Product Description

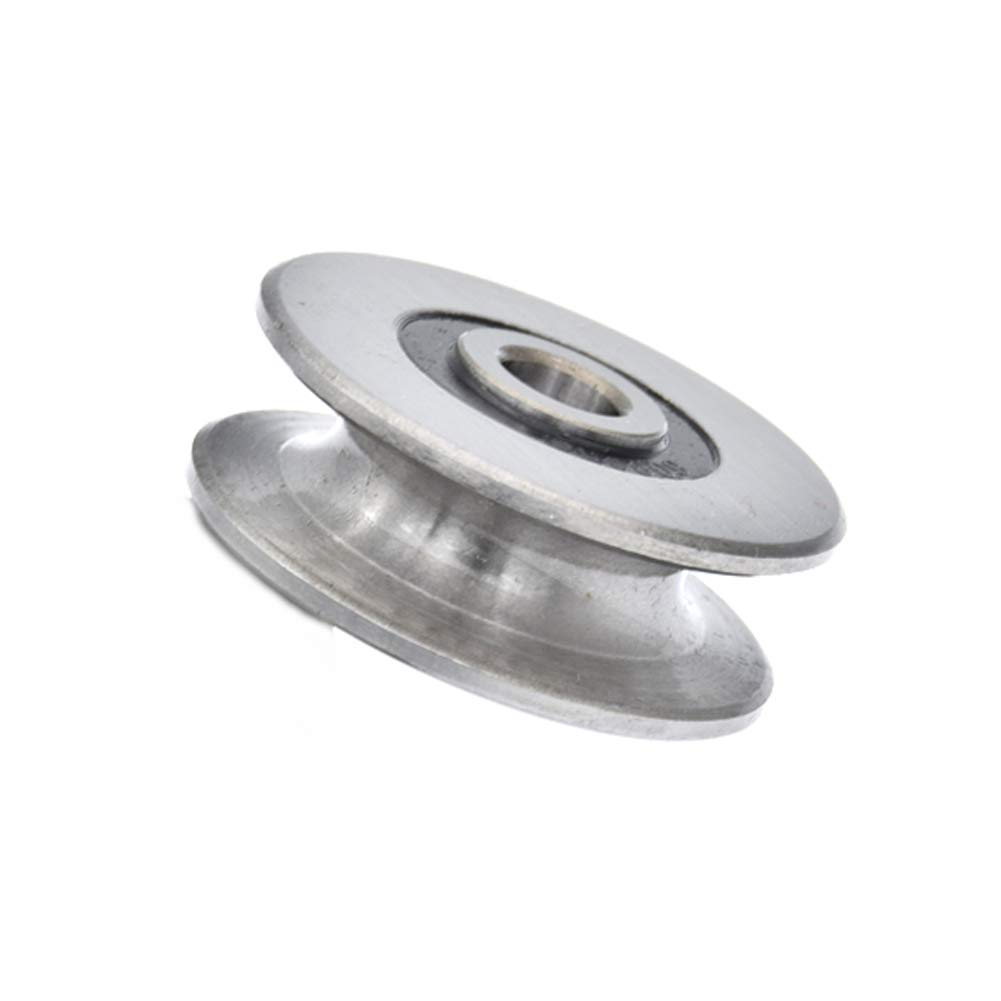

Single Bearing Trapezoid Gate Wheel

| Model | A | B | C | D | E | Weight (Y) Units:g |

Weight (U) Units:g |

Weight (V) Units:g |

| 30×11 | 35 | 11 | 30 | 45 | 17 | * | * | 63 |

| 40×14 | 45 | 14 | 38 | 75 | 25 | 192 | 185 | 194 |

| 50×15 | 55 | 15 | 48 | 75 | 25 | 253 | 244 | 263 |

| 50×15 | 60 | 15 | 48 | 85 | 30 | 303 | 292 | 302 |

| 60×17 | 65 | 20 | 58 | 85 | 30 | 400 | 395 | 410 |

| 70×20 | 80 | 20 | 68 | 100 | 35 | 640 | 640 | 665 |

| 80×20 | 85 | 20 | 48 | 100 | 35 | 805 | 785 | 825 |

| 90×20 | 100 | 20 | 88 | 133 | 35 | 1130 | 1121 | 1145 |

| 100×20 | 105 | 20 | 98 | 133 | 35 | 1350 | 1338 | 1363 |

| The data is measured by hand, maybe there are some errors, just for reference. | ||||||||

