Product Description

Specifications

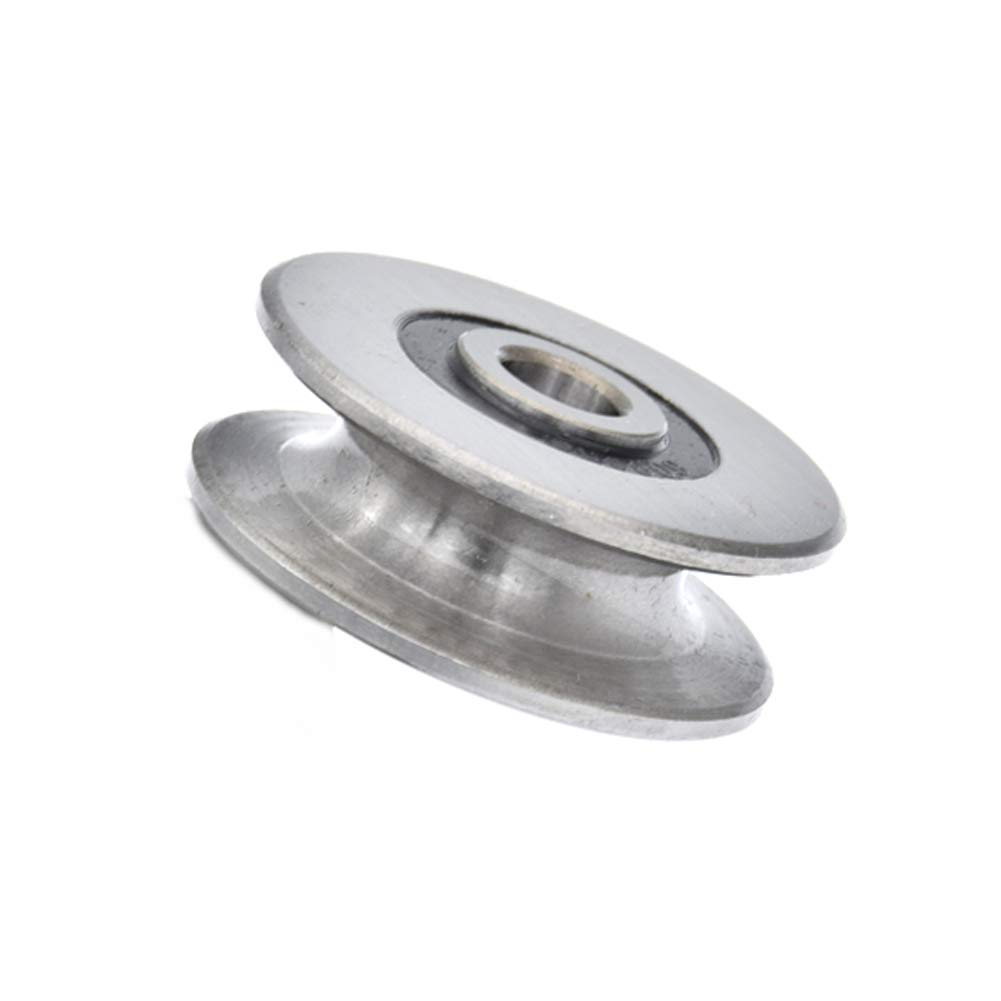

Wire drawing capstan with surface hardness above HRC65

1.Own Designing And Inspecting Team

2.Competitive Factory Price

3.Surface hardness HRC65-68

4. Wear-resisting

5. High Speed

Product Description

Wire drawing capstan

I. Making equipment

Supersonic equipment(HVOF), vaccum treatment

II. Parameters

| No. | Capstan diameter |

| 1 | D400mm |

| 2 | D560mm |

| 3 | D610mm |

| 4 | D800mm |

| 5 | D1000mm |

III. Main characteristics

Super-hard abrasion-resisting: ≥HRC60

top-quality surface roughness: Ra0.1

IV. Suitable machine

Straight wire drawing machine

Pulley type wire drawing machine

Inverted vertical wire drawing machine

Copper wire drawing machine

Aluminum wire drawing machine

V. Photos of wire drawing block

Packaging & Shipping

We can pack it by pallet, or according to the customers’ specific requirements.

