Product Description

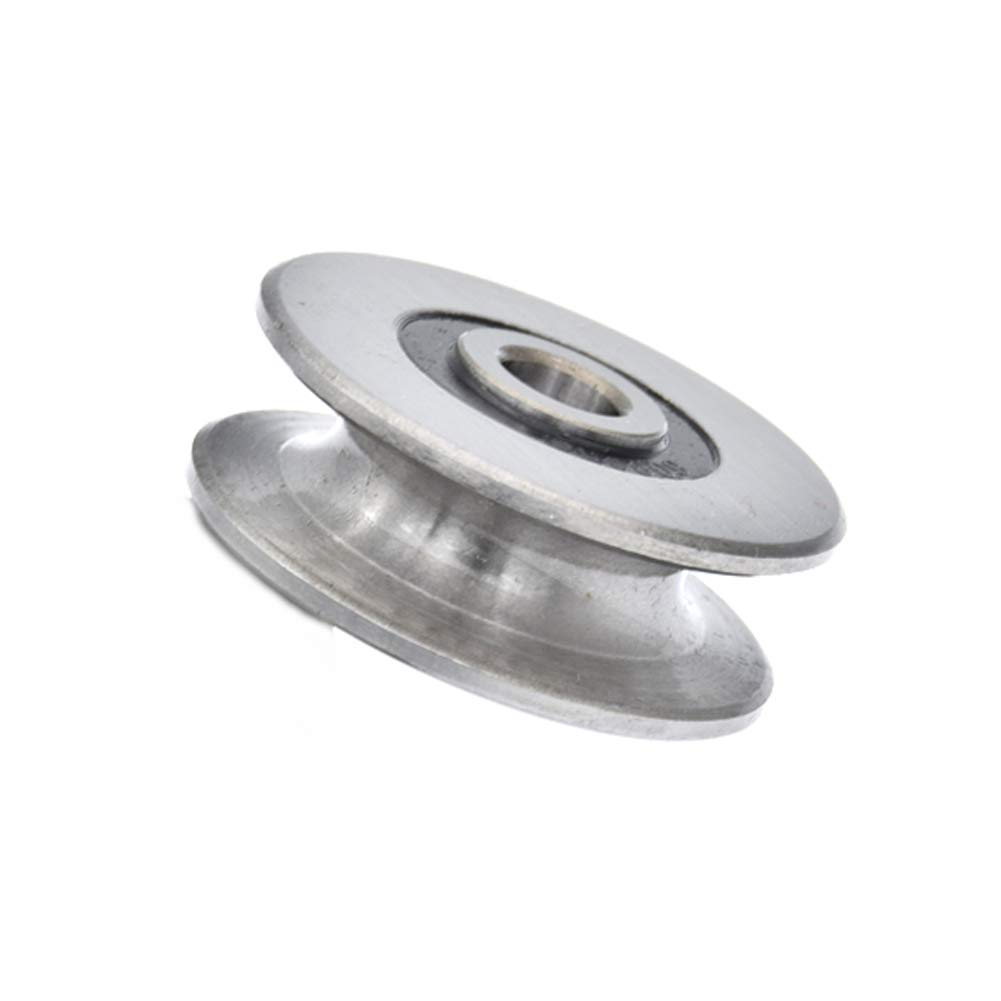

V-groove raised carbon steel bearings double wheel iron pulley

| Product name | Door and window wheel |

| Brand name | ALLY |

| Model number | WW-94 |

| roller Material | Aluminum imitation copper wheel |

| Shell material | aluminum /iron |

| Size | different size,contact us |

| MOQ | 5000 pcs |

| Sample time | Within 3-5 days |

| Delivery time | 20-25 working days |

| Payment | 30% deposit,70% balance before delivery by T/T |

| Shipping port | HangZhou China |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Support |

|---|---|

| Warranty: | Lifetime |

| Splittable: | Unsplittable |

| Surface Treatment: | Zinc Plated |

| Material: | Nylon and Iron |

| MOQ: | 5000PCS |

| Customization: |

Available

| Customized Request |

|---|

What maintenance practices should be followed to ensure the longevity of steel pulleys?