Double Bearing Gate Wheel

| Model | A | B | C | D | E | Weight(Y) | Weight(U) |

| 50MM | 55 | 26 | 48 | 85 | 30 | 324 | 320 |

| 60MM | 65 | 30 | 58 | 85 | 30 | 617 | 580 |

| 70MM | 80 | 32 | 68 | 100 | 35 | 977 | 954 |

| 80MM | 85 | 32 | 48 | 100 | 35 | 1260 | 1223 |

| 90MM | 100 | 32 | 88 | 133 | 35 | 1788 | 1760 |

| 100MM | 105 | 32 | 98 | 133 | 35 | 2100 | 2078 |

| The data is measured by hand, maybe there are some errors, just for reference. | |||||||

Laminated Gate Wheel

| Model | A | B | C | D | Weight(Y/V) | Weight(U) |

| 50mm | 48 | 15 | 100 | 26 | 260 | 250 |

| 60mm | 58 | 17 | 100 | 26 | 390 | 360 |

| 70mm | 68 | 20 | 136 | 33 | 590 | 570 |

| 80mm | 78 | 20 | 136 | 33 | 750 | 725 |

| 90mm | 88 | 20 | 152 | 33 | 1060 | 1030 |

| 100mm | 98 | 20 | 152 | 33 | 1265 | 1225 |

| The data is measured by hand, maybe there are some errors, just for reference. | ||||||

Hang Gate Wheel

| Model | A | B | C | D | E | F | G | H | I |

| H25 | 51 | 25 | M9*50 | 9 | 95 | 79 | 25 | 6 | 27 |

| H38 | 86 | 38 | M12*70 | 11 | 120 | 118 | 38 | 10 | 32 |

| H55 | 115 | 55 | M20*85 | 14 | 140 | 159 | 44 | 10 | 15 |

| The data is measured by hand, maybe there are some errors, just for reference. | |||||||||

Triangle Gate Wheels/ Rotation Gate Wheels/ Hanging Wheels/ White Zinc Gate Wheels/ Doule Wheels Double Bearing Gate Wheel

We have already had nealy a decade producting and exporting experience. Since 2014, we have sold our products to dozens of countries all around the world. And we have established a deep cooperative relationship with many customers.

We make our products with heart, strive to bring the best quality for customers. So we got a lot of customer approval. After that, we will also strictly control, down-to-earth, and forge ahead.

1.ZheJiang Joinwin Hardware and Tools Co., Ltd. we have 10 years manufacturing and exporting experience which ranks among the best in China. Mainly sales pliers, spanners, scissors, saws, screwdrivers, wheels, sillicone sealant, tapline and other hand tools.

2.Located in HangZhou where is just 180km far from HangZhou Port and many raw material factories around, greatly reduces transportation and procurement costs.

3.We have professional sales and engineers to provide satisfied service to clients. Our company covers an area of 1000 square meters, has the most advanced production equipment and technology.

4.Customer first, team work, embrace change, sincere are our company culture.

5.We aim to provide clients more safety and convenient life.

Pliers Adjustable Wrench Combination Spanners Hammers Pruner Scissors Aviation Tin Snips

Screwdrivers Padlocks Hand Saws Axe Silicone Sealant

Q1: Can I get a sample?

A1: Yes, the samples are usually free for customers.

Q2: Can you provide OEM service?

A2: Yes, we can produce the goods according to clients’ demands.

Q3: How can you guarantee the quality?

A3: We have advanced equipment and professional engineer and quality inspector to ensure the quality of the goods. And we will send extra goods for insurance. Besides, we have satisfied after-service.

Q4: What is the MOQ?

A4: 500 PCS.

Q5: How long you will finish my order?

A5: Totally in 30 days. (The specific situation depends on the production schedule of the production department.) /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 5 Years |

|---|---|

| Warranty: | 3 Years |

| Certification: | CE |

| Splittable: | Splittable |

| Surface Treatment: | Zinc Plated |

| Material: | Metal |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can steel pulleys withstand harsh environmental conditions and extreme temperatures?

