Product Description

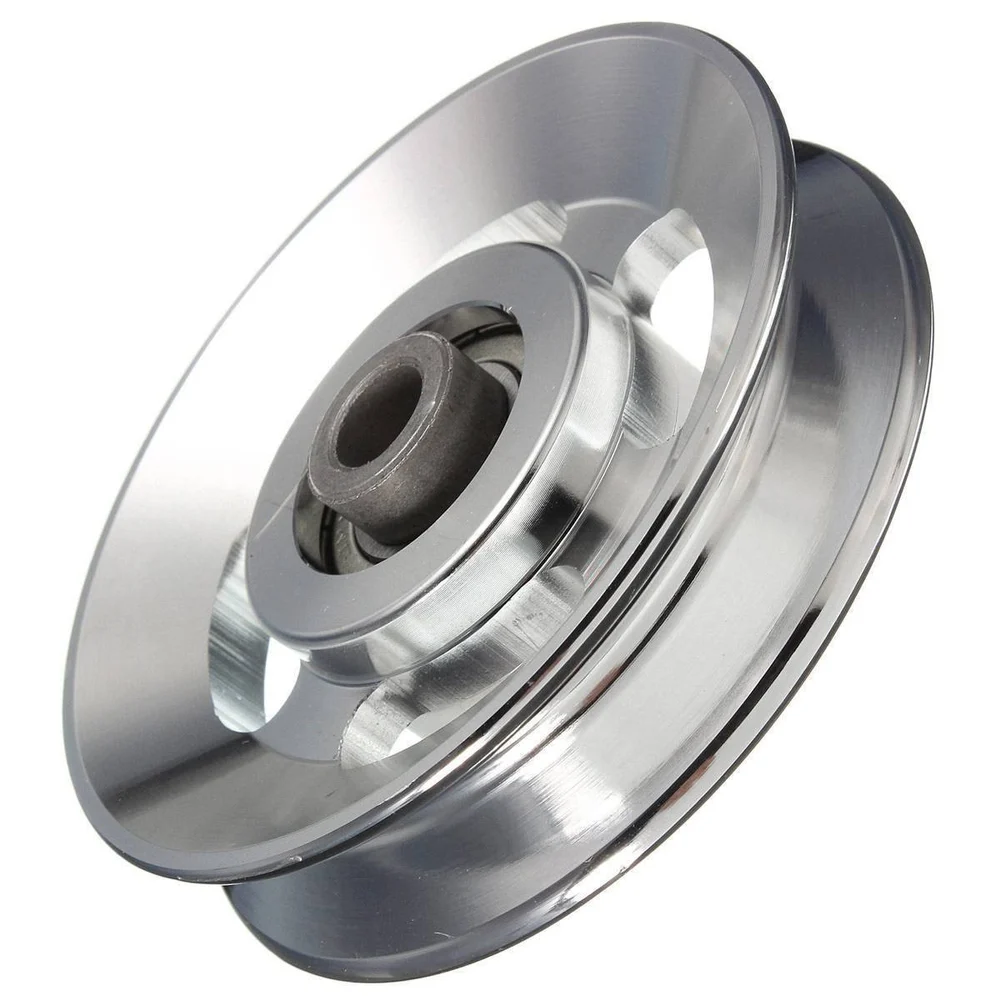

CUSTOMIZED CONVEYOR ROLLER (conveyor pulley,gravity roller/ power roller/ driven roller pulley)

DMC Roller supply different conveyor rollers including gravity roller, drive roller,drive pulley, Polyurethane (PU) covered roller, Buna Nitrile rubber(NBR) covered roller, Styrene Butadiene Rubber (SBR) covered roller, CHINAMFG rubber coating roller , Silicon rubber, NR and CR etc

The conveyor rollers are used in a variety of industries including food distribution, pharmacy,tobacco,clothing,postal express,logistic and distribution,rubber and airport industries.

We could process conveyor roller up to 6,000mm in-house and max. 12,000mm long by outsourcing. All of customized conevyor rollers are available, and we could also meet some special requirements for friction and anti-static performance, etc. In addition, we provide inspection report for every critical conveyor roller.

Description:

|

Production type |

custom OEM,ODM production conveyor (system), chain conveyor |

|||

|

Roller Materail |

SAE1571, 1045, S355J2H, Q345B, 38CrNiMo, 40Cr, Stainless steel 304L/316L and aluminum 6063&6061T651, etc. baggage handling system heavy steel rolls; quality rolls |

|||

|

Types |

idler roller, drive roller, chain roller ,tapered roller,free roller, all of Logistics equipment roller for mine conveyor |

|||

|

Shapes |

flat roll, cambered or crowned roller pulley, anilox roll |

|||

|

Standards |

customized, CEMA, TD-2, JIS, ISO small rollers steel rolls manufacturing |

|||

|

Surface Coating |

paint, powder coating, zinc plating, rubber coated solid steel rolls cylinder for machine |

|||

|

Supply Capacity |

>10,000pcs monthly complex roller logistics equipment, conveyor (system), chain conveyor |