To ensure the longevity and optimal performance of steel pulleys, several maintenance practices should be followed. Here’s a detailed explanation:

1. Regular Inspection:

Perform regular visual inspections of the steel pulleys to identify any signs of wear, damage, or misalignment. Look for cracks, excessive wear on the grooves, or any abnormalities that may affect the pulley’s performance. Promptly address any issues discovered during inspections.

2. Lubrication:

Proper lubrication is essential for reducing friction, preventing excessive wear, and ensuring smooth operation of the pulleys. Follow the manufacturer’s guidelines and apply appropriate lubricants to the bearings and moving parts of the pulleys at recommended intervals.

3. Belt or Cable Tension:

Maintain proper tension in belts, ropes, or cables connected to the pulleys. Incorrect tension can lead to slippage, increased wear, and reduced power transmission efficiency. Refer to the manufacturer’s recommendations or industry standards for the appropriate tension levels.

4. Cleaning:

Regularly clean the steel pulleys to remove dirt, debris, or contaminants that can accumulate on the surfaces. Use appropriate cleaning methods and avoid using abrasive materials that may damage the pulley. Keeping the pulleys clean helps prevent premature wear and ensures smooth operation.

5. Alignment:

Proper alignment of the pulleys is crucial for their longevity. Misaligned pulleys can cause excessive stress, vibration, and accelerated wear. Regularly check the alignment and make adjustments as necessary to ensure that the pulleys are properly aligned with the drive system.

6. Balancing:

If the pulleys are dynamically balanced, ensure that the balance is maintained. Imbalances can lead to vibration, increased stress, and premature failure. If a pulley shows signs of imbalance, consult a professional for corrective measures.

7. Environmental Considerations:

Take into account the environmental conditions in which the pulleys operate. If the environment is corrosive or exposes the pulleys to contaminants, consider using corrosion-resistant materials or implementing protective measures to prevent damage.

8. Record Keeping:

Maintain records of maintenance activities, including inspections, lubrication schedules, and any repairs or replacements. This documentation helps track the maintenance history of the pulleys and informs future maintenance decisions.

9. Professional Assistance:

If you are unsure about any maintenance aspect or encounter significant issues, consult with a qualified professional or the manufacturer for guidance and assistance.

By following these maintenance practices, you can prolong the lifespan of steel pulleys, ensure their reliable operation, and minimize the risk of unexpected failures or downtime.

What is the impact of corrosion resistance in steel pulleys when used in corrosive environments?

Corrosive environments can have a significant impact on steel pulleys, and corrosion resistance plays a crucial role in mitigating these effects. Here’s a detailed explanation:

When steel pulleys are used in corrosive environments, such as those exposed to moisture, humidity, chemicals, or saltwater, they are susceptible to corrosion. Corrosion is a natural electrochemical process that causes the gradual degradation and deterioration of metals.

The impact of corrosion on steel pulleys can be detrimental and lead to several negative consequences:

1. Structural Integrity:

Corrosion can compromise the structural integrity of steel pulleys. It weakens the metal, leading to cracks, pitting, or deformation. As the corrosion progresses, the pulleys may become structurally compromised, increasing the risk of failure or breakage. This can result in safety hazards, equipment downtime, and potential damage to other components.

2. Reduced Performance:

Corroded steel pulleys may exhibit reduced performance in terms of their functionality and efficiency. Corrosion can cause increased friction between the pulley and the belt or rope, leading to higher energy consumption, decreased power transmission efficiency, and accelerated wear of the pulley and the mating components. This can result in decreased overall system performance and increased maintenance requirements.

3. Belt or Rope Damage:

Corrosion on steel pulleys can cause damage to the belt or rope that runs over them. The corroded surfaces may have rough spots, sharp edges, or irregularities that can abrade or tear the belt or rope. This can lead to premature belt or rope failure, necessitating frequent replacements and increasing operational costs.

4. Increased Maintenance and Replacement Costs:

Corrosion-related issues in steel pulleys can result in higher maintenance and replacement costs. Regular cleaning, lubrication, and inspection are required to prevent and manage corrosion. If the pulleys become severely corroded, they may need to be replaced entirely, adding to the maintenance expenses and causing additional downtime for equipment.

