Product Description

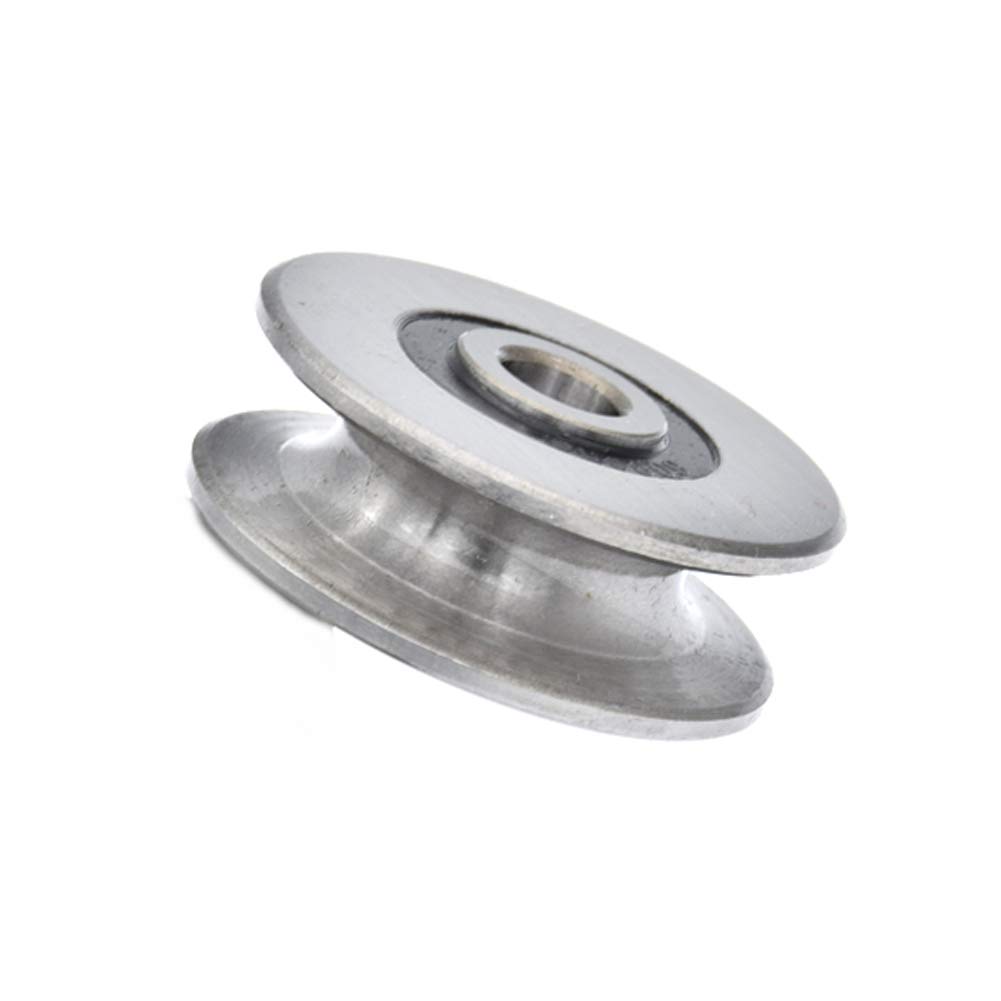

Competitive Price Heavy Duty Gravity Roller SS304 Light Steel Idler Pulley

Product Description

Idler rollers, or sometimes simply known as conveyor rollers, are cylindrical-shaped bars that run along and underneath a conveyor belt. There are many different types of idler rollers with varying functions.

Usually, idler rollers aid in the supporting of weight and impact of the materials being transported along the belt. They also assist in the smooth, continuous movement of the material along the belt.

Idler rollers can be self-aligning and assist in maintaining the belt tracking. Depending on the structure and shape of the conveyor belt, the rollers are usually positioned within a metal frame and are known as idler sets.