|||

|

Assembly Service |

Available conveyor idler trough roller precision grooved roller /grooving roller |

|||

|

Application Fields |

logistics equipment, belt conveyor systems, automotive, parcel & baggage handling system, ecommerce , warehouse & distribution conveyor solution, converting machine, mine conveyor, food industry, wood processing, etc. |

|||

|

Package |

plywood box (Fumigation-free) Well-designed packaging is also very important for the qualified conveyor rollers, otherwise the conveyor pulley may be damaged in the loading/unloading process and transportation. roller |

|||

|

Also Named as |

conveyor idler, idler conveyor roller, conveyor belt roller, carrying idler, rubber idler roller, conveyor idler roller, idler pulley, rubber conveyor pulley, drum pulley, belt drive pulley, drum roller, crowned pulley, transport roller, carrier roller, conveying roller, conveyor tail pulley, belt conveyor head pulley, rubber lagging drum pulley, impact roller, etc. |

|||

|

Other Products |

industrial steel roller, rubber coated roller, aluminum cylinder, machined components, welding, sheet metal fabrication |

|||

QUALITY CONTROL

* Accept SGS and any other third party’s in-site inspection if necessary.

* Provide inspection report for each CTQ and critical part before delivery.

* Confirm the DFM with customer before sample production.

* Provide 8D report and CAR to client in case quality issue happens.

* Have regular maintenance schedule for all measuring tools.

* Strict controls and checkups are conducted on a regular basis.

* In addition, our concerning is not only part itself but also material localization, documentation of production and reasonable design of packaging for long distance transportation.

INSPECTIONS

Quality runs through the whole process from material to delivery.

We provide inspection report for each roller before shipment. The below sample reports are for your reference.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Baking Paint |

| Motor Type: | Frequency Control Motor |

| Installation: | Horizontal |

| Size: | Customer-Made |

| Transport Package: | Wooden Crate |

| Customization: |

Available

| Customized Request |

|---|

Can steel pulleys withstand harsh environmental conditions and extreme temperatures?

Steel pulleys are known for their durability and ability to withstand a wide range of environmental conditions, including harsh environments and extreme temperatures. Here’s a detailed explanation:

1. Harsh Environmental Conditions:

Steel pulleys are designed to be resistant to various environmental factors, such as moisture, chemicals, dust, and abrasives. They are commonly used in industries like mining, construction, and manufacturing, where they may be exposed to harsh conditions. The specific resistance of steel pulleys to different environmental factors depends on the type of steel used and any additional protective coatings or treatments applied to the pulleys.

2. Corrosion Resistance:

Steel pulleys can be made from corrosion-resistant materials, such as stainless steel or coated steel, to enhance their resistance to rust and corrosion. These materials are particularly suitable for applications where pulleys are exposed to moisture, saltwater, or corrosive chemicals.

3. Extreme Temperatures:

Steel pulleys are capable of withstanding a wide range of temperatures. The specific temperature limits depend on the type of steel used and its heat resistance properties. Standard carbon steel pulleys can typically handle temperatures ranging from -40°C (-40°F) to 200°C (392°F) without significant loss of performance. However, for applications involving extremely high temperatures, specialized alloys or heat-resistant materials may be used.

4. Thermal Expansion:

Steel pulleys are designed to accommodate thermal expansion and contraction that occurs with temperature changes. This allows the pulleys to maintain their structural integrity and performance even when subjected to temperature variations.

5. Insulation and Cooling:

In certain applications where extreme temperatures are present, additional insulation or cooling measures may be implemented to protect the steel pulleys. Insulation materials can help minimize heat transfer to the pulleys, while cooling systems such as air circulation or liquid cooling can dissipate excess heat generated during operation.

6. Application Considerations:

While steel pulleys are generally robust and can withstand harsh environmental conditions and extreme temperatures, it’s essential to consider the specific application requirements. Factors such as the duration and frequency of exposure to extreme conditions, the mechanical loads applied, and the presence of any corrosive agents should be taken into account to ensure the pulleys are appropriately selected and maintained.

In summary, steel pulleys are designed to withstand harsh environmental conditions and a wide range of temperatures. Their resistance to corrosion, durability, and thermal properties make them suitable for various industrial applications. However, for extreme conditions, it may be necessary to choose specialized materials or implement additional protective measures to ensure optimal performance and longevity.

What environmental factors should be considered when using steel pulleys in outdoor applications?

When using steel pulleys in outdoor applications, several environmental factors should be considered. Here’s a detailed explanation:

1. Corrosion:

Outdoor environments often expose steel pulleys to moisture, humidity, rain, and other corrosive elements. It is crucial to select pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, to prevent rust and corrosion. Regular inspection and maintenance of pulleys, including cleaning and applying protective coatings, can help mitigate the effects of corrosion.

2. UV Exposure:

Steel pulleys used in outdoor applications are exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV rays can degrade the materials and weaken the pulleys over time. UV-resistant coatings or finishes can be applied to the pulleys to protect them from UV damage. Additionally, using pulley covers or enclosures can provide additional UV protection.

