Product Description

Product Description

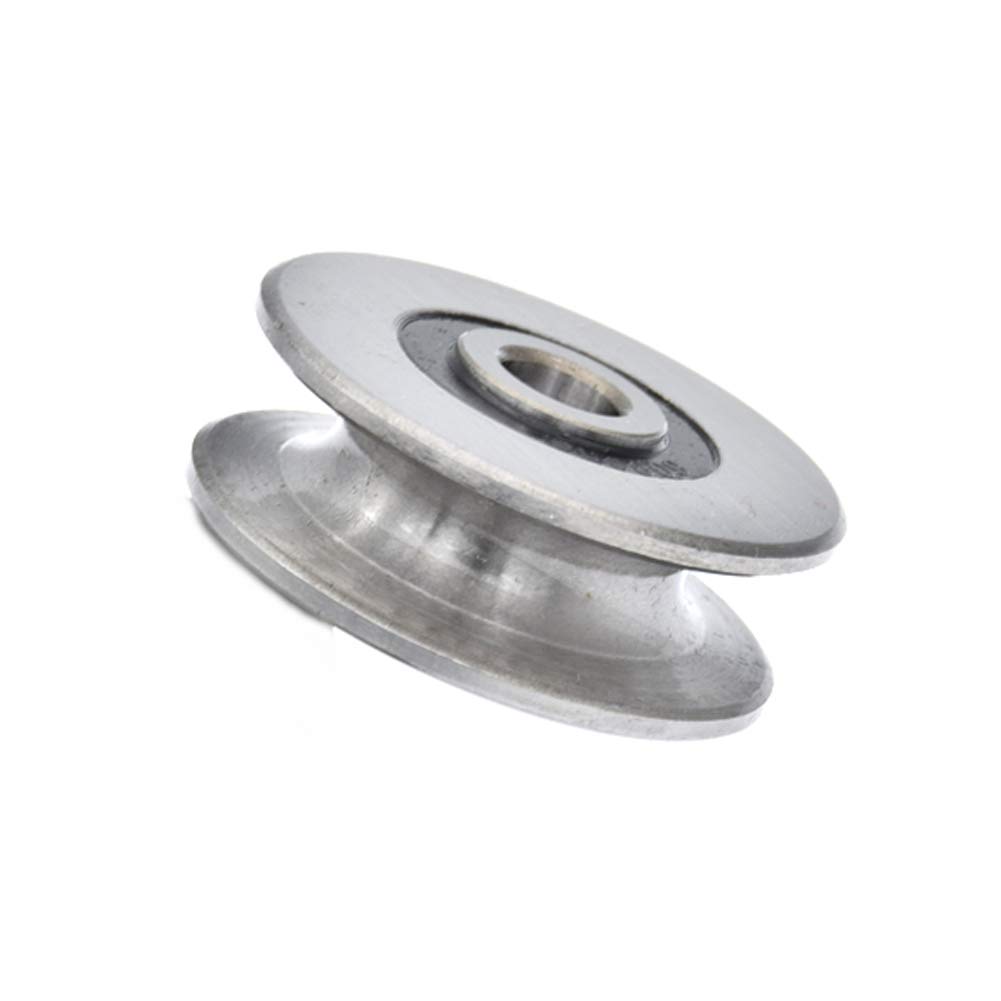

Sheave features:

| Material | Q235B, Q345B, 35#, 45#, 60#, SSW-QR1, S45C |

| Groove surface quench | HRC45-55 |

| Groove surface quench depth | 2mm-2.5mm |

| groove MT after heat treatment and welding line UT and MT | |

| Max processing diameter | 2, 000mm |

| Short production cycle | |

| It is used for crane equipment, port equipment, oil drilling rig and so on | |

Product Parameters

| Code | Wire rope diameter(mm) | Main dimension(mm) | Weight for reference(kg) | ||||||

| D | D1 | R | b | W | D2 | B | |||

| BX1282 | 10-14 | 400 | 445 | 7 | 37 | 28 | 60 | 66 | 20 |

| BX2282 | >14-19 | 500 | 560 | 10 | 50 | 38 | 85 | 78 | 34 |

| BX3282 | >19-23.5 | 630 | 701 | 12 | 60 | 46 | 100 | 94 | 60 |

| BX4282 | >23.5-30 | 800 | 890 | 15 | 73 | 57 | 140 | 110 | 108 |

| BX5282 | >23.5-30 | 1000 | 1112 | 19 | 92 | 72 | 170 | 136 | 187 |

| BX6282 | >30-37 | 1120 | 1246 | 22 | 104 | 82 | 170 | 136 | 239 |

| BX7282 | >43-50 | 1400 | 1552 | 26 | 123 | 98 | 200 | 154 | 454 |

| BX8282 | >50-58 | 1600 | 1772 | 29 | 135 | 110 | 200 | 154 | 594 |

Production Profile

About Us

About Us

As a company of industries and trading integration with ISO 9001-2008 Certificate, HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. Has been in manufacturing material handling equipment parts for many years, with professional experience.

