Product Description

Company Profile

HangZhou Doerbee International Trade Co. , Ltd. , located in HangZhou hi-tech Development Zone, ZheJiang Province, the company’s main auto parts, mechanical and electrical supplies. Our company has established long-term and stable cooperative relations with many auto parts factories in ZHangZhoug and ZheJiang provinces. We value credit, abide by contracts, guarantee product quality, win the trust of our customers, and make every effort to follow their needs, continuous product innovation and service improvement. OEM, sample can be customized. We will gradually improve the product types and details, if you have non-standard products need us to help you find Chinese manufacturers, please contact us, send samples, we will be your most responsible and professional partner in China. Looking CHINAMFG to working with you.

Every month, we will go back and forth to each auto parts manufacturer to find and compare all kinds of high quality and low price products for you. If you have samples, but can not confirm the model or name, you can also send samples to us, we will try our best to find out the sample manufacturers in China, compare the quality for you, and provide quotation. We represent all kinds of auto parts and mechanical and electrical products, in the future we will continue to improve the product category, please pay attention to us, any need, please feel free to contact us. At present, there are more than 3.3

Q1. How to buy?

A1:Large quantity for more discount : Inquiry → Quotation → Price resonable → Check with specification → Proforma Invoice sent → Payment made → Product shipment → Customer

Q2. What is your terms of payment?

A2:T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A3:Generally, it will take 20 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A4:Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A5:We can supply the sample if we have ready parts in stock, but the customers have to pay the sample and courier cost.

Q6. Do you test all your goods before delivery?

A6:Yes, We will take 100% testing and photos before delivery, and keep communication with you at any time.

Q7: How do you make our business long-term and good relationship?

A7:We are not only partners, but also friends. We will try our best to provide you with the most cost-effective products. If you have any goods that are difficult to purchase, we will try our best to find them in China. We will become your most trusted buyers in China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 100000 Km |

