can withstand heavy loads and high tensions. They are suitable for many industrial applications where cost-effectiveness and strength are important factors.

2. Alloy Steel:

Alloy steel pulleys are made by adding alloying elements such as chromium, nickel, or molybdenum to carbon steel. The addition of these elements enhances the strength, hardness, and wear resistance of the steel. Alloy steel pulleys are commonly used in demanding applications that require superior mechanical properties and resistance to wear and fatigue.

3. Stainless Steel:

Stainless steel pulleys are highly corrosion-resistant and are often employed in environments where exposure to moisture, chemicals, or harsh conditions is expected. Stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing corrosion. Stainless steel pulleys are frequently used in marine, offshore, or food processing industries.

4. Heat-Treated Steel:

Heat-treated steel pulleys undergo a heat treatment process to enhance their mechanical properties. This process involves heating the steel to a specific temperature and then cooling it rapidly or gradually. Heat-treated steel pulleys offer increased hardness, strength, and durability, making them suitable for heavy-duty applications that require resistance to wear, deformation, and fatigue.

5. Case-Hardened Steel:

Case-hardened steel pulleys have a hard and wear-resistant outer surface while maintaining toughness and ductility in the core. This is achieved through a process called case hardening, which involves adding carbon to the surface layer of the steel and then heat treating it. Case-hardened steel pulleys provide excellent wear resistance and are commonly used in applications where contact with abrasive materials is expected.

6. Galvanized Steel:

Galvanized steel pulleys have a protective zinc coating applied to their surface through a process called galvanization. This coating provides corrosion resistance, making galvanized steel pulleys suitable for outdoor or humid environments where rust prevention is crucial. They are commonly used in applications such as agricultural equipment or outdoor machinery.

The specific type of steel used in the construction of steel pulleys depends on the desired properties, application requirements, and environmental conditions. Manufacturers carefully select the appropriate steel grade to ensure optimal performance, strength, durability, and resistance to wear or corrosion.

editor by CX

2024-05-07