Our Service:

If you are interested in any of our products, please contact me freely! Warmly Welcomed your visit to our factory in China, OEM service will be ok.

Application

Customer Visiting

Certifications

Packaging & Shipping

Services:

Best Services For You

1) We can provide OEM service and design for you

2) We can pack the goods according to your requirement

3) We test the quality of all products before delivery

4) We guarantee our reply in 24 hours of working day

5) We can communicate with you in different languages

6) High quality, best price, punctual shipment, good after-sale service will be guaranteed.

FAQ:

Q: What information should I provide if I want to order the products?

1) Product information: Quantity, specification

2) Delivery time required.

3) Shipping information: Company name, address, phone number, destination seaport/air port.

4) Forwarder’s contact details if there is any in China.

Q: How about your payment terms?

A: 30% -50%deposit, with the balance before delivery, we accept T/T and L/C at sight.

Q: Can I use our own logo?

A: Yes, we can produce by using your own logo if you need.

Q: How about sample & MOQ policy?

A: Welcome sample order. MOQ can be 1 set.

Q: What is your lead time for your goods?

A: Normally 30 days after confirmed order,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Double Beam Crane, Gantry Crane, Bridge Crane, Tower Crane, Single Grinder Crane, Lifting Platform, Small Crane |

|---|---|

| Type: | Electric Hoist |

| Sling Type: | Wire Rope |

| Lift Speed: | 2~8m/min |

| Maximum Lifting Height: | 20m |

| Chain Falls: | 1 |

| Customization: |

Available

| Customized Request |

|---|

How do steel pulleys enhance the precision and control of various mechanical operations?

Steel pulleys play a crucial role in enhancing the precision and control of various mechanical operations. Here’s a detailed explanation:

1. Power Transmission:

Steel pulleys are used in conjunction with belts, ropes, or cables to transmit power from one component to another. By utilizing the mechanical advantage of pulleys, it becomes possible to control and regulate the speed, torque, and direction of the transmitted power. This enables precise control over the mechanical operation and facilitates the achievement of desired outcomes.

2. Mechanical Advantage:

Steel pulleys leverage the concept of mechanical advantage to enhance precision and control. The ratio of the diameters or number of grooves in the pulley system determines the mechanical advantage achieved. By selecting the appropriate pulley size and configuration, mechanical operations can be fine-tuned to optimize performance and control variables such as speed, force, and motion.

3. Speed Control:

Steel pulleys, especially those with variable speed capabilities, enable precise speed control in mechanical operations. By adjusting the effective diameter of the pulley, the rotational speed of the driven component can be modified. This is particularly useful in applications where speed regulation is critical, such as in machinery used for manufacturing, processing, or automation.

4. Torque Transfer:

Pulleys facilitate the transfer of torque from the driving component to the driven component. The size and configuration of the pulleys, along with the tension in the connecting belt or cable, determine the torque transmitted. By carefully selecting the pulley system, the torque can be controlled and distributed as required, ensuring precise and reliable torque transfer for mechanical operations.

5. Synchronization:

In certain applications, precise synchronization of mechanical operations is essential. Steel pulleys, when used in conjunction with timing belts or chains, enable accurate synchronization between multiple components. This is commonly seen in applications such as conveyor systems, robotic arms, or printing presses, where coordinated motion is critical for proper functioning and precision.

6. Control over Mechanical Loads:

Steel pulleys provide control over mechanical loads by managing tension and distributing forces. By properly tensioning the belts, ropes, or cables, the pulleys ensure that the load is evenly distributed across the system, minimizing the risk of slippage, excessive wear, or component failures. This control over mechanical loads enhances the precision and reliability of mechanical operations.

7. Reducing Vibration and Noise:

Steel pulleys, when properly designed and balanced, help reduce vibration and noise generated during mechanical operations. Vibration and noise can negatively impact precision and control, leading to suboptimal performance or discomfort. By incorporating features such as dynamic balancing and precision machining, steel pulleys minimize vibrations and contribute to smoother, quieter mechanical operations.

In summary, steel pulleys enhance the precision and control of various mechanical operations by facilitating power transmission, leveraging mechanical advantage, enabling speed control, ensuring torque transfer, enabling synchronization, managing mechanical loads, and reducing vibration and noise. Their versatility and ability to fine-tune mechanical systems make them invaluable components in a wide range of industries and applications.

What environmental factors should be considered when using steel pulleys in outdoor applications?

When using steel pulleys in outdoor applications, several environmental factors should be considered. Here’s a detailed explanation:

1. Corrosion:

Outdoor environments often expose steel pulleys to moisture, humidity, rain, and other corrosive elements. It is crucial to select pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, to prevent rust and corrosion. Regular inspection and maintenance of pulleys, including cleaning and applying protective coatings, can help mitigate the effects of corrosion.