|---|---|

| Warranty: | 2 Years |

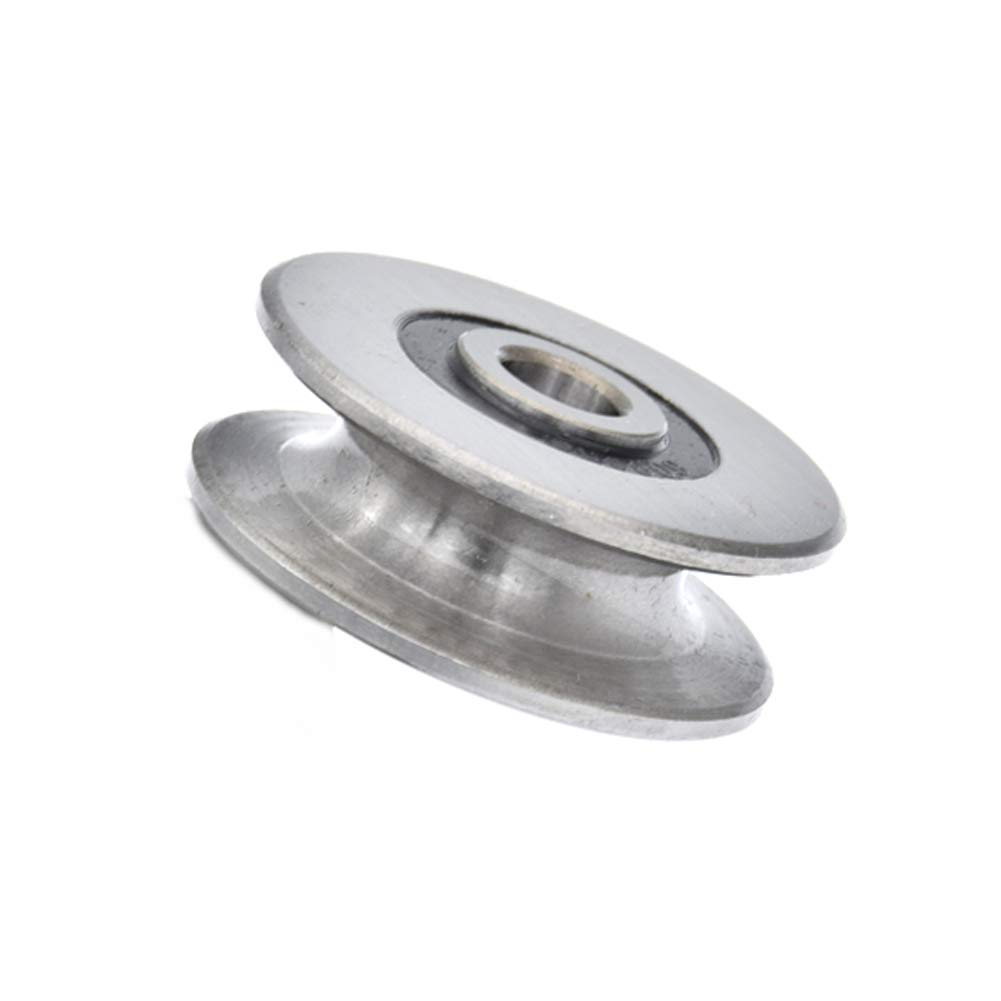

| Type: | Auto Clutch Bearing |

| Material: | Carbon Steel |

| Tolerance: | P5 |

| Certification: | TS16949 |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do steel pulleys enhance the precision and control of various mechanical operations?

Steel pulleys play a crucial role in enhancing the precision and control of various mechanical operations. Here’s a detailed explanation:

1. Power Transmission:

Steel pulleys are used in conjunction with belts, ropes, or cables to transmit power from one component to another. By utilizing the mechanical advantage of pulleys, it becomes possible to control and regulate the speed, torque, and direction of the transmitted power. This enables precise control over the mechanical operation and facilitates the achievement of desired outcomes.

2. Mechanical Advantage:

Steel pulleys leverage the concept of mechanical advantage to enhance precision and control. The ratio of the diameters or number of grooves in the pulley system determines the mechanical advantage achieved. By selecting the appropriate pulley size and configuration, mechanical operations can be fine-tuned to optimize performance and control variables such as speed, force, and motion.

3. Speed Control:

Steel pulleys, especially those with variable speed capabilities, enable precise speed control in mechanical operations. By adjusting the effective diameter of the pulley, the rotational speed of the driven component can be modified. This is particularly useful in applications where speed regulation is critical, such as in machinery used for manufacturing, processing, or automation.

4. Torque Transfer:

Pulleys facilitate the transfer of torque from the driving component to the driven component. The size and configuration of the pulleys, along with the tension in the connecting belt or cable, determine the torque transmitted. By carefully selecting the pulley system, the torque can be controlled and distributed as required, ensuring precise and reliable torque transfer for mechanical operations.

5. Synchronization:

In certain applications, precise synchronization of mechanical operations is essential. Steel pulleys, when used in conjunction with timing belts or chains, enable accurate synchronization between multiple components. This is commonly seen in applications such as conveyor systems, robotic arms, or printing presses, where coordinated motion is critical for proper functioning and precision.

6. Control over Mechanical Loads:

Steel pulleys provide control over mechanical loads by managing tension and distributing forces. By properly tensioning the belts, ropes, or cables, the pulleys ensure that the load is evenly distributed across the system, minimizing the risk of slippage, excessive wear, or component failures. This control over mechanical loads enhances the precision and reliability of mechanical operations.

7. Reducing Vibration and Noise:

Steel pulleys, when properly designed and balanced, help reduce vibration and noise generated during mechanical operations. Vibration and noise can negatively impact precision and control, leading to suboptimal performance or discomfort. By incorporating features such as dynamic balancing and precision machining, steel pulleys minimize vibrations and contribute to smoother, quieter mechanical operations.

In summary, steel pulleys enhance the precision and control of various mechanical operations by facilitating power transmission, leveraging mechanical advantage, enabling speed control, ensuring torque transfer, enabling synchronization, managing mechanical loads, and reducing vibration and noise. Their versatility and ability to fine-tune mechanical systems make them invaluable components in a wide range of industries and applications.

How do steel pulleys contribute to energy conservation and reduced friction in systems?

Steel pulleys play a significant role in energy conservation and reducing friction in systems. Here’s a detailed explanation:

1. Mechanical Advantage:

Steel pulleys are commonly used in mechanical systems to create a mechanical advantage. By utilizing the principle of a pulley system, where a flexible belt or rope is looped around one or more pulleys, the input force required to move a load can be reduced. This mechanical advantage allows for the transfer of a higher load with less input force, thus conserving energy.

2. Friction Reduction:

Steel pulleys are designed to minimize friction in mechanical systems. The smooth and precisely machined surfaces of steel pulleys reduce the contact area and friction between the pulley and the belt or rope. This reduction in friction results in less energy loss due to heat generation and allows for more efficient power transmission.