Steel pulleys are known for their durability and ability to withstand a wide range of environmental conditions, including harsh environments and extreme temperatures. Here’s a detailed explanation:

1. Harsh Environmental Conditions:

Steel pulleys are designed to be resistant to various environmental factors, such as moisture, chemicals, dust, and abrasives. They are commonly used in industries like mining, construction, and manufacturing, where they may be exposed to harsh conditions. The specific resistance of steel pulleys to different environmental factors depends on the type of steel used and any additional protective coatings or treatments applied to the pulleys.

2. Corrosion Resistance:

Steel pulleys can be made from corrosion-resistant materials, such as stainless steel or coated steel, to enhance their resistance to rust and corrosion. These materials are particularly suitable for applications where pulleys are exposed to moisture, saltwater, or corrosive chemicals.

3. Extreme Temperatures:

Steel pulleys are capable of withstanding a wide range of temperatures. The specific temperature limits depend on the type of steel used and its heat resistance properties. Standard carbon steel pulleys can typically handle temperatures ranging from -40°C (-40°F) to 200°C (392°F) without significant loss of performance. However, for applications involving extremely high temperatures, specialized alloys or heat-resistant materials may be used.

4. Thermal Expansion:

Steel pulleys are designed to accommodate thermal expansion and contraction that occurs with temperature changes. This allows the pulleys to maintain their structural integrity and performance even when subjected to temperature variations.

5. Insulation and Cooling:

In certain applications where extreme temperatures are present, additional insulation or cooling measures may be implemented to protect the steel pulleys. Insulation materials can help minimize heat transfer to the pulleys, while cooling systems such as air circulation or liquid cooling can dissipate excess heat generated during operation.

6. Application Considerations:

While steel pulleys are generally robust and can withstand harsh environmental conditions and extreme temperatures, it’s essential to consider the specific application requirements. Factors such as the duration and frequency of exposure to extreme conditions, the mechanical loads applied, and the presence of any corrosive agents should be taken into account to ensure the pulleys are appropriately selected and maintained.

In summary, steel pulleys are designed to withstand harsh environmental conditions and a wide range of temperatures. Their resistance to corrosion, durability, and thermal properties make them suitable for various industrial applications. However, for extreme conditions, it may be necessary to choose specialized materials or implement additional protective measures to ensure optimal performance and longevity.

What is the impact of corrosion resistance in steel pulleys when used in corrosive environments?

Corrosive environments can have a significant impact on steel pulleys, and corrosion resistance plays a crucial role in mitigating these effects. Here’s a detailed explanation:

When steel pulleys are used in corrosive environments, such as those exposed to moisture, humidity, chemicals, or saltwater, they are susceptible to corrosion. Corrosion is a natural electrochemical process that causes the gradual degradation and deterioration of metals.

The impact of corrosion on steel pulleys can be detrimental and lead to several negative consequences:

1. Structural Integrity:

Corrosion can compromise the structural integrity of steel pulleys. It weakens the metal, leading to cracks, pitting, or deformation. As the corrosion progresses, the pulleys may become structurally compromised, increasing the risk of failure or breakage. This can result in safety hazards, equipment downtime, and potential damage to other components.

2. Reduced Performance:

Corroded steel pulleys may exhibit reduced performance in terms of their functionality and efficiency. Corrosion can cause increased friction between the pulley and the belt or rope, leading to higher energy consumption, decreased power transmission efficiency, and accelerated wear of the pulley and the mating components. This can result in decreased overall system performance and increased maintenance requirements.

3. Belt or Rope Damage:

Corrosion on steel pulleys can cause damage to the belt or rope that runs over them. The corroded surfaces may have rough spots, sharp edges, or irregularities that can abrade or tear the belt or rope. This can lead to premature belt or rope failure, necessitating frequent replacements and increasing operational costs.

4. Increased Maintenance and Replacement Costs:

Corrosion-related issues in steel pulleys can result in higher maintenance and replacement costs. Regular cleaning, lubrication, and inspection are required to prevent and manage corrosion. If the pulleys become severely corroded, they may need to be replaced entirely, adding to the maintenance expenses and causing additional downtime for equipment.