Our Services

In order to guarantee the customers are able fully to operate the machine, if the customer need, we can help customer training, includes:

(1) Correct operating mode

(2) Correct maintenance way

(3) Remove simple proble

All the products of our company have already been widely used in metal products area.

Any doubt Please contact us.

Steven Shi

Company Information

All the products of our company are manufactured according eo the national industry standard, enterprise standard and advanced international group standard, and have already been widely used in metal products area.

FAQ

If you have any interest in our machines, please feel free to contact with us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | All Life |

|---|---|

| Warranty: | 1 Year |

| Type: | LZ Straight-Line Metal Drawing Machine |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can steel pulleys withstand harsh environmental conditions and extreme temperatures?

Steel pulleys are known for their durability and ability to withstand a wide range of environmental conditions, including harsh environments and extreme temperatures. Here’s a detailed explanation:

1. Harsh Environmental Conditions:

Steel pulleys are designed to be resistant to various environmental factors, such as moisture, chemicals, dust, and abrasives. They are commonly used in industries like mining, construction, and manufacturing, where they may be exposed to harsh conditions. The specific resistance of steel pulleys to different environmental factors depends on the type of steel used and any additional protective coatings or treatments applied to the pulleys.

2. Corrosion Resistance:

Steel pulleys can be made from corrosion-resistant materials, such as stainless steel or coated steel, to enhance their resistance to rust and corrosion. These materials are particularly suitable for applications where pulleys are exposed to moisture, saltwater, or corrosive chemicals.

3. Extreme Temperatures:

Steel pulleys are capable of withstanding a wide range of temperatures. The specific temperature limits depend on the type of steel used and its heat resistance properties. Standard carbon steel pulleys can typically handle temperatures ranging from -40°C (-40°F) to 200°C (392°F) without significant loss of performance. However, for applications involving extremely high temperatures, specialized alloys or heat-resistant materials may be used.

4. Thermal Expansion:

Steel pulleys are designed to accommodate thermal expansion and contraction that occurs with temperature changes. This allows the pulleys to maintain their structural integrity and performance even when subjected to temperature variations.

5. Insulation and Cooling:

In certain applications where extreme temperatures are present, additional insulation or cooling measures may be implemented to protect the steel pulleys. Insulation materials can help minimize heat transfer to the pulleys, while cooling systems such as air circulation or liquid cooling can dissipate excess heat generated during operation.

6. Application Considerations:

While steel pulleys are generally robust and can withstand harsh environmental conditions and extreme temperatures, it’s essential to consider the specific application requirements. Factors such as the duration and frequency of exposure to extreme conditions, the mechanical loads applied, and the presence of any corrosive agents should be taken into account to ensure the pulleys are appropriately selected and maintained.

In summary, steel pulleys are designed to withstand harsh environmental conditions and a wide range of temperatures. Their resistance to corrosion, durability, and thermal properties make them suitable for various industrial applications. However, for extreme conditions, it may be necessary to choose specialized materials or implement additional protective measures to ensure optimal performance and longevity.

How does the quality and precision of steel pulley components affect their performance?

The quality and precision of steel pulley components have a significant impact on their performance. Here’s a detailed explanation:

1. Load Capacity:

High-quality steel pulley components are engineered to withstand specific load capacities. The use of high-grade steel with appropriate strength and hardness ensures that the pulley can handle the intended loads without deformation or failure. Precision in manufacturing processes ensures consistent performance and reliable load-bearing capabilities.

2. Durability and Longevity:

Precision manufacturing techniques and the use of high-quality materials enhance the durability and longevity of steel pulley components. Components manufactured to precise specifications are less prone to wear, fatigue, and premature failure. High-quality steel with proper heat treatment and surface finishes improves resistance to corrosion, abrasion, and other forms of degradation, extending the lifespan of the pulley.

3. Smooth Operation:

Precision in the design and manufacturing of steel pulley components contributes to smooth operation. Well-machined components ensure proper alignment, balance, and concentricity, reducing friction and minimizing vibrations. Smooth operation enhances efficiency, reduces power losses, and extends the lifespan of associated equipment, such as belts, bearings, and drives.