3. Temperature Extremes:

Outdoor environments can experience temperature extremes, including high heat or freezing temperatures. Steel pulleys should be designed to withstand these temperature variations without compromising their structural integrity. Pulleys made from materials with high-temperature resistance, such as heat-treated steels or alloys, can be employed in applications with elevated temperatures. In cold climates, consideration should be given to the potential effects of low temperatures on pulley performance, such as reduced lubrication effectiveness.

4. Dust and Debris:

Outdoor environments often contain dust, dirt, and debris, which can accumulate on steel pulleys and affect their operation. Regular cleaning and maintenance of the pulleys are essential to prevent the buildup of contaminants that can cause increased friction and wear. Protective covers or seals can be used to minimize the ingress of dust and debris into the pulley components.

5. Moisture and Humidity:

Moisture and humidity in outdoor environments can impact the performance of steel pulleys. Excessive moisture can lead to corrosion, rust, or the deterioration of lubricants. It is important to consider the environmental conditions and choose pulleys that are designed to withstand moisture and humidity. Sealed bearings, waterproof coatings, and proper lubrication can help protect the pulleys from moisture-related issues.

6. Vibration and Shock:

Outdoor applications may involve machinery or equipment that generates vibration and shock loads. Steel pulleys should be designed to withstand these dynamic forces without failure or premature wear. Reinforced construction, precision balancing, and appropriate mounting techniques can help minimize the impact of vibration and shock on the pulleys.

7. Environmental Regulations:

Compliance with environmental regulations is crucial when using steel pulleys in outdoor applications. Certain environments may have specific regulations related to pollution prevention, noise levels, or the use of hazardous materials. It is important to ensure that the selection, installation, and operation of steel pulleys align with applicable environmental regulations.

By considering these environmental factors and taking appropriate measures, such as selecting corrosion-resistant materials, applying protective coatings, regular maintenance, and adhering to environmental regulations, the performance and longevity of steel pulleys in outdoor applications can be optimized.

How does the design of steel pulleys impact their load-bearing capacity and efficiency?

The design of steel pulleys plays a crucial role in determining their load-bearing capacity and efficiency. Here’s a detailed explanation:

1. Diameter and Width:

The diameter and width of a steel pulley directly impact its load-bearing capacity. Larger diameter pulleys distribute the load over a greater surface area, reducing stress and increasing the pulley’s capacity to handle heavier loads. Similarly, wider pulleys provide more contact area for the belt, rope, or cable, allowing for improved load distribution and increased load-bearing capacity.

2. Groove Profile:

The groove profile of a steel pulley affects its efficiency and load-bearing capacity. Different groove profiles, such as V-shaped, U-shaped, or flat, are designed to accommodate specific types of belts, ropes, or cables. The groove profile should match the corresponding belt or cable to ensure proper engagement, minimize slippage, and maximize the load-carrying capability of the pulley.

3. Flanges and Guards:

Pulleys can be designed with flanges or guards on the sides to prevent the belt, rope, or cable from slipping off during operation. Flanges provide guidance and keep the material being conveyed centered on the pulley, enhancing the load-bearing capacity and efficiency. Guards also protect the belt or cable from external elements, reducing the risk of damage and improving overall performance.

4. Bearing Type and Arrangement:

The type and arrangement of bearings in a steel pulley significantly impact its load-bearing capacity and efficiency. High-quality bearings, such as deep groove ball bearings or roller bearings, reduce friction and enable smooth rotation, enhancing the efficiency of power transmission. Proper bearing arrangement, such as using multiple bearings or incorporating bearing supports, ensures optimal load distribution and improves the pulley’s ability to handle higher loads.

5. Material Selection:

The choice of steel material for pulley construction affects both load-bearing capacity and efficiency. High-strength steel alloys or heat-treated steels provide greater load-carrying capacity and resistance to wear or deformation. The material should be selected based on the specific application requirements, considering factors such as load magnitude, operating conditions, and environmental factors.

6. Balanced Design:

A well-balanced design is essential for efficient and reliable operation. Imbalances in the pulley design can cause vibration, increased wear, and reduced load-bearing capacity. Proper balancing techniques, such as counterweights or precision machining, ensure smooth rotation, minimize stress on the pulley and associated components, and optimize load-bearing capacity.

7. Alignment and Installation:

The proper alignment and installation of steel pulleys are critical for their load-bearing capacity and efficiency. Pulleys should be aligned accurately with the drive system to prevent misalignment-induced stress and premature wear. Correct installation techniques, such as applying proper tension to belts or cables, ensure optimal power transmission and efficient load-bearing performance.

In summary, the design of steel pulleys directly impacts their load-bearing capacity and efficiency through factors such as diameter and width, groove profile, flanges and guards, bearing type and arrangement, material selection, balanced design, and proper alignment and installation. By considering these design aspects, manufacturers can optimize the performance and capabilities of steel pulleys, enabling them to handle higher loads, minimize energy losses, and operate with greater efficiency.

editor by CX

2024-04-17