Detailed Photos

Product Parameters

| Diameter | 60-219mm |

| Length | 100-3500mm |

| Tube | Q235(GB) |

| Shaft | 45# steel(GB) equal to C45 |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RZ&2Z wigh C3 clearance |

| Grease | Lithium soap type grease,grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal |

| Lubrication | Grease is Lithium soap type grease with Rust Inhibitors |

| Welding | Mixed gas shielded arc welding end |

|

Painting |

Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

|

D(mm) |

L(mm) |

Bearing model |

|

89 |

180,190,200,235,240,250,275,280,305,215,350,375,380,455,465,600,750,950,1150 |

204 |

|

108 |

190,200,240,250,305,315,360,375,380,455,465,525,530,600,700,750,790,800,950,1150,1400,1600 |

|

|

133 |

305,375,380,455,465,525,530,600,700,750,790,800,900,950,1000,1100,1150,1400,1600,1800,2000,2200 |

|

|

159 |

375,380,455,465,525,530,600,700,750,790,800,900,1000,1050,1100,1120,1150,1250,1400,1500,1600,1700,1800,2000,2200,2500,2800,3000,3150 |

|

|

193.7 |

2200,2500,2800,3000,3150,3350 |

308 310 |

|

217 |

600,640,1050,1120,1600,1700,3150,3350 |

308 310 |

Certifications

Packaging & Shipping

Company Profile

ZheJiang CHINAMFG Rubber Products Co., Ltd is a leading professional manufacturer of conveyor belts & conveyor accessories in China. The main workshops cover 20,000 square CHINAMFG in the total 60,000 square CHINAMFG of the plant. The applied technology and equipment in the advanced production lines are state of the art in the industry. The sales headquarters is located in the capital of China, ZheJiang with branches in domestic and abroad.

It specializes in following 3 series: 1) Heavy-duty Conveyor Belt, including universal EP/NN and CC Belt, Chevron Belt, Oil Resistant Belt, Abrasion Resistant Belt, Heat Resistant Belt, Fire Resistant Belt, Chemical Resistant Belt, Sidewall Belt, Flat Transmission Belts, 2) Rubber Sheets, including SBR, NBR, NR, CR, EDPM, Rubber With Insertion 3) Conveyor accessories. These 3 series of products conform to RMA, DIN, ASTM and ISO specifications.

Its products, honored with “The most Advanced level of Products” by the Committee of Science and Technology, have been widely used in mining and quarrying, power stations, steel plants, bulk cargo terminals, cement industry, and other material handling fields. With great success in domestic market, it has been focusing on global market with several hundreds of foreign valued customers in Asia, South America, North America, Africa and Europe.

The company mission:

1.Supply one-stop outstanding service to global customers.

2. Engage in complete solutions with conveyor belting and power transmission belting.

3. Persist in technology improvement and quality control in the whole process of production and service.

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Parallel Conveyor Idler |

| Dimension(L*W*H): | Variable |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

Can steel pulleys be customized or modified to meet specific load requirements?

Yes, steel pulleys can be customized or modified to meet specific load requirements. Here’s a detailed explanation:

1. Size and Dimensions:

Steel pulleys can be customized in terms of size and dimensions to accommodate specific load requirements. The diameter, width, and overall geometry of the pulley can be adjusted to ensure optimal load-bearing capacity and compatibility with the application. Customization allows for precise matching of the pulley dimensions to the load demands, promoting efficient and reliable operation.

2. Material Selection:

The choice of steel material for the pulley can be tailored based on specific load requirements. Different steel alloys and compositions have varying strength, hardness, and wear resistance properties. By selecting the appropriate steel material, the pulley can be optimized to handle higher loads, resist wear, and withstand harsh operating conditions.

3. Bearing Type:

Steel pulleys can be customized with different bearing types to handle specific load requirements. The bearing type plays a crucial role in supporting the load and facilitating smooth rotation of the pulley. Options such as deep groove ball bearings, tapered roller bearings, or spherical roller bearings can be selected based on load capacity, rotational speed, and environmental conditions.