2. UV Exposure:

Steel pulleys used in outdoor applications are exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV rays can degrade the materials and weaken the pulleys over time. UV-resistant coatings or finishes can be applied to the pulleys to protect them from UV damage. Additionally, using pulley covers or enclosures can provide additional UV protection.

3. Temperature Extremes:

Outdoor environments can experience temperature extremes, including high heat or freezing temperatures. Steel pulleys should be designed to withstand these temperature variations without compromising their structural integrity. Pulleys made from materials with high-temperature resistance, such as heat-treated steels or alloys, can be employed in applications with elevated temperatures. In cold climates, consideration should be given to the potential effects of low temperatures on pulley performance, such as reduced lubrication effectiveness.

4. Dust and Debris:

Outdoor environments often contain dust, dirt, and debris, which can accumulate on steel pulleys and affect their operation. Regular cleaning and maintenance of the pulleys are essential to prevent the buildup of contaminants that can cause increased friction and wear. Protective covers or seals can be used to minimize the ingress of dust and debris into the pulley components.

5. Moisture and Humidity:

Moisture and humidity in outdoor environments can impact the performance of steel pulleys. Excessive moisture can lead to corrosion, rust, or the deterioration of lubricants. It is important to consider the environmental conditions and choose pulleys that are designed to withstand moisture and humidity. Sealed bearings, waterproof coatings, and proper lubrication can help protect the pulleys from moisture-related issues.

6. Vibration and Shock:

Outdoor applications may involve machinery or equipment that generates vibration and shock loads. Steel pulleys should be designed to withstand these dynamic forces without failure or premature wear. Reinforced construction, precision balancing, and appropriate mounting techniques can help minimize the impact of vibration and shock on the pulleys.

7. Environmental Regulations:

Compliance with environmental regulations is crucial when using steel pulleys in outdoor applications. Certain environments may have specific regulations related to pollution prevention, noise levels, or the use of hazardous materials. It is important to ensure that the selection, installation, and operation of steel pulleys align with applicable environmental regulations.

By considering these environmental factors and taking appropriate measures, such as selecting corrosion-resistant materials, applying protective coatings, regular maintenance, and adhering to environmental regulations, the performance and longevity of steel pulleys in outdoor applications can be optimized.

What are steel pulleys, and how are they used in various applications?

Steel pulleys are mechanical devices made primarily from steel that are used to guide or redirect ropes, cables, or belts in various applications. Here’s a detailed explanation:

1. Construction and Engineering:

In construction and engineering, steel pulleys are commonly used in hoisting and lifting systems. They provide a stable and durable mechanism for raising and lowering heavy loads, such as construction materials, equipment, or machinery. Steel pulleys used in these applications are designed to withstand high loads and harsh operating conditions.

2. Industrial Machinery and Manufacturing:

Steel pulleys find extensive use in industrial machinery and manufacturing processes. They are employed in conveyor systems to move materials or products along assembly lines. Steel pulleys with different diameters and groove configurations are used to facilitate belt or chain movement, ensuring efficient and reliable material handling.

3. Automotive and Transportation:

In the automotive and transportation industries, steel pulleys are utilized in various applications. They are commonly found in engines as part of the accessory drive system, where they drive components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure smooth operation and reliable power transmission in these critical systems.

4. Gym and Fitness Equipment:

Steel pulleys are integral components of gym and fitness equipment, such as cable machines or weightlifting systems. They enable smooth and controlled movement of cables or belts, allowing users to perform exercises safely and effectively. Steel pulleys used in fitness equipment are designed to withstand repetitive loads and provide long-lasting performance.

5. Material Handling and Rigging:

Steel pulleys play a crucial role in material handling and rigging applications. They are used in systems such as cranes, winches, and lifting equipment to redirect cables or ropes, enabling the lifting and movement of heavy objects. Steel pulleys in these applications are engineered to handle substantial loads and ensure safe and efficient material handling.

6. Entertainment and Theatrical Rigging:

In the entertainment industry, steel pulleys are utilized in theatrical rigging systems. They are employed to control the movement of stage components, lighting fixtures, curtains, and other theatrical elements. Steel pulleys in this context must meet stringent safety standards and provide precise positioning and smooth operation.

7. Recreational Activities:

Steel pulleys are also utilized in various recreational activities. For example, in zip line courses or rope courses, steel pulleys are used to guide participants along the course safely. In rock climbing, steel pulleys may be employed as part of hauling systems or belay devices. These pulleys are designed to withstand high forces and ensure reliable performance in adventurous settings.

Steel pulleys offer strength, durability, and reliability in a wide range of applications. Their ability to handle heavy loads, provide smooth operation, and withstand harsh conditions makes them indispensable in industries such as construction, manufacturing, automotive, fitness, entertainment, and recreational activities.

editor by CX

2024-04-15