3. Bearing Technology:

Steel pulleys often incorporate high-quality bearings to further reduce friction. Bearings, such as ball bearings or roller bearings, enable smooth rotation of the pulley with minimal frictional resistance. The use of advanced bearing technologies in steel pulleys reduces energy consumption and enhances overall system efficiency.

4. Material Properties:

Steel is known for its excellent strength and durability. The use of steel in pulley construction allows for the design of pulleys that can withstand high loads and resist deformation. This reduces the occurrence of slippage or belt misalignment, which can cause increased friction and energy loss in the system.

5. Precision Manufacturing:

Precision manufacturing techniques employed in the production of steel pulleys contribute to reduced friction and improved energy conservation. Accurate machining and balancing ensure proper alignment and concentricity of the pulley, minimizing vibrations and reducing friction. Additionally, precision manufacturing allows for the creation of pulleys with consistent dimensions and smooth surfaces, optimizing the contact between the pulley and the belt or rope.

6. Lubrication:

Proper lubrication of steel pulleys can further reduce friction and energy consumption. Lubricants such as oils or greases are applied to the bearings and contact surfaces to minimize friction and wear. Effective lubrication ensures smooth rotation and efficient power transmission, contributing to energy conservation.

7. System Optimization:

Steel pulleys are integral components of system design and optimization. By selecting the appropriate pulley sizes, configurations, and belt types, system designers can minimize energy losses and maximize efficiency. Proper tensioning, alignment, and maintenance of steel pulleys also contribute to reducing friction and ensuring optimal system performance.

In summary, steel pulleys contribute to energy conservation and reduced friction in systems through their mechanical advantage, friction reduction, utilization of advanced bearing technology, favorable material properties, precision manufacturing techniques, lubrication, and system optimization. By incorporating steel pulleys into mechanical systems, energy losses due to friction can be minimized, leading to improved overall system efficiency.

Can you explain the advantages of using steel pulleys in lifting and tensioning tasks?

Using steel pulleys in lifting and tensioning tasks offers several advantages. Here’s a detailed explanation:

1. Strength and Durability:

Steel pulleys are known for their exceptional strength and durability. They can withstand heavy loads and high tensions without deformation or failure. This makes them ideal for lifting and tensioning tasks where robust components are essential to ensure safety and reliability.

2. Load Handling Capacity:

Steel pulleys have high load handling capacities, allowing them to handle substantial weights and tensions. They are designed to distribute the load evenly across the pulley, minimizing stress and preventing overload on individual components. This capability is crucial in lifting and tensioning applications that involve heavy objects or high forces.

3. Resistance to Wear and Corrosion:

Steel pulleys offer excellent resistance to wear and corrosion. They can withstand repeated use and exposure to harsh environmental conditions without significant deterioration. This resistance ensures the longevity of the pulleys, reducing maintenance requirements and increasing their lifespan.

4. Precise Alignment and Tracking:

Steel pulleys provide precise alignment and tracking of ropes, cables, or belts. They are manufactured with tight tolerances to ensure smooth movement and minimize friction. This precise alignment is crucial in lifting and tensioning tasks where accurate positioning and controlled movement are required.

5. Reduced Friction and Energy Loss:

Steel pulleys are designed to reduce friction and energy loss in lifting and tensioning systems. They incorporate smooth surfaces and high-quality bearings or bushings to minimize frictional resistance. By reducing friction, steel pulleys enhance the efficiency of the system, allowing for easier operation and energy savings.

6. Compatibility with Various Rope or Cable Types:

Steel pulleys are compatible with a wide range of rope or cable types, including steel cables, synthetic ropes, or high-strength fibers. They can accommodate different diameters and configurations, providing flexibility in selecting the appropriate rope or cable for specific lifting or tensioning tasks.

7. Safety and Reliability:

Using steel pulleys in lifting and tensioning tasks ensures safety and reliability. Their strength, durability, and load handling capacities contribute to the overall safety of the system, minimizing the risk of accidents or equipment failure. Additionally, their precise alignment and tracking reduce the likelihood of rope slippage or misalignment, ensuring secure and reliable operation.

In summary, the advantages of using steel pulleys in lifting and tensioning tasks include their strength, durability, high load handling capacities, resistance to wear and corrosion, precise alignment and tracking, reduced friction and energy loss, compatibility with various rope or cable types, and overall safety and reliability. These advantages make steel pulleys a preferred choice in applications where heavy loads, precise movement, and dependable performance are essential.

editor by CX

2024-04-24