4. Coatings and Surface Treatments:

Coatings and surface treatments can be applied to steel pulleys to enhance their load-bearing capabilities. For example, pulleys can be coated with corrosion-resistant materials or treated with specialized coatings to reduce friction and wear. These customized surface treatments improve the overall performance and longevity of the pulley, especially in demanding load conditions.

5. Reinforcements and Reinforcement Materials:

In situations where standard steel pulleys may not meet the desired load requirements, reinforcements can be added or alternative reinforcement materials can be used. Reinforcing the pulley structure with additional steel components or incorporating materials such as carbon fiber or reinforced polymers can significantly increase the load capacity and strength of the pulley.

6. Dynamic Balancing:

Customization of steel pulleys can include dynamic balancing, which is essential for high-speed applications or when precise rotation is required. Dynamic balancing ensures that the pulley’s mass is evenly distributed, minimizing vibrations and reducing the risk of premature wear or component failure due to unbalanced forces.

7. Specialized Designs:

In some cases, specialized designs or modifications may be required to meet specific load requirements. This could involve incorporating features such as reinforced hub sections, flanges, or additional grooves to distribute the load more effectively. Custom designs can be created through engineering analysis and collaboration between the pulley manufacturer and the end-user.

It’s important to note that customization and modification of steel pulleys should be done in consultation with experienced engineers or pulley manufacturers. They can provide expertise in assessing the load requirements, selecting suitable customization options, and ensuring compliance with relevant industry standards and safety guidelines.

In summary, steel pulleys can be customized or modified in terms of size, material, bearing type, coatings, reinforcements, dynamic balancing, and specialized designs to meet specific load requirements. Customization enhances the load-bearing capacity, durability, and overall performance of steel pulleys, making them suitable for a wide range of applications in various industries.

How do steel pulleys compare to other materials, such as plastic or aluminum, in various scenarios?

Steel pulleys, plastic pulleys, and aluminum pulleys each have their own advantages and considerations in different scenarios. Here’s a detailed comparison:

1. Strength and Durability:

Steel pulleys generally offer higher strength and durability compared to plastic or aluminum pulleys. Steel has excellent load-bearing capacity and can withstand heavy loads and high forces without deformation. Plastic pulleys are lightweight but may have lower strength and may not be suitable for heavy-duty applications. Aluminum pulleys offer a good balance between strength and weight, but they may not be as durable as steel pulleys in certain demanding scenarios.

2. Corrosion Resistance:

Steel pulleys often exhibit better corrosion resistance compared to aluminum pulleys, especially when made from stainless steel or galvanized steel. Plastic pulleys are inherently corrosion-resistant, which makes them suitable for applications where exposure to moisture or chemicals is a concern. Aluminum pulleys may require additional protective coatings or treatments to enhance their corrosion resistance.

3. Weight:

Plastic and aluminum pulleys are generally lighter than steel pulleys. In applications where weight reduction is critical, such as in industries like aerospace or automotive, plastic or aluminum pulleys may be preferred. However, it is important to consider the load requirements and select a material that can handle the anticipated forces without compromising safety or performance.

4. Friction and Wear:

Steel pulleys typically have smoother surfaces and better wear resistance compared to plastic pulleys. The smooth surfaces of steel pulleys reduce friction and wear on the belt or rope, contributing to improved efficiency and longevity. Plastic pulleys may have higher friction coefficients and may require additional lubrication or specialized coatings to reduce wear. Aluminum pulleys can have good wear resistance but may not be as durable as steel pulleys in high-load or abrasive environments.

5. Temperature Resistance:

Steel pulleys generally have better temperature resistance compared to plastic pulleys. Steel can withstand higher temperatures without deformation or loss of strength. Plastic pulleys may have limitations in high-temperature applications due to their lower melting points. Aluminum pulleys have good heat dissipation properties but may experience thermal expansion.