5. Environmental Impact:

Corrosion of steel pulleys in corrosive environments can have environmental implications. Corrosion products, such as rust, can contaminate the surrounding environment, including soil, water bodies, or nearby equipment. This can have adverse effects on ecosystems and may require additional cleanup or remediation efforts.

To mitigate the impact of corrosion in steel pulleys used in corrosive environments, it is essential to consider and implement corrosion-resistant measures:

1. Material Selection:

Choosing steel pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, can significantly enhance their resistance to corrosion. These materials have protective layers or alloy compositions that provide a barrier against corrosive agents.

2. Protective Coatings:

Applying protective coatings, such as paints, epoxies, or specialized corrosion-resistant coatings, can help create an additional barrier between the steel pulleys and the corrosive environment. These coatings act as sacrificial layers that prevent direct contact between the pulleys and corrosive agents.

3. Regular Maintenance:

Implementing a proactive maintenance program is crucial to prevent and manage corrosion in steel pulleys. Regular cleaning, inspection, and lubrication can help remove corrosive substances, detect early signs of corrosion, and ensure proper functioning of the pulleys.

4. Environmental Controls:

Implementing environmental controls, such as proper ventilation, humidity control, or the use of protective enclosures, can help reduce the exposure of steel pulleys to corrosive elements. Minimizing direct contact with moisture, chemicals, or saltwater can significantly extend the lifespan of the pulleys.

By considering the impact of corrosion and taking appropriate measures to enhance corrosion resistance, the performance, durability, and lifespan of steel pulleys can be significantly improved in corrosive environments.

How does the steel construction of pulleys contribute to their durability and strength?

The steel construction of pulleys plays a significant role in their durability and strength. Here’s a detailed explanation:

1. Material Strength:

Steel is renowned for its exceptional strength. It has a high tensile strength, which means it can withstand substantial loads and forces without deforming or breaking. The use of steel in pulley construction ensures that the pulleys can handle heavy loads and high tensions encountered in lifting and tensioning tasks.

2. Resistance to Deformation:

Steel has excellent resistance to deformation under stress. Pulleys experience significant forces and pressures during operation, especially when handling heavy loads. The inherent strength of steel helps prevent deformation, ensuring that the pulleys maintain their shape and functionality over time.

3. Fatigue Resistance:

Steel exhibits high fatigue resistance, meaning it can withstand repeated loading and unloading cycles without failure. In lifting and tensioning tasks, pulleys are subjected to cyclic stress as loads are lifted, lowered, or tensioned. The fatigue resistance of steel ensures that the pulleys can endure these cyclic loads without developing cracks or fractures.

4. Wear Resistance:

Steel pulleys offer excellent wear resistance due to their hardness and surface properties. As ropes, cables, or belts pass over the pulley surfaces, friction occurs, leading to wear. The use of steel, especially alloy steel or case-hardened steel, helps minimize wear and prolong the pulleys’ lifespan, ensuring continued performance and reliability.

5. Corrosion Resistance:

Steel pulleys can be manufactured using corrosion-resistant steel alloys or by applying protective coatings such as galvanization or stainless steel cladding. These measures enhance the pulleys’ resistance to corrosion, making them suitable for applications in harsh environments or industries where exposure to moisture, chemicals, or corrosive substances is common.

6. Structural Integrity:

The structural integrity of steel contributes to the overall durability and strength of pulleys. Steel is a rigid and stable material, capable of maintaining its shape and dimensional stability even under heavy loads or extreme conditions. This structural integrity ensures that the pulleys remain stable and reliable during operation.

7. Design Flexibility:

Steel’s versatility allows for various design options in pulley construction. Manufacturers can design pulleys with different sizes, shapes, and configurations to suit specific application requirements. This flexibility in design ensures that the pulleys can be optimized for strength, load distribution, and efficient operation.

In summary, the steel construction of pulleys contributes to their durability and strength through material strength, resistance to deformation, fatigue resistance, wear resistance, corrosion resistance, structural integrity, and design flexibility. These properties make steel pulleys capable of withstanding heavy loads, resisting wear and corrosion, and maintaining their performance and reliability over an extended period.

editor by CX

2024-05-09