5. Environmental Impact:

Corrosion of steel pulleys in corrosive environments can have environmental implications. Corrosion products, such as rust, can contaminate the surrounding environment, including soil, water bodies, or nearby equipment. This can have adverse effects on ecosystems and may require additional cleanup or remediation efforts.

To mitigate the impact of corrosion in steel pulleys used in corrosive environments, it is essential to consider and implement corrosion-resistant measures:

1. Material Selection:

Choosing steel pulleys made from corrosion-resistant materials, such as stainless steel or galvanized steel, can significantly enhance their resistance to corrosion. These materials have protective layers or alloy compositions that provide a barrier against corrosive agents.

2. Protective Coatings:

Applying protective coatings, such as paints, epoxies, or specialized corrosion-resistant coatings, can help create an additional barrier between the steel pulleys and the corrosive environment. These coatings act as sacrificial layers that prevent direct contact between the pulleys and corrosive agents.

3. Regular Maintenance:

Implementing a proactive maintenance program is crucial to prevent and manage corrosion in steel pulleys. Regular cleaning, inspection, and lubrication can help remove corrosive substances, detect early signs of corrosion, and ensure proper functioning of the pulleys.

4. Environmental Controls:

Implementing environmental controls, such as proper ventilation, humidity control, or the use of protective enclosures, can help reduce the exposure of steel pulleys to corrosive elements. Minimizing direct contact with moisture, chemicals, or saltwater can significantly extend the lifespan of the pulleys.

By considering the impact of corrosion and taking appropriate measures to enhance corrosion resistance, the performance, durability, and lifespan of steel pulleys can be significantly improved in corrosive environments.

In which industries and scenarios are steel pulleys commonly employed?

Steel pulleys find widespread use in various industries and scenarios. Here’s a detailed explanation:

1. Construction and Engineering:

Steel pulleys are commonly employed in the construction and engineering industry for lifting and hoisting applications. They are used in cranes, winches, and lifting equipment to redirect ropes or cables, enabling the movement of heavy construction materials, equipment, or machinery.

2. Manufacturing and Industrial Machinery:

In manufacturing and industrial settings, steel pulleys are utilized in conveyor systems to facilitate the movement of materials or products along assembly lines. They are also employed in machinery and equipment for processes such as material handling, packaging, and automation.

3. Automotive and Transportation:

The automotive and transportation industries utilize steel pulleys in various applications. They are commonly found in engines as part of the accessory drive system, driving components such as alternators, water pumps, power steering pumps, and air conditioning compressors. Steel pulleys ensure reliable power transmission and smooth operation in these critical systems.

4. Gym and Fitness Equipment:

Steel pulleys are integral components of gym and fitness equipment, such as cable machines, weightlifting systems, or pulley-based exercise machines. They enable smooth and controlled movement of cables or belts, allowing users to perform exercises safely and effectively.

5. Material Handling and Rigging:

Steel pulleys play a crucial role in material handling and rigging applications. They are used in cranes, winches, and lifting equipment to redirect ropes or cables, enabling the lifting and movement of heavy objects in industries such as construction, manufacturing, logistics, and maritime.

6. Entertainment and Theatrical Rigging:

In the entertainment industry, steel pulleys are employed in theatrical rigging systems. They are used to control the movement of stage components, lighting fixtures, curtains, and other theatrical elements. Steel pulleys in this context must meet stringent safety standards and provide precise positioning and smooth operation.

7. Recreational Activities:

Steel pulleys are utilized in various recreational activities and outdoor adventures. They are commonly found in zip line courses, rope courses, rock climbing setups, and high ropes courses. Steel pulleys enable safe and controlled movement, providing thrilling experiences while ensuring participant safety.

8. Marine and Offshore:

In the marine and offshore industry, steel pulleys are employed in various applications, such as shipboard lifting, mooring systems, and offshore installations. They are designed to withstand harsh marine environments and heavy loads, ensuring reliable performance in demanding offshore operations.

These are just a few examples of the industries and scenarios where steel pulleys are commonly employed. Their versatility, strength, and reliability make them valuable components across a wide range of applications, contributing to the efficiency and functionality of various industries.

editor by CX

2024-04-16