6. Cost:

Steel pulleys are often more cost-effective compared to aluminum pulleys, especially for larger or heavy-duty applications. Plastic pulleys can be cost-effective for certain low-load or non-critical applications. Aluminum pulleys are generally more expensive than steel pulleys but offer advantages in terms of weight savings and specific applications where their properties are advantageous.

7. Noise and Vibration:

Steel pulleys tend to produce less noise and vibration compared to plastic pulleys. Steel’s higher density and rigidity help dampen vibrations and reduce noise levels. Plastic pulleys may generate more noise and vibration, particularly at high speeds or under heavy loads. Aluminum pulleys can offer good vibration damping properties but may not be as effective as steel in certain scenarios.

In summary, the choice between steel, plastic, or aluminum pulleys depends on the specific requirements of the application. Steel pulleys offer superior strength, durability, corrosion resistance, and wear resistance, making them suitable for heavy-duty and demanding scenarios. Plastic pulleys are lightweight, corrosion-resistant, and cost-effective for certain low-load applications. Aluminum pulleys provide a balance between strength and weight, making them advantageous in weight-sensitive applications. Consideration should be given to factors such as load requirements, environmental conditions, temperature, cost, and performance characteristics to determine the most suitable pulley material for a given scenario.

What are some common uses of steel pulleys in industrial and mechanical systems?

Steel pulleys have a wide range of common uses in industrial and mechanical systems. Here’s a detailed explanation:

1. Conveyor Systems:

Steel pulleys are extensively employed in conveyor systems across various industries. They help redirect belts or chains, facilitating the movement of materials or products along assembly lines. Steel pulleys ensure smooth and efficient operation of the conveyor system, allowing for automated material handling in manufacturing, distribution, and logistics.

2. Lifting and Hoisting Equipment:

In lifting and hoisting applications, steel pulleys are vital components of cranes, winches, and lifting equipment. They are used to redirect ropes or cables, enabling the lifting and movement of heavy loads. Steel pulleys ensure reliable and safe lifting operations in industries such as construction, mining, and maritime.

3. Power Transmission Systems:

Steel pulleys play a crucial role in power transmission systems. They are used in conjunction with belts, chains, or cables to transfer rotational motion or power between different components, such as electric motors, engines, and mechanical equipment. Steel pulleys provide efficient power transmission and precise speed control in applications ranging from industrial machinery to automotive engines.

4. Material Handling Equipment:

Various material handling equipment, such as forklifts, cranes, and overhead hoists, utilize steel pulleys. These pulleys enable the movement and positioning of heavy objects, enhancing efficiency and productivity in warehouses, construction sites, and manufacturing facilities.

5. Packaging Machinery:

In packaging machinery, steel pulleys are employed to guide and control the movement of packaging materials, such as films, papers, or foils. They ensure accurate and synchronized feeding, cutting, and sealing processes, contributing to the efficiency and reliability of packaging operations.

6. Automotive Systems:

The automotive industry extensively uses steel pulleys in various systems. They are commonly found in engines as part of the accessory drive system, where they drive components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure reliable power transmission and smooth operation in these critical automotive systems.

7. Agricultural Machinery:

Steel pulleys are utilized in agricultural machinery for tasks such as powering irrigation pumps, operating harvesting equipment, or driving conveyor systems in grain handling facilities. They withstand the demanding agricultural environment and facilitate efficient operations in the farming industry.

8. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems rely on steel pulleys to drive components like blowers and fans. Steel pulleys ensure the efficient and reliable operation of HVAC systems, contributing to temperature control, air circulation, and comfort in residential, commercial, and industrial buildings.

These are just a few examples of the common uses of steel pulleys in industrial and mechanical systems. Their strength, durability, and ability to handle heavy loads make them essential components in numerous applications, contributing to the smooth operation of various industries.

editor by CX

2024-04-19