4. Reduction of Noise and Vibration:

Poorly manufactured or low-quality steel pulley components can generate excessive noise and vibration during operation. Precision manufacturing techniques, such as accurate machining and balancing, help minimize vibrations and noise levels. This improves operator comfort, reduces equipment fatigue, and promotes a safer and more productive work environment.

5. Belt Tracking and Tensioning:

Precision in the design and manufacture of steel pulley components plays a crucial role in belt tracking and tensioning. Components with accurate dimensions and smooth surfaces ensure proper alignment and contact with the belt, facilitating efficient power transmission and minimizing belt slippage. Precise tensioning mechanisms and adjustments allow for optimal belt tension, reducing wear and extending belt life.

6. Compatibility and Interchangeability:

High-quality steel pulley components are designed and manufactured to precise standards, ensuring compatibility and interchangeability with other components and systems. This allows for easier installation, replacement, and maintenance. Components that meet standardized dimensions and tolerances can be readily sourced and integrated into existing equipment or systems.

7. Safety and Reliability:

The quality and precision of steel pulley components directly influence the safety and reliability of the overall system. Components manufactured to high standards minimize the risk of sudden failures, malfunctions, or accidents. Reliable performance of pulley components enhances the overall reliability of equipment and reduces the likelihood of costly downtime or maintenance.

In summary, the quality and precision of steel pulley components are critical factors in determining their performance. High-quality components offer superior load capacity, durability, smooth operation, reduced noise and vibration, optimized belt tracking and tensioning, compatibility and interchangeability, as well as enhanced safety and reliability. It is essential to source steel pulley components from reputable manufacturers that adhere to stringent quality control measures and employ precision manufacturing techniques.

Can you explain the advantages of using steel pulleys in lifting and tensioning tasks?

Using steel pulleys in lifting and tensioning tasks offers several advantages. Here’s a detailed explanation:

1. Strength and Durability:

Steel pulleys are known for their exceptional strength and durability. They can withstand heavy loads and high tensions without deformation or failure. This makes them ideal for lifting and tensioning tasks where robust components are essential to ensure safety and reliability.

2. Load Handling Capacity:

Steel pulleys have high load handling capacities, allowing them to handle substantial weights and tensions. They are designed to distribute the load evenly across the pulley, minimizing stress and preventing overload on individual components. This capability is crucial in lifting and tensioning applications that involve heavy objects or high forces.

3. Resistance to Wear and Corrosion:

Steel pulleys offer excellent resistance to wear and corrosion. They can withstand repeated use and exposure to harsh environmental conditions without significant deterioration. This resistance ensures the longevity of the pulleys, reducing maintenance requirements and increasing their lifespan.

4. Precise Alignment and Tracking:

Steel pulleys provide precise alignment and tracking of ropes, cables, or belts. They are manufactured with tight tolerances to ensure smooth movement and minimize friction. This precise alignment is crucial in lifting and tensioning tasks where accurate positioning and controlled movement are required.

5. Reduced Friction and Energy Loss:

Steel pulleys are designed to reduce friction and energy loss in lifting and tensioning systems. They incorporate smooth surfaces and high-quality bearings or bushings to minimize frictional resistance. By reducing friction, steel pulleys enhance the efficiency of the system, allowing for easier operation and energy savings.

6. Compatibility with Various Rope or Cable Types:

Steel pulleys are compatible with a wide range of rope or cable types, including steel cables, synthetic ropes, or high-strength fibers. They can accommodate different diameters and configurations, providing flexibility in selecting the appropriate rope or cable for specific lifting or tensioning tasks.

7. Safety and Reliability:

Using steel pulleys in lifting and tensioning tasks ensures safety and reliability. Their strength, durability, and load handling capacities contribute to the overall safety of the system, minimizing the risk of accidents or equipment failure. Additionally, their precise alignment and tracking reduce the likelihood of rope slippage or misalignment, ensuring secure and reliable operation.

In summary, the advantages of using steel pulleys in lifting and tensioning tasks include their strength, durability, high load handling capacities, resistance to wear and corrosion, precise alignment and tracking, reduced friction and energy loss, compatibility with various rope or cable types, and overall safety and reliability. These advantages make steel pulleys a preferred choice in applications where heavy loads, precise movement, and dependable performance are essential.

editor by CX